Deep sea drilling is the process of extracting valuable resources, such as oil and gas, from beneath the ocean floor. It involves the use of advanced drilling equipment and technology operated at extreme depths, often exceeding several thousand meters. As a field that presents immense challenges due to the harsh environmental conditions and the technical processes it requires, deep sea drilling demands the utmost precision and reliability from every aspect of its operations.

Slip rings play a crucial role in ensuring the success and efficiency of deep sea drilling processes. Serving as the interface between stationary and rotating components, they facilitate the seamless transfer of electrical power and signals across rotating systems. This functionality is indispensable for a wide array of drilling equipment, including drilling rigs, remotely operated underwater vehicles (ROVs), and submersible pumps — all of which must perform with unwavering precision in these extreme environments.

In the context of deep sea drilling, slip rings enable enhanced operational efficiency, equipment effectiveness, and the ability to endure the punishing conditions that characterize the deep ocean, such as high pressure, corrosive elements, and low or high temperatures. Uncompromising performance and reliability are the cornerstones of slip rings within this domain, making their role in modern deep sea drilling operations both fundamental and indispensable.

Slip Rings: Focusing on Deep Sea Drilling Applications

Deep Sea Drilling Slip Ring Overview

Deep sea drilling slip rings serve the essential function of transmitting electrical power and signals between stationary and rotating parts of various drilling machinery. This crucial function allows perfect coordination among all parts of the drilling machinery, enabling fluid movement and the efficient execution of its critical tasks. Given their significant role, failure or suboptimal performance of slip rings, in any capacity, can lead to considerable performance degradation of the entire drilling operation.

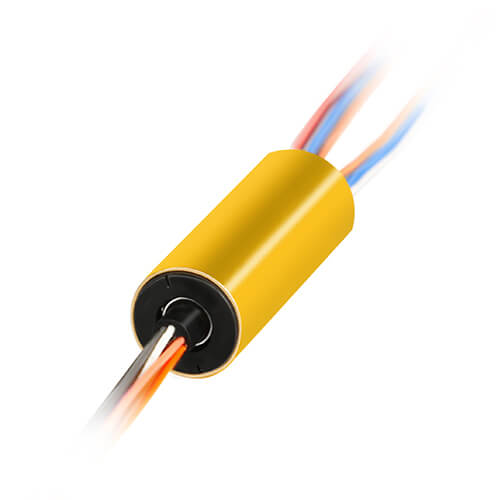

Several types of slip rings are deployed in deep sea drilling activities based on the specific requirements and environmental conditions. For instance, through-bore slip rings are preferred when a large through-hole is needed in the middle to pass hydraulic lines or a shaft. Pancake slip rings, with their slim profile, are chosen when axial length is limited. Capsule slip rings are noted for their compact design and robustness, making them highly valuable for operations where space is a concern, and durability is of the essence.

Components of a Deep Sea Drilling Slip Ring

A deep-sea drilling slip ring is composed of several key components, each tailored to withstand the rigorous demands of underwater operations. These components typically include the rotating ring, stationary brush contacts, a casing, and a core.

The rotating ring is generally made of conductive metal and is attached to the rotating part of the machine. On the other hand, the stationary brush contacts are linked to the stationary part of the equipment and gently brush against the rotating ring to transmit electrical signals and power. The casing serves to protect these integral components from harsh external conditions and the corrosive deep-sea environment. Lastly, the core, usually made of strong, robust material, provides structural stability to the assembly and allows it to endure the substantial physical stress prevalent in deep-sea applications.

Each component in the assembly plays a vital role in ensuring the slip ring’s overall performance and durability. The optimal interaction between these components translates to higher operational efficiency, improved data accuracy, and reduced equipment breakdowns in the challenging deep-sea drilling environment.

Use Cases and Importance of Slip Rings in Deep Sea Drilling

Applications in Drilling Equipment

In the realm of deep sea drilling, the application of slip rings is seen across a multitude of machinery. To begin with, they are a vital part of drilling rigs, enabling the rotation of the drill bit while sustaining the transmission of electrical signals. Besides, they play an essential role in driving underwater winches, allowing the free rotation of winch drums without tangling or constricting cables.

Moreover, Rotary Steerable Systems (RSS), which are keys to the successful navigation of the drill bit in complex well paths, heavily rely on slip rings for seamless power and signal transmission. In Remotely Operated Vehicles (ROVs), slip rings facilitate the signal and power transfers needed for carrying out precise maneuvers and tasks.

Indisputably, slip rings have contributed significantly to the efficiency and effectiveness of deep sea drilling. By facilitating continuous, unrestricted rotation while still transmitting electrical signals and power effectively, they improve the overall operational performance while reducing the risk of costly downtime and component failures.

