Slip Ring Applications for Digital Data Transmission refers to the usage of slip rings or rotary electrical connectors in the transmission of digital data. These devices are essential components that enable the movement of electric signals and power from stationary to rotating structures. A conductive ring and brush assembly, which is usually positioned at the device’s center, is rotated, maintaining an uninterrupted electrical connection throughout.

In the digital data transmission sector, slip rings hold a pivotal position. Their ability to provide a dependable and streamlined method to transfer power and data over a rotating interface offers a significant technological edge. This is especially the case in applications demanding constant rotation, like wind turbines and medical imaging equipment, among others.

The Role of Slip Rings in Data Transmission

What are Slip Rings?

Slip rings are electromechanical devices designed to transmit electrical signals, power, or data between a stationary structure and a continuously rotating component. These devices consist of a rotating assembly integrated within a stationary housing, including conductive rings and brushes that maintain a continuous electrical connection even during rotation. This ability to transfer electrical signals and data without disrupting the spinning motion makes slip rings a vital component in numerous applications.

The Basics of Their Function and Design

The fundamental design of a slip ring comprises two primary components: the rotating assembly (which is sometimes called the rotor) and the stationary brushes (also known as stators). The rotor features concentric rings made of conductive material, typically separated by insulating layers to prevent cross-connections. Each ring is connected to an individual signal or power line.

Corresponding to each conductive ring is a brush made of graphite or precious metal alloys – materials chosen for their low electrical resistance and minimal wear properties. These brushes are held against the rings with slight pressure, ensuring contact even during high-speed rotation. As the rotor turns, the brushes maintain an electrical connection with their respective rings, enabling the transfer of electrical signals, data, or power from the stationary structure to the rotating component, or vice versa.

Explanation of How Slip Rings Contribute to Digital Data Transmission

In the context of digital data transmission, slip rings play a pivotal role in enabling seamless, high-speed communication across a variety of applications. As devices become more complex and data-driven, the ability to transmit digital signals and data while maintaining continuous rotation is crucial to ensuring the optimal performance of numerous systems.

To illustrate this more explicitly, consider a high-resolution security camera that needs to rotate 360 degrees without interruption. Without slip rings, wiring would become entangled, severely limiting the camera’s range or operational capacity. By using slip rings, the camera can transmit live video data to the stationary control system with ease and without any hindrance from the rotation.

In summary, the role of slip rings in digital data transmission is to provide an efficient and reliable means of transferring data across rotating interfaces. This technology has proven invaluable for many industries, ranging from aerospace and healthcare to renewable energy and telecommunications, by enabling more advanced, data-driven devices to perform consistently even during continuous operation.

Different Types of Slip Rings for Data Transmission

Slip rings are not a one-size-fits-all solution, and as such, they come in various designs and types to cater to different systems’ specific requirements. While the core function of transmitting data or electric signals between stationary and rotating parts remains constant, the type of slip ring used can significantly affect the efficiency, speed, and reliability of the transmission. This section illuminates various types of slip rings and provides insights into their specific uses in different scenarios.

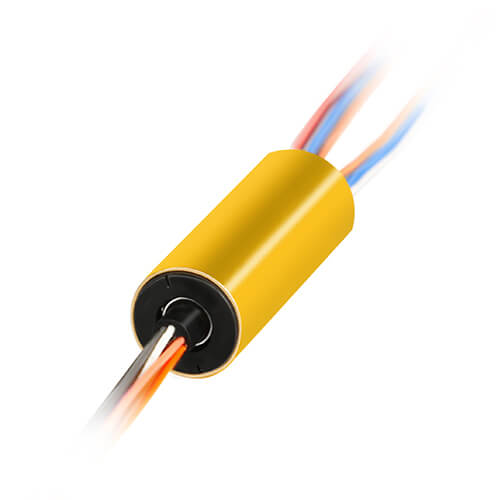

Capsule Slip Rings

Capsule slip rings, small in size and usually cylindrical, are often well-suited for implementing into systems with space constraints. Despite their compact design, they effectively transmit power and high-speed data concurrently for low-speed systems. These miniature slip rings are commonly used in devices such as CCTV cameras and medical equipment, where equipment compactness is crucial without compromising on the transmission quality.

