This comprehensive analysis aims to shed light on the essential function of slip rings within measuring instruments. Delve into various kinds of slip rings and their specific applications, gain insights into the benefits they bring to the table, understand the technical problems and corresponding solutions, and envision future trends in this rapidly evolving field.

Introduction to Slip Ring Application in Measuring Instruments

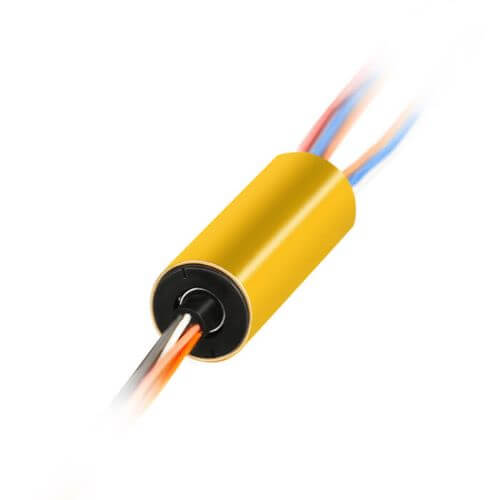

A slip ring, often referred to as a rotary electrical interface, is an electromechanical device that facilitates the transmission of power, signals, or data between stationary and rotating components. With applications spanning a wide range of industries, such as renewable energy, manufacturing, and medical equipment, slip rings have established themselves as essential components in various rotating systems.

In the realm of measuring instruments, the use of slip rings has become increasingly significant owing to the need for devices capable of delivering accurate and reliable measurements. These instruments frequently require continuous rotation and precise signal or data transmission while maintaining a stable power supply. The implementation of slip rings allows for the seamless integration of these components, ensuring the accurate functioning of measuring devices throughout their operation.

The importance of slip rings in measuring instruments goes beyond basic electrical continuity; they contribute to enhanced performance, longevity, and overall system reliability. Due to their inherent flexibility in design, slip rings can be customized to cater to the unique requirements of diverse measuring instruments, ensuring optimal integration and compatibility across systems.

Understanding the role of slip rings within measuring instruments and the various types available is crucial for gaining insights into their benefits and limitations. As technology continues to evolve, so too will the applications of slip rings, further cementing their position as indispensable components in the world of measurements.

The Functionality of Slip Rings in Measuring Instruments

The functionality of slip rings in measuring instruments is extraordinarily broad, and their impact is immense. By establishing an uninterrupted electrical connection between stationary and rotating parts, slip rings contribute significantly to operational efficiency. They ensure that necessary electrical signals, power, or data are seamlessly transmitted, even while components rotate at high speed. The continuous connectivity provided by slip rings is essential for maintaining accuracy and precision in readings — a feature that makes them indispensable to many measuring instruments.

Moreover, the unique design of slip rings minimizes wear and tear caused by friction, reducing maintenance needs and downtime. They also act as a mediator in heat dissipation between moving parts, thereby further preserving the life of the system. Essentially, the incorporation of slip rings enhances overall system efficiency – from device operation to maintenance and longevity.

Taking a closer look at specific measuring instruments helps illustrate the importance of slip rings. In gyroscope systems used for orientation measurements, slip rings are a critical component that ensures constant transmission of power and signals, enabling flawless operation. Meanwhile, in the context of environmental monitoring devices such as wind direction sensors, slip rings facilitate 360-degree rotation while maintaining a consistent data transmission line. Similarly, slip rings form an integral part of high-precision spectrometers, enabling accurate wavelength measurements by ensuring an uninterrupted power supply during constant rotation.

These examples underscore the integral role that slip rings play within various types of measuring instruments. By facilitating uninterrupted connectivity and rotation, they directly contribute to maintaining accuracy, reliability, and operational efficiency.

Types of Slip Rings Used in Measuring Instruments

With a multitude of measuring instruments operating in diverse fields across industries, the requirements for slip rings differ accordingly, leading to the existence of various types. Each type embodies unique features, purpose, and applications – all designed to meet specific operational needs.

One type prominent in the measuring instruments industry is the Capsule Slip Ring. Its miniature design, accompanied by lower torque and compactness, makes it a preferred choice for space-constrained instruments such as pyrometers. Despite the compact silhouette, these slip rings deliver stable signal transmission, making them fit for instruments demanding precision in data handling.

Next is the Through Bore Slip Ring. This design, featuring a large through-hole, is essentially utilized in measuring instruments requiring a free central space for additional integration like cabling, shaft mounting, etc. Commonly found in seismic instruments, these slip rings meet the challenges of integrating other components while maintaining steady data transmission.

The Pancake Slip Ring, with its disc-like design, is used predominantly when length restrictions are more pronounced than diameter limitations. Instruments that require precise axial alignment, such as spectrographs, often utilize pancake slip rings to facilitate streamlined throughput and rotation.

