In the realm of technological systems where precision and reliability are non-negotiable, the photoelectric pod stands out as a paragon of innovation. Photoelectric pods are advanced electro-optical systems that integrate cameras, lasers, and other sensory equipment. They are pivotal in a plethora of applications that demand high-precision observation and tracking from a distance.

Slip Ring Application in Photoelectric Pod

In the military sector, these pods are the eyes in the sky, mounted on aircraft and drones, providing critical data for reconnaissance, surveillance, and target acquisition. The intelligence gathered through the pods is invaluable for national security and defense, making their reliability a matter of paramount importance. The weather monitoring industry also heavily relies on photoelectric pods, utilizing their capabilities to observe and predict meteorological phenomena, ultimately helping to save lives by enabling advanced warnings and facilitating disaster readiness. Moreover, in remote sensing applications, photoelectric pods aid in acquiring data about the Earth’s surface, which is essential for environmental monitoring, resource management, and city planning.

At the heart of these sophisticated pods lies the slip ring—an unpretentious yet ingenious device that is fundamental to the pod’s optimal functionality. This electromechanical apparatus enables the transmission of power and electrical signals through a rotating interface. Its seamless operation is vital, primarily because the pods must rotate endlessly to maximize their field of view without any hindrance in data or power transfer.

The significance of slip rings in this context cannot be overstated; they are the linchpins that enable the flawless rotation of the sensors while sustaining a constant stream of high-fidelity data. A slip ring can maintain electrical continuity without compromising the structural integrity or performance of the rotating pod that is so crucial. The reliability of slip rings guarantees that the critical missions these pods undertake aren’t jeopardized by the mere mechanical limitations of rotating components.

Not only does the functionality of photoelectric pods hinge on the slip ring’s quality and performance, but so too does the safety and efficacy of the operations they support. In essence, while the pod serves as the gathering hand of vital data, it is the slip ring that ensures this hand can always turn, reach, and function without restraint. Thus, understanding and refining slip ring technology becomes a keystone in leveraging the full potential of photoelectric pods across various fields.

Working Principle of Photoelectric Pod

To fully comprehend the critical role of slip rings in photoelectric pods, we must first delve into the inner workings of the pod itself. Photoelectric pods primarily operate by capturing and processing electromagnetic radiation to yield valuable information. These versatile systems are equipped with an array of sensors, including visible and infrared cameras, as well as laser rangefinders and designators. Each sensor possesses unique capabilities, and in tandem, they yield a holistic view of the environment.

At the core of a photoelectric pod’s design is the gimbal—a mechanical structure that allows for the precise and unhindered movement of the pod’s various sensors. This ensures that the pod can effortlessly track targets or maintain a stable field of view, even during motion. For instance, when mounted on an unmanned aerial vehicle (UAV) or helicopter, the photoelectric pod could encounter mechanical vibrations, turbulence, and rapid changes in direction. The gimbal’s stabilization and the ability to rotate along multiple axes enable a constant and steady view despite these external perturbations.

Role of Slip Rings in Photoelectric Pods

Within the complex mesh of gimbal mechanics and electronic sensor components, slip rings take on a pivotal role. As the gimbal rotates along its axes, the challenge of continuous power supply and signal transfer arises. The slip ring’s primary function is to bridge the rotating and stationary parts of the pod, thus facilitating an ongoing flow of electrical current and allowing for the smooth transmission of data between them.

Slip rings comprise two main components: the brushes and the rings. The brushes typically consist of metal or graphite and maintain contact with the rings, which conduct the electrical current. As the gimbal rotates, these brushes slide over the surface of the rings, ensuring uninterrupted connectivity. This enables the pod’s various sensors to remain powered and maintain communication with the rest of the system at all times.

The importance of slip rings in photoelectric pods stems from the need for stable and continuous transmission of data and power as the pod rotates. Without the slip ring’s ability to maintain a seamless connection during rotation, the pod’s performance would be severely hampered. It would jeopardize the capability of the pod to track objects or scan the environment, rendering it unreliable for crucial applications in military, weather monitoring, and remote sensing operations.