Through-Bore Slip Rings

Through-bore slip rings are named after their defining characteristic: a central hole or “bore” that can accommodate other components such as pneumatic or hydraulic lines, shafts, or other cabling. The through-bore design offers flexibility in managing a wide range of data, power, and signal transmissions, lending themselves well to industrial applications. With high adaptability for high-speed data transfers, through-bore slip rings are often employed in heavy machinery, robotics, and wind turbines.

Pancake Slip Rings

Pancake slip rings, characterized by their flat, disc-like shape, are typically preferred when length or height restrictions pose challenges. They provide similar functionality as other types of slip rings but in a compact, flat package. While they may suffer from increased electrical noise due to their flat design, advancements in modern designs have largely mitigated these issues. Pancake slip rings find extensive usage in applications where height is a restraint, such as turntables and radar antennae.

In brief, while all slip rings serve the fundamental purpose of transmitting electrical signals or data amidst rotation, the specifics of their design offer different advantages serving a multitude of applications. One must carefully choose the type, based on the system requirements and the special attributes each variation provides, to ensure seamless and efficient digital data transmission.

In-depth Analysis: Slip Ring Performance

The performance of slip rings in digital data transmission is critical to minimizing errors, interference, and potential downtime. Multiple factors influence slip ring performance, particularly in data transmission, emphasizing the importance of understanding these components when selecting the appropriate slip ring for a specific application.

Factors that Influence Slip Ring Performance in Data Transmission

- Contact Material: The choice of material for the brushes and rings significantly impacts the slip ring’s performance. Materials with low electrical resistance and minimal wear properties are essential to ensure long-lasting and reliable connections. Precious metal alloys are often used for their excellent electrical conductivity and low friction, which contributes to maintaining adequate data transmission quality.

- Number of Rings and Brushes: The quantity of rings and brushes of a slip ring directly correlates to the amount of data and power that can be transmitted. To support multiple channels or transmit more complex data simultaneously, it’s essential to choose a slip ring design with an appropriate number of rings and brushes.

- Encapsulation and Sealing: Slip ring performance is also determined by the choice of encapsulation and sealing. Well-encapsulated and sealed units provide better protection against environmental factors, such as dust, humidity, and extreme temperatures, ensuring long-lasting and stable data transmission.

- Signal Quality: Maintaining a high signal-to-noise ratio is essential in digital data transmission. High levels of electrical noise can distort the data and cause errors during transmission. Factors such as brush contact reliability and material choice contribute to the overall signal quality that a slip ring can provide.

The Relation of Slip Ring Design to Data Transmission Quality

The design of a slip ring has a profound impact on data transmission quality. In essence, a well-designed slip ring not only minimizes wear and tear but also preserves optimal signal quality and ensures the reliable exchange of data or power between stationary and rotating structures.

Various design aspects play a role in determining data transmission quality:

- Geometry: The geometry of the slip ring, comprising the concentric arrangement of rings and brushes, can affect electrical noise. A properly designed slip ring will minimize crosstalk or interference from neighboring channels, ensuring clean data transmission.

- Material Compatibility: The compatibility between materials of contact surfaces (brushes and rings) is essential. Using materials that are incompatible can lead to increased friction, wear, and noise, ultimately affecting data transmission quality.

- Brush Pressure: The pressure exerted by brushes on the contact rings plays a significant role in determining the stability and reliability of the connection. Insufficient brush pressure can lead to intermittent connections and signal loss, while excessive pressure can result in accelerated wear and tear, negatively impacting overall transmission quality.

- Integration with Other Components: In many applications, slip rings need to be integrated with other components, such as optical fiber rotary joints or fluid rotary unions. The seamless integration of these components in slip ring designs is crucial for high-quality data transmission.

In conclusion, both the design and choice of material play critical roles in determining the performance of slip rings in digital data transmission. Understanding these factors and their impact on data transmission quality is pivotal for selecting suitable slip rings, ensuring that they meet the requirements of various applications and promote seamless, reliable data transmission.