High-Frequency Rotary Joints, sometimes called RF Rotary Joints, are types of slip rings designed for instruments demanding superior signal integrity, capable of handling high frequency, power, and pressure. Radar systems and satellite communication devices often employ these to ensure instant and precise data transmission.

Each of these slip ring types is uniquely crafted to cater to different measuring instruments’ demands, offering efficient solutions to various challenges encountered in rotation-driven data and power transmission. As such, understanding their features, purposes, and applications is paramount when considering the role of slip rings in the measuring instruments’ realm.

Key Advantages of Slip Ring Application in Measuring Instruments

The incorporation of slip rings into measuring instruments provides a plethora of vital advantages. Each of these benefits directly influences the functionality, efficiency, and effectiveness of these devices, contributing significantly to their operational success. Three primary benefits include continuous 360° rotation, accurate and reliable data transmission, and efficient power delivery.

Continuous 360° rotation is one of the most critical advantages provided by slip rings. In many measuring instruments, the need for unrestricted rotation is inherent in their working principle. The capacity of a slip ring to permit this unrestricted rotation ensures that the instrument’s performance is not hampered by any rotation-induced disconnections or interruptions in the signal and power transmission, thereby enhancing the overall reliability and accuracy of these instruments.

Reliable data transmission is another key advantage of slip rings. As the world increasingly leans into digitization, the importance of secure and accurate data transmission has grown exponentially. Slip rings maintain a constant and seamless line of communication between stationary and rotating parts, thereby facilitating uninterrupted data transmission. This feature is particularly important in instruments that rely heavily on real-time data output for their functionality, such as spectrometers or LIDAR systems.

Effective power delivery is also a significant advantage of using slip rings. Instruments often require a dependable source of power to operate optimally. By ensuring a constant power connection even during rotation, slip rings enable measuring instruments to function consistently, regardless of the rotation’s speed or direction.

In summary, the benefits provided by slip rings, such as continuous 360° rotation, reliable data transmission, and effective power delivery, translate into improved accuracy, increased reliability, and enhanced operational efficiency of measuring instruments. The seamless integration of these advantages into the instruments’ design and functionality is a testament to the indispensable role of slip rings in and beyond the realm of measuring devices.

Standard Specifications for Slip Rings in Measuring Instruments

The functionality and reliability of slip rings rest significantly on their adherence to certain standard specifications and ratings. These standards, ranging from performance criteria to safety and material compliances, govern the overall quality, operational integrity, and safety level of slip rings used in measuring instruments.

Performance criteria include specifications like rotational speed, which determines the maximum speed at which a slip ring can operate without affecting its performance. The choice of a suitable rotational speed rating depends on the specific needs of the measuring device. Other important performance criteria encompass electrical parameters like voltage and current ratings, which define the maximum amount of electrical load a slip ring can carry.

Safety standards play a vital role in determining the overall integrity and reliability of slip rings. These include international standards like ISO and IEC, which specify various safety and operational guidelines. Moreover, industry-specific safety standards often govern the use of slip rings in measuring instruments; adhering to these standards is crucial to ensure safety during operation and maintain instrument reliability.

Material compliances, like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), ensure that the materials used in the manufacturing of slip rings are environmentally friendly and safe for use. These also impact factors like durability and resistance to corrosion, which are critical to the slip ring’s lifespan.

Industry standards are also a crucial consideration. For instance, IP (Ingress Protection) ratings determine a slip ring’s resistance against dust and water ingress. A higher IP rating means better protection and is a crucial factor when the measuring instrument operates under harsh or challenging conditions.

Understanding and complying with these standard specifications for slip rings is critical. Adherence to these standards not only ensures optimal performance and reliability but also contributes to the longevity of the measuring instruments, safety during operation, and overall user confidence.

Technical Challenges and Solutions in Slip Rings Applications

The application of slip rings in measuring instruments, while advantageous, is not free from technical challenges. Several common problems, including those related to friction, noise, lifespan, and maintenance needs, can arise. However, with continual advancements in technology, these issues can be effectively managed and overcome.

Friction is a primary concern when slip rings are in operation, largely due to the rotating nature of these components. Excessive friction can lead to wear and tear, disrupting smooth operation and impacting instrument precision. To address this, newer models of slip rings incorporate advanced materials and designs that reduce contact resistance and heat generation, thereby minimizing friction.

Noise is another factor interfering with the performance of measuring instruments. Electrical noise, resulting from the rotating contacts in the slip rings, can interfere with data transmission and reduce overall performance accuracy. To mitigate noise issues, modern slip rings employ advanced shielding techniques and noise minimization strategies, ensuring reliable data transmission without the interference of noise.

With regards to lifespan and maintenance needs, the frequent rotation within slip rings necessitates regular inspection and, eventually, replacement of worn-out parts. However, the advent of contactless slip rings — utilizing magnetic fields or light for signal and power transmission — has revolutionized the scenario. By eliminating physical contact, the wear and tear process along with maintenance needs are significantly reduced, leading to a longer lifespan of the slip ring.