In summary, the working principle of a photoelectric pod relies heavily on the coordinated operation of its sensors and gimbal mechanics. However, the critical link that holds these components together and allows them to function harmoniously is the slip ring. By understanding the underlying principles of slip ring operation and optimizing their performance in a photoelectric pod context, we can unlock the full potential of these extraordinary systems.

Types of Slip Rings Used in Photoelectric Pods

Choosing the right type of slip ring plays an integral role in maximizing the efficiency and reliability of photoelectric pods. There are several types of slip rings in the market, each offering unique advantages and trade-offs. The four main types of slip rings commonly used in photoelectric pods include contact slip rings, contactless slip rings, fiber optic rotary joints (FORJs), and pancake slip rings.

Contact Slip Rings

Contact slip rings, also referred to as sliding contact slip rings, are the most common type of slip ring. They consist of conducting rings with brushes resting against them. As the slip ring rotates, electrical signals and power are transferred between the stationary brushes and rotating rings. They are known for their simplicity, low cost, and flexibility in terms of the number of circuits they can accommodate.

Contactless Slip Rings

Contactless slip rings, or wireless slip rings, use magnetic or electromagnetic induction to transfer data and power between the stationary and rotating parts. Since there’s no physical contact, these slip rings reduce wear and tear, minimize noise, and offer a longer service life. However, they may be more complex to design and are generally less efficient and more expensive than contact slip rings.

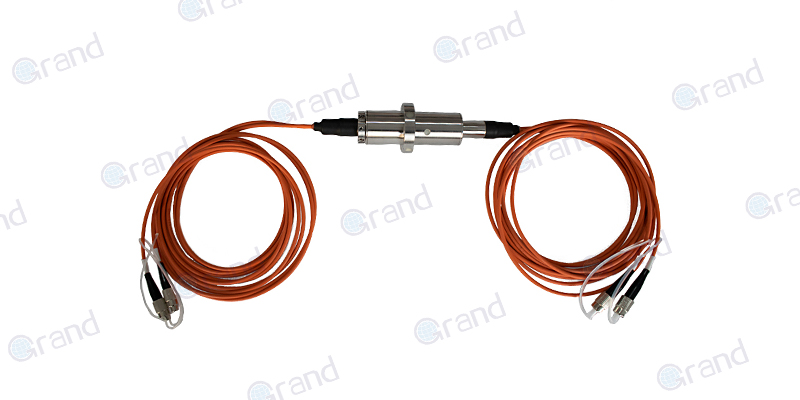

Fiber Optic Rotary Joints (FORJs)

FORJs form a category of their own as they transfer optical signals rather than electrical signals. These devices are ideal for transmitting large amounts of data over long distances with minimal loss. The absence of electromagnetic interference makes them suitable for applications where high speed, high data rate, and precise transmission are a priority. However, FORJ’s complexity and cost make them a selective choice, often opted for only in high-end applications.

Pancake Slip Rings

Pancake slip rings bear their name due to their flat disc-like design where the concentric conductive rings are positioned on a flat plane instead of a cylindrical structure. This design is favorable when length is a constraint and it allows for low-height axial installation. However, compromises are made with the increased diameter and potentially lesser performance due to shorter brush lifetimes and higher electrical noise.

The decision to use a particular type of slip ring depends largely on the specific operational requirements. For cost-effective solutions with minimal complexity, contact slip rings may be the preferred choice. Still, where durability and reliability are paramount despite an expense escalation, contactless slip rings or FORJs may be applicable. Meanwhile, in compact installations with height limitations, pancake slip rings may prove to be a viable option.

In conclusion, understanding these slip ring types, their strengths, limitations, and ideal applications, helps in making an informed choice. This choice, in turn, will influence the performance, durability, and overall success of the photoelectric pod’s missions.

Selection Criteria for Slip Rings in Photoelectric Pods

The successful operation of a photoelectric pod relies heavily on the correct selection of a slip ring, tailored to its specific application and operating conditions. Such decisions involve careful consideration of various factors, including but not limited to rotational speed, data transmission rates, environmental conditions, the number of channels, power, signal characteristics, and expected working life.