Case Studies and Application Examples of Slip Rings for Data Transmission

To offer a more practical understanding of how slip rings contribute to digital data transmission, let’s look at some application examples. From security systems to medical devices, slip rings play an essential role in various industries, bringing life to numerous solutions and innovations.

Security Surveillance Systems

High-resolution security camera systems often require continuous 360-degree rotating motion while transmitting high-definition video to the receiving station. In this scenario, slip rings enable seamless video data transmission from the rotating camera to the stationary control system, providing uninterrupted surveillance. This manifestation of slip rings empowers the camera to rotate endlessly without twisting or damaging the wires, thereby facilitating constant, real-time monitoring without compromising on the video quality.

Medical Imaging Devices

Medical imaging devices, such as CT scanners or MRI machines, require slip rings to transmit patient data continuously during the scanning process. The imaging system needs to rotate around the patient to capture different angles, necessitating continuous power and signal transmission. For these devices, high-performance slip rings enhance the quality of medical diagnoses by ensuring uninterrupted, high-speed, and error-free data transmission.

Wind Energy Generation

In wind turbines, slip rings ensure the transfer of data from the rotating blades to the stationary control system, even amidst fierce wind gusts. Wind speed and direction, blade angle, and other key operational data are continually being transmitted, allowing for real-time monitoring and adjustments for optimal efficiency. This data is crucial for maintaining the correct operation of the turbine and minimizing wear and tear. Through-bore slip rings are often used in wind turbines to handle power, signal transmission, and the entry passage for hydraulic or pneumatic lines used for blade pitch control.

Satellite Equipment

In satellite communications, the ground-based antenna usually rotates to maintain alignment with the satellite. During the antenna tracking operation, slip rings are used to transfer signals and power between the spinning antenna and the stationary base station. Capsule slip rings with low electrical noise are the preferred choice in this application due to the criticality of signal clarity in telecommunications.

In conclusion, slip rings play a vital role in ensuring seamless data transmission in various fields. These case studies provide a glimpse into how slip rings have become an integral part of many technological applications, ensuring smooth operation and accurate, real-time data transmission in complex moving systems. Their implementation in different sectors demonstrates the broad scope and adaptability of these pivotal components.

Future Trends of Slip Rings for Data Transmission

The world of slip ring technology is continuously evolving, driven by advancements in materials, design, and manufacturing. As the demand for seamless and efficient data transmission increases across various industries, slip ring technologies continue to adapt, leading to new developments in the field. In this section, we will discuss the latest trends and future prospects in the slip ring market.

Miniaturization

As technology becomes more compact, there is an emerging need for slip rings to accommodate this trend as well. The miniaturization of slip rings is prominently seen in applications such as medical devices and robotics, where space constraints are key considerations. Developments in material science and manufacturing techniques are enabling slip ring manufacturers to produce even smaller and lighter slip rings without sacrificing transmission efficiency or reliability.

Increased Data Transmission Rates

The demand for higher data transmission rates is growing rapidly in various fields such as telecommunications, smart manufacturing, and autonomous vehicles. This expansion necessitates innovations in slip ring technologies to manage these increased data rates without sacrificing quality or signal integrity. Advancements in contact materials, high-speed signal transmission techniques, and improved shielding are expected to contribute to the development of slip rings that can cope with the demand for increased data transmission rates.

Wireless Slip Rings

A growing number of devices and systems are making the transition to wireless technology, leading to the development of wireless slip rings, also known as rotary transformers. These devices use inductive or capacitive coupling to transmit data or power wirelessly between the stationary and rotating parts, removing the need for physical brushes and rings, which in turn reduces wear and maintenance. Although still relatively new, this technology is expected to gain traction in the future, particularly in high-precision or low-maintenance applications.

Integration with IoT and Industry 4.0

With the emergence of Industry 4.0 and the Internet of Things (IoT), there is a growing need for slip rings that can seamlessly integrate with these new technologies. Advanced slip rings capable of transmitting both data and power through a single device offer exciting possibilities for automation, predictive maintenance, and remote monitoring. This new generation of slip rings is expected to provide even greater efficiency and ease of deployment in various industrial applications.