Types of Slip Rings for Deep Sea Drilling

Several types of slip rings are commonly used in deep sea drilling operations, each offering their unique properties suitable for particular applications. For instance, the through-bore slip rings provide a large central hole that can facilitate the passage of other elements such as hydraulic lines or a shaft.

Pancake slip rings are usually chosen for situations where axial length is limited. They offer a slim profile that makes them compact and space-efficient.

Capsule slip rings, on the other hand, are prized for their robustness and compactness, demonstrating significant durability even in the most challenging environments.

When it comes to selecting slip rings for specific applications, a comparison based on required specifications, environmental conditions, and desired performance becomes crucial. Factors like physical dimensions, number of circuits, voltage and current requirements, and operating speed are among the array of aspects that must be considered in the selection process. In essence, the right slip ring is one that best meets the demanding requirements of deep sea drilling operations while ensuring longevity and reliability.

Specification and Design Considerations for Deep Sea Drilling Slip Rings

Environmental Factors

The environment of deep sea drilling operations poses a suite of challenges to the design and functionality of slip rings. These environments typically come with high pressures, extreme temperatures (both hot and cold), and corrosive conditions due to high salt content. Slip rings used in such conditions need to be designed to withstand these challenges effectively.

Material selection plays a crucial role in the slip rings withstanding these conditions. This often includes using robust and corrosion-resistant materials like stainless steel for casings to protect against salt water and using gold alloy brush wire for optimal conductivity and minimal wear.

Sealing solutions are also pivotal in protecting the conduction parts of the slip ring against environmental threats. The use of IP-rated seals or hermetic seals can ensure that the interior elements remain isolated from external environmental influences, thereby prolonging their functional life.

Electrical and Mechanical Performance

The choice of slip rings for deep-sea drilling operations also hinges on their electrical performance. Given the high-powered machinery involved in these operations, slip rings must have high current and voltage ratings. This necessitates the use of reliable and high-quality electrical contacts, often made of precious metals for their superb conductivity characteristics and resistance to corrosion.

Brush technology, which facilitates the transmission of power and signals between the stationary and rotating components, also needs to be optimized for these harsh environments. They must ensure stable, low-resistance contact to facilitate efficient, uninterrupted data and power transmission.

Mechanical design considerations too hold significant importance – from the ease of installation to maintenance accessibility. The design should allow for smooth operation under extreme conditions while minimizing friction between components. It’s also beneficial if the design allows easy access to components for maintenance or replacements, thereby reducing downtime. In all, these considerations contribute to a robust, efficient, and long-lasting performance of slip rings even under the challenging conditions of deep-sea drilling.

Key Challenges and Solutions in Deep Sea Drilling Slip Ring Applications

High Pressure and Temperature

The extraordinary pressures and temperature extremes associated with deep sea drilling present considerable challenges to slip ring application. These conditions can drastically affect the mechanical performance of the slip rings, causing accelerated wear, signal disruptions, and potential operational failure.

Advancements in slip ring technology continue to address these inherent challenges. For instance, the development of high-pressure and high-temperature resistant slip rings utilizes specialized materials and assembly techniques to enhance their durability and reliability. Also, thorough testing methods simulate extreme conditions to verify the performance of these slip rings under high pressure and temperature, ensuring they are well suited for long-term operation in the demanding sea drilling environment.

Signal and Power Transmission

Reliable and stable signal and power transmission are critical for the effective operation of deep sea drilling equipment. However, maintaining this stability in deep sea environments can be complex due to several factors like material corrosion, electromagnetic interference (EMI), and potential mechanical failures.

Advancements in brush technology, such as the use of noble metals, have enhanced the conducting properties of slip rings, reducing signal noise and ensuring consistent power transmission. EMI protection measures, such as shielding and grounding techniques, have been implemented to further reduce signal disruption.

Moreover, the utilization of advanced communication protocols and digital technologies can help in enhancing signal reliability. For instance, the application of fiber optic rotary joints (FORJs) in conjunction with electrical slip rings allows high-speed data transfer with minimal signal losses.

Overall, these techniques and innovations have been fostering stable, reliable signal and power transmission for deep sea drilling slip rings, thereby contributing to the overall performance and efficiency of the drilling operations.

Maintenance and Troubleshooting of Deep Sea Drilling Slip Rings

Preventative Maintenance

Proactive maintenance is integral for ensuring smooth operation and a longer lifespan for deep sea drilling slip rings. Regularly scheduled inspections become essential to monitor and assess the condition of the slip ring and its components. This may include checking for signs of wear or damage to the brushes, monitoring surface conditions of the rings for wear or corrosion, and testing electrical connections for continuity and resistance.