Rotational Speed

The speed at which the slip ring will have to continuously operate is a key determinant in its selection. Higher rotational speeds might require specific slip rings designed to maintain electrical continuity at such speeds without significant friction or wear which can reduce lifespan and increase maintenance requirements.

Data Transmission Rates

Different photoelectric pod applications may require different volumes of data to be transmitted. For instance, a pod used for high-resolution terrain mapping would need to transmit a larger volume of data compared to a thermal imaging pod used for heat signature detection. Hence, the slip ring’s capacity to transmit data at higher rates without loss or interruption becomes an essential selection criterion.

Environmental Conditions

Photoelectric pods are often employed in extreme environmental conditions. From high-altitude chilly wind gusts in reconnaissance missions to the heat and dust in desert-based surveillance, slip rings must withstand a wide range of temperatures, humidity, dust, and vibrations while maintaining performance. Special slip rings may be needed for particularly harsh environments, including environment-sealed or even explosion-proof designs.

Number of Channels

In a photoelectric pod, numerous sensors may be working simultaneously, each requiring power and a pathway to transmit data. Thus, the number of separate circuits – or channels – that a slip ring can handle influences both its selection and design, as this affects the pod’s comprehensive multi-sensor functionality.

Power and Signal Characteristics

The electrical power requirement of the sensors in the pod and the nature of the signals that have to be transmitted—whether digital or analog, noisy or sensitive—compels a close examination of the slip ring’s electrical specifications. The slip ring must be capable of delivering the requisite power for all sensors while ensuring that signal integrity is preserved.

Working Life

The expected working life of the slip ring under its operational conditions directly impacts maintenance schedules and the total cost of operations. An extended lifespan may justify a higher initial investment in a slip ring that offers a reduced wear design or contactless operation.

By scrutinizing these factors, we ensure the selected slip ring will reliably match the demands of the photoelectric pod, thus optimizing the system’s overall performance and durability. The choice of a slip ring is a balanced optimization where specific requirements define the selection parameters, and ultimately, the success of photoelectric pods in their diverse yet crucial applications.

Slip Ring Application in Photoelectric Pod: Case Studies

In understanding the significance and practical implications of slip rings in photoelectric pod applications, examining real-world case studies provides valuable insight into their performance and benefits in diverse scenarios. The following examples emphasize the importance of selecting the right slip ring to optimize the functioning of photoelectric pods.

Case Study 1: Military Unmanned Aerial Vehicle (UAV)

In a military operation requiring surveillance of a potential conflict zone, a UAV equipped with a photoelectric pod was deployed. This pod consisted of high-resolution visible and thermal imaging cameras, as well as a laser rangefinder and designator. With high data transmission rate requirements and extreme environmental conditions, a fiber optic rotary joint (FORJ) coupled with a contactless slip ring was selected. These devices ensured undisrupted, noise-free data transmission and offered increased durability with lower maintenance needs, ultimately resulting in a successful reconnaissance mission.

Case Study 2: Forest Fire Monitoring System

A forest management agency employed helicopters fitted with photoelectric pods for real-time monitoring and analysis of forest fires. These pods used thermal and visible imaging cameras to detect heat signatures and track fire propagation. Given the harsh, smoke-filled environment and the high rotational speed requirements, contactless slip rings were chosen for their minimal wear and improved reliability. The system performed consistently in tracking the rapid spread of fires, providing invaluable data to teams on the ground and aiding in firefighting efforts.

Case Study 3: Wildlife Research

Researchers studying migratory patterns and behavior of wildlife used a small unmanned aerial vehicle (UAV) fitted with a photoelectric pod containing infrared and visible cameras. Due to the compact nature of the UAV and tight installation space constraints, a pancake slip ring was selected. Despite the reduced axial length, the pancake slip ring facilitated the smooth transfer of power and data for the cameras, enabling the UAV to track animals with precision, and contributing to valuable insights for wildlife research and conservation efforts.