Eco-friendly Materials and Processes

As the focus on sustainability increases globally, slip ring manufacturers are exploring eco-friendly materials and production processes. The development of environmentally friendly materials with low friction and excellent conductivity may help reduce energy consumption and waste in various applications. Additionally, the incorporation of green manufacturing practices in the production of slip rings is expected to minimize environmental impact.

In conclusion, the slip ring industry is expected to witness significant changes in the coming years due to rapid advancements in technology and growing demands from various sectors. These future trends, which include miniaturization, increased data transmission rates, wireless slip rings, integration with IoT and Industry 4.0, and the use of eco-friendly materials, emphasize the potential for improved efficiency, performance, and sustainability in the world of slip rings.

Conclusion

To recap, slip rings are essential components in digital data transmission systems, enabling the reliable transfer of power and signals between stationary and rotating parts. Throughout this discussion, we have examined various factors influencing slip ring performance, such as contact materials, the number of rings and brushes, encapsulation, and signal quality. We also delved into the importance of slip ring design in terms of data transmission quality, highlighting essential design aspects like geometry, material compatibility, brush pressure, and integration with other components.

Illustrating the practical applications of slip rings, we explored real-world examples in diverse industries, such as security surveillance systems, medical imaging devices, wind energy generation, and satellite equipment. These case studies demonstrate the indispensable contribution of slip rings to the seamless operation of numerous devices and systems worldwide.

In anticipation of the future, we investigated the latest developments and trends in the slip ring industry, including miniaturization, increased data transmission rates, wireless slip rings, integration with IoT and Industry 4.0, and the use of eco-friendly materials. These advancements promise growth and improvements in slip ring technology, ensuring that it will continue adapting to meet evolving demands from various sectors.

In conclusion, the field of slip rings is dynamic, continuously evolving to cater to the growing needs of our fast-paced, technologically-driven world. As the demand for seamless and efficient data transmission continues to increase, so too will slip ring technologies rise to the occasion, enhancing our ability to connect, communicate, and innovate in countless applications.

FAQs about Slip Rings for Data Transmission

In this section, we aim to address some of the most common questions about slip ring applications for digital data transmission to further clarify their usage, capabilities, and potential development.

Q: How do slip rings ensure high-speed data transmission?

A: Slip rings ensure high-speed data transmission by minimizing contact resistance and reducing electrical noise to maintain a high signal-to-noise ratio. Materials with low electrical resistance and minimal wear, such as precious metal alloys, are used. Also, intricate designs aim to minimize crosstalk and interference, ensuring clean data transmission.

Q: What types of data can be transmitted through a slip ring?

A: Slip rings can transmit analog and digital data, including but not limited to video, audio, and control signals. They can also transmit power simultaneously with the data signals. The type and amount of data that a slip ring can handle depend on its design and the number of rings and brushes it includes.

Q: Can slip rings work in extreme environmental conditions?

A: Yes, slip rings are designed to work in a variety of harsh environmental conditions, ranging from high temperatures to extreme cold, from high humidity to dust-filled environments. Their encapsulation and sealing protect them from these environmental factors, ensuring long-lasting and stable data transmission.

Q: How do slip rings contribute to the reduced maintenance needs of systems?

A: Slip rings reduce the maintenance needs of systems by using wear-resistant materials and contact designs that promote low friction. Furthermore, new developments such as wireless slip rings (rotary transformers) eliminate the need for physical contact between the brushes and the rings, significantly reducing wear and improving lifespan.

Q: How are slip rings adapting to the rise of IoT and Industry 4.0?

A: With the rise of IoT and ‘Industry 4.0,’ there is an increasing need for devices that can handle complex data and power transmission requirements while integrating with digital networks. The latest generation of slip rings is designed to handle high-speed data and power transmission through a single device, making them ideal for integration with IoT devices and smart factory applications.

These frequently asked questions provide a brief insight into the crucial role that slip rings play in digital data transmission. The continual development in this field is expected to bring about innovative slip ring designs that enhance their functionality and reliability, meeting our ever-evolving technological needs.

See What We Can Do