The role of technology in mitigating these challenges cannot be overstated. For instance, the use of fiber optic rotary joints (FORJs) in high-speed data transmission environments has proven to be a game-changer. FORJs, utilizing light for data transmission, are immune to electromagnetic interference and can function seamlessly even in high-speed rotation contexts.

In conclusion, while there are various challenges encountered when applying slip rings to measuring instruments, advancements in materials, design, and technology provide effective solutions, ensuring the continued reliability and efficiency of these critical components.

Case Studies in Slip Ring Applications

Real-world case studies furnish us with a wealth of information and insights into the successful applications of slip rings in measuring instruments and the lessons derived therein.

One prominent example involves the use of slip rings in wind speed measuring instruments used in wind turbines. The constant rotation of turbine blades, coupled with the need for accurate wind speed measurements, posed a unique challenge. The standard slip rings installed initially witnessed high wear rates due to constant rotation and harsh environmental conditions. However, the application of a durable and corrosion-resistant capsule slip ring solved the issue. Not only did the robust construction enhance the lifespan of the ring, but the compact design also facilitated seamless installation. This case underscored the fact that choosing the right slip ring type, considering the operational conditions, significantly enhances instrument durability and reliability.

In another instance, slip rings ran into noise issues in seismic measuring instruments. The minute tremor signals were getting disturbed by the electrical noise from the slip rings. The solution came in the form of fiber optic rotary joints (FORJs). By using light instead of electrical signals for data transmission, the FORJs successfully eliminated the interference, leading to accurate seismic readings. This case underscores the role of technological advancements in overcoming challenges inherent in slip ring applications.

A third case involves high-frequency medical imaging devices, where traditional slip rings couldn’t maintain the quality of data transmission due to the high-frequency requirements. Herein, RF (Radio Frequency) rotary joints provided a breakthrough. The RF rotary joints’ capacity to endure high-frequency data transmission without signal loss ensured high-quality imaging and improved diagnostic accuracy. This scenario harshly highlights how customization, in terms of slip ring type selection, contributes significantly to operational efficiency.

These case studies elucidate the core lesson – the importance of understanding the specific requirements and challenges of the measuring instrument and picking a suitable slip ring or its advanced alternatives. By doing so, it’s entirely plausible to enhance the device’s performance while ensuring the ring’s longevity.

Future Trends and Opportunities in Slip Ring Applications

As technology evolves and industries advance, the application of slip rings in measuring instruments continues to adapt to meet new challenges. By analyzing potential trends and looking ahead, we can predict new opportunities and growth directions in the field of slip rings and measuring instruments.

- Contactless Technology: One future trend is the increasing adoption of contactless slip rings and alternative methods for data and power transmission. Technologies such as capacitive, inductive, and optical slip rings not only minimize friction and wear and tear but also reduce maintenance requirements while enhancing lifespan and operational efficiency. Such advancements are bound to find key applications in new smart features and IoT applications.

- Miniaturization: Another trend lies in the miniaturization of slip ring components to accommodate more compact measuring instruments. The demand for smaller, more intricate slip rings that can operate alongside other critical components without impeding performance or taking up valuable space will continue to rise. This trend poses an exciting opportunity for the development of new slip ring solutions with optimized packaging and form factors.

- Integration of Advanced Materials: As improvements in material sciences occur, we can expect an increasing focus on the utilization of advanced materials in the construction of slip rings. Improved materials that reduce friction, optimize heat dissipation, and resist corrosion will play a vital role in enhancing the reliability and lifespan of slip rings, extending their serviceability even in harsh environments.

- Smart Monitoring and Predictive Maintenance: In an era of Industry 4.0 and IoT interconnectivity, intelligent systems will increasingly characterize slip rings. Self-monitoring features, such as temperature sensing and condition monitoring, will become commonplace, allowing for a more proactive approach to maintenance and fault prediction. This will not only increase the operational efficiency of measuring instruments but also reduce downtime and improve overall productivity.

- Customizable Solutions: As measuring instruments diversify and their unique requirements expand, there will be an increased demand for customizable slip ring solutions tailored to specific needs. Custom designs that cater to the particular demands of a device, such as specialized connectors, unique configurations, or advanced signal transmission capabilities, will become increasingly vital to addressing individual applications.

In conclusion, the future of slip rings in measuring instruments is one of fast-paced innovation, spurred by technological advancements and an increasingly interconnected world. We can anticipate a growing emphasis on customization, advanced materials, miniaturization, and smart features, presenting numerous opportunities to optimize the application of slip rings and expand their role within the instrumentation field.

Conclusion

In conclusion, slip rings play a pivotal role in enabling efficient and reliable measurements in a multitude of instruments. As technological advancements continue to influence their design and functionality, their potential applications and benefits promise to increase even further. Indeed, slip rings stand as a testament to how a seemingly small component can, quite literally, keep the world of measurements turning.

See What We Can Do