Case Study 4: Meteorological Balloon-borne Observation System

Weather research institutes often utilize meteorological balloons equipped with photoelectric pods, featuring advanced sensors for atmospheric data collection. With varying temperatures and humidity at different altitudes, the environmental conditions necessitated a tailored slip ring solution. An environment-sealed contact slip ring, capable of operating over a broad temperature range, was employed to ensure steady power supply and data transmission. Consequently, researchers acquired critical weather data crucial to meteorological and climate studies as well as real-time weather forecasting.

These case studies demonstrate how the right choice of slip rings for varying photoelectric pod applications can profoundly impact the overall system’s performance, durability, and effectiveness. By meticulously considering the operational requirements and environmental factors, and selecting appropriate slip ring solutions, we can unlock the full potential of photoelectric pods in diverse and vital applications.

Slip Ring Application in Photoelectric Pod: Challenges and Solutions

Achieving a reliable and efficient operation of photoelectric pods requires overcoming several challenges associated with the application of slip rings. These issues largely involve wear and tear, signal noise and interference, and environmental resistance. Thanks to technological advances and innovative solutions, many of these challenges can be effectively addressed.

Wear and Tear

A prevalent concern in the usage of slip rings is their durability due to continuous physical contact in most types. This results in wear and tear, leading to reduced reliability over time, increased maintenance frequency, and potentially, failures and interruptions in the field. To address this, there’s a growing trend towards contactless slip rings, such as wireless or inductive types. They eliminate physical contact, thereby drastically reducing wear and increasing life expectancy, albeit at a higher cost.

A promising trend in traditional contact slip rings is the development of advanced materials for brushes and rings, designed to withstand more rotations, reduce noise, and improve overall performance. Various alloys, precious metals, and graphite compounds are now in use, each with their unique benefits and trade-offs.

Transmission Noise

Signal and power transmission noise and interference can be a significant issue, especially in high-data-rate applications or sensitive signal transmissions. Such noise can be minimized by using slip rings with superior shielding and grounding methods. Opt for fiber optic rotary joints (FORJs) can also be a viable solution as they transmit signals in the form of light waves, thus remaining unaffected by electromagnetic interference.

Challenges in Harsh Environments

Slip rings designed to operate in harsh environments pose another challenge. Extreme temperatures, dust, moisture, and corrosive environments are some conditions that can affect their performance. Various measures, such as sealed designs, corrosion-resistant materials, and special bearings and lubricants, are implemented to meet these requirements.

Smart Monitoring

In addition to these advances, the incorporation of smart monitoring systems represents an innovative solution to these issues. These systems can provide early warnings of slip ring wear or critical failures, enabling preemptive maintenance and minimizing downtime.

Adoption of Wireless Technology

With the rapid evolution of wireless technology, the prospect of wireless power transmission and data sharing has opened up, bringing forth a new paradigm in slip ring technology. Although still at a nascent stage and saddled with limitations, this technology may, in the long run, offer an ultimate solution to many slip ring challenges.

In conclusion, technological advancements and innovative designs provide a range of solutions to various challenges faced in the application of slip rings in photoelectric pods. Continual research and development in this field, coupled with a deep understanding of the operational requirements, will continue to revolutionize the reliability, efficiency, and effectiveness of photoelectric pods in their myriad applications.

Slip Ring Application in Photoelectric Pod: Future Trends

The role and functionality of slip rings in photoelectric pods are beginning to evolve as technology pushes the boundaries of what’s possible. With the advent of the Internet of Things (IoT), Artificial Intelligence (AI), and ever-advancing material sciences, predictions for future trends in slip ring technology suggest a leap toward smarter, more durable, and more efficient designs.

Miniaturization

As photoelectric pods become increasingly compact and sophisticated, so too must slip rings follow the trend towards miniaturization. This necessitates the design of smaller slip rings, which despite their reduced size, must continue to deliver on high-speed data transfer and power transmission. Such developments could lead to the rise of micro slip rings, purpose-built for the next generation of miniaturized photoelectric pods.