Moreover, to extend the service life of slip rings in challenging marine environments, practices like effective sealing for corrosion protection, correct torque application during assembly, and ensuring that the ring and brush interface is clean and dry, will be beneficial.

It’s always advantageous to follow the manufacturer’s recommendations or guidelines for maintenance, which would detail the specific steps for inspecting and maintaining the slip ring assembly based on its design and application.

Common Issues and Solutions

Even with regular maintenance, potential issues may arise from the rigorous demands of deep sea drilling. These could range from intermittent signal transmission, fluctuation in resistance values, to complete power failure.

For such issues, a systematic troubleshooting approach should be employed. For instance, if the issue is characterized by an intermittent signal, inspecting the ring and brush interface for signs of wear or contamination could be the first step. If the problem stems from a notable increase in resistance values, checking for proper brush alignment or worn-out brushes could be a solution.

Whether to repair or replace a slip ring largely depends on the nature and extent of the problem, as well as cost-effectiveness. Simple issues such as wear or contamination might be fixable with a thorough cleaning or replacement of certain parts (e.g., brushes). However, in a scenario of severe damage or repeated failure, an entire slip ring replacement may be warranted.

It’s crucial to have access to qualified technicians and suitable replacement parts to handle such situations. Companies often offer dedicated support services that can guide through repair or replacement processes, ensuring the slip rings return to their optimal operational condition with minimum downtime.

Conclusion

Slip rings play a pivotal role in the day-to-day operation of deep sea drilling equipment, facilitating the seamless transmission of power and signals amidst the continuous mechanical rotation of various components. They contribute immensely to the efficiency and reliability of drilling rigs, winches, Rotary Steerable Systems (RSS), and Remotely Operated Vehicles (ROVs) in such challenging environments.

Despite the technical challenges posed by high pressure, extreme temperatures, and corrosive conditions of deep sea environments, advancements in slip ring technology are continually improving their performance. Selective material choice for corrosion resistance, adoption of effective sealing solutions, and utilization of high-grade electrical contacts have continuously enhanced the environmental endurance and overall functionality of these devices.

In terms of signal and power transmission, the application of innovative brush technology and effective EMI protection measures have been instrumental, ensuring stable and reliable transmission.

Although regular maintenance is essential to retain the operational efficiency of these slip rings, continued innovations promise to extend their service life and reduce maintenance needs. The emergence of technologies like Fiber Optic Rotary Joints (FORJs) hint at an exciting trajectory for the future of slip ring technology.

As we look to the future, continued research and advancements in material science, digital communication, and superior design practices promise to further elevate slip ring performance. This would eventually contribute to even more efficient and reliable deep sea drilling operations, unlocking new potentials in resource exploration and extraction.

FAQs about Slip Ring Application in Deep Sea Drilling

Q: Why are slip rings crucial in deep sea drilling?

A: Slip rings are a critical component in deep sea drilling due to their functional role in transmitting power and signals between the stationary and rotating parts of the machinery. They ensure seamless operation of drilling rigs and equipment amidst the perpetual mechanical rotation involved in these operations.

Q: What are the challenges faced by slip rings in deep sea environments?

A: Deep sea drilling places immense demands on slip rings, exposing them to high pressure, extreme temperatures, and corrosive conditions presented by the high salt content in seawater. Overcoming these challenges while maintaining reliable power and signal transmission is paramount to the slip ring function in this application.

Q: How do advancements in material and design address these challenges?

A: Constant advancements in slip ring technology help to counter the environmental challenges. Examples include the use of corrosion-resistant materials such as stainless steel and gold alloys that also provide excellent conductivity. Also, the incorporation of effective sealing techniques helps to isolate internal components from the harsh external environment.

Q: How important is it to maintain and regularly inspect slip rings in deep-sea drilling applications?

A: Regular maintenance and inspections are essential for reliable operation of slip rings and elongating their service lifespan. Routine checks can identify signs of wear, corrosion, or other potential issues early on, allowing for necessary repairs or replacements before they escalate to major operational failures.

Q: What does the future hold for slip ring technology in deep sea drilling?

A: Continued research and development promise exciting future trends in slip ring technology. Advancements in material science and digital communication techniques, coupled with superior design practices, aim to enhance slip ring performance and environmental endurance. Some technologies hinting at a promising trajectory include fiber optic rotary joints (FORJs) aiding high-speed data transfer with minimal signal losses.

See What We Can Do