Intelligent Slip Rings

With the integration of IoT and AI into virtually every technology, it’s foreseeable that ‘intelligent’ slip rings will become more common. These smart slip rings may feature embedded sensors for real-time monitoring of parameters such as wear, temperature, and electrical performance. IoT connectivity provides the capability of remote performance monitoring, predicting maintenance needs, and enabling preemptive action. Furthermore, AI algorithms can help optimize performance, extend lifespan, and improve reliability by analyzing the collected data and making autonomous adjustments.

Contactless Designs

Further developments in contactless slip ring technology are anticipated. Contactless or wireless slip ring function helps eliminate issues of wear and tear and related maintenance costs. The future could see greater reliability and operating lifetimes for these designs, enhanced data transfer rates, and even new contactless designs capable of overcoming current power delivery limitations.

High-Performance Materials

Continued advancements in material science are expected to revolutionize the construction of slip rings. New conductive materials with reduced friction, increased durability, and noise reduction capabilities could fundamentally improve the traditional design parameters for slip rings. Additionally, the development of environmentally-resistant materials will enhance their durability and performance in harsh conditions.

Wireless Power Transmission

The concept of wireless power transmission, although currently in its infancy, shows promise as a future trend applicable to slip rings. This technology could fundamentally alter the design requirements and operational efficiency of photoelectric pods, enabling completely contactless energy sharing and data transfer.

While predicting future trends always carries a degree of uncertainty, the evolution of slip ring technology will continue to be driven by broader technological advances. As these technologies mature and new ones emerge, they will undoubtedly pave the way for unprecedented enhancements in the performance, efficiency, and applications of photoelectric pods.

Conclusion

In conclusion, slip rings play a central role in the functionality of photoelectric pods. It’s the meticulous selection and adequate application of these components that ensure the optimal operation of these systems, with a promising future brimming with technological advancements inspiring optimism for the times ahead.

FAQs about the Slip Ring Application in Photoelectric Pod

To deepen our understanding of slip ring applications in photoelectric pods, it’s beneficial to address common queries and misconceptions. Below are some frequently asked questions about this topic, along with detailed answers.

Q1: What is the purpose of a slip ring in a photoelectric pod?

A: The primary purpose of a slip ring in a photoelectric pod is to facilitate uninterrupted power supply and data transmission between rotating and stationary parts. This ensures the smooth operation of different components like cameras or sensors installed within the pod, despite the continuous rotation.

Q2: Are contactless slip rings always a better choice than contact types?

A: Contactless slip rings do have advantages, including minimal wear and tear and low transmission noise. However, they are often more expensive and may have power delivery limitations. Therefore, the choice between contact and contactless slip rings depends on specific application requirements, such as budget, expected lifecycle, data rate, and environmental conditions.

Q3: Can slip rings operate in all kinds of environmental conditions?

A: While slip rings are designed to operate in a variety of environments, extreme conditions such as high/low temperatures, moisture, corrosive atmospheres, or high dust levels can affect their performance and life expectancy. Specialized designs, such as sealed or corrosion-resistant slip rings, are available for such challenging conditions.

Q4: Will the advent of wireless technologies eliminate the need for slip rings?

A: While wireless technologies have enormous potential, they currently come with limitations, particularly in terms of power transmission and range. Furthermore, certain application environments may not be suitable for wireless connections. Hence, while wireless technology may reduce some needs for slip rings, it will not eliminate them in the foreseeable future.

Q5: How does the integration of IoT and AI affect slip ring applications in photoelectric pods?

A: IoT and AI integration can transform traditional slip rings into “smart” slip rings. With embedded sensors and connectivity, these devices can monitor operational parameters in real-time, predict maintenance needs, and optimize performance. This not only enhances the life expectancy and reliability of slip rings but also facilitates an overall improved performance of photoelectric pods.

Q6: Are there alternatives to slip rings for applications in photoelectric pods?

A: Although slip rings are the most common solution for power and data transmission between rotating and stationary parts in photoelectric pods, there are alternative solutions such as swivel joints and twist capsules. However, these may not satisfy the performance demands of high-speed or high-data-rate applications as effectively as slip rings.

See What We Can Do