Slip rings are electromechanical devices that facilitate the transfer of electrical power or signals from a stationary source to a rotating component. They play a crucial role in making sure that constant electrical connectivity is maintained, even when parts are in motion. Widely utilized in various industries for enabling continuous electrical connections, slip rings help ensure the proper functioning of complex machinery and equipment.

In the context of agriculture, slip rings have emerged as vital components due to their ability to enhance the functionality of modern farming equipment. As agriculture embraces technological innovations, slip rings have become an indispensable asset in making agricultural machinery more efficient and versatile. These devices are commonly found in irrigation systems, harvesting equipment, precision agriculture tools, and alternative power sources. By integrating slip rings into agricultural machinery, farmers experience an increase in productivity, reduced downtime, and improved resource management.

The coherence lies in the fact that slip rings seamlessly complement advances in agricultural technologies. As farming practices become more sophisticated, slip rings provide the necessary electrical connections to ensure that these innovations operate smoothly and effectively. Consequently, the importance of slip rings in agriculture is expected to grow in tandem with the evolution of modern farming equipment and strategies.

Understanding Slip Ring Applications In Agriculture

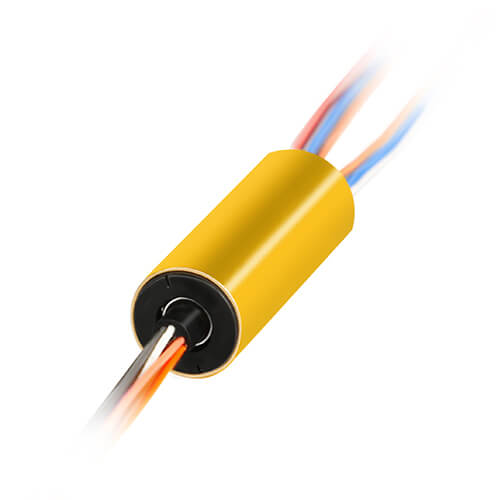

A slip ring, often referred to as a rotary electrical interface, commutator, or swivel, primarily consists of two parts: a stationary graphite or metal brush which contacts the outer segment, and a rotating ring. The stationary brush carries the electrical signal or current from a static structure to the rotating ring. As the ring rotates, it maintains an electrical connection, allowing the current to stream without interruption. This rotatory motion is typically facilitated by bearings that support the mechanism.

The underlying principle of a slip ring’s operation involves the use of an electrical interface between a stationary and a rotating part. The slip ring assembly ensures that even while in motion, a reliable electrical connection is sustained, thereby enabling the connected device to function optimally without disruptions.

Various Types of Slip Rings Are Used in Agriculture

There are several types of slip rings, each with unique characteristics and advantages, used in agricultural applications.

Capsule Slip Rings: Due to their compact design, these slip rings work well for equipment with limited installation space. These are commonly used in small motors such as those found in automated feeding systems.

Pancake Slip Rings: Named for their flat shape, these slip rings are used where height is a constraint. They typically find usage in heavy machinery like tractors and harvesters.

Through Bore Slip Rings: These slip rings accommodate a central hole for the passage of shafts or other elements, allowing added versatility in installation. They are used in a variety of machines including center pivot irrigation systems.

Wireless Slip Rings: Leveraging advanced technology, wireless slip rings eliminate physical contact, reducing wear, and maintenance. They are gaining popularity in precision farming equipment and drones.

Ethernet Slip Rings: For machinery requiring high-speed data transmission like GPS systems, these slip rings are used.

The coherence in this segment lies in the intricate operation of slip rings and their respective designs that suit various agricultural machinery requirements. The design and functioning of the slip ring are closely aligned to ensure optimal performance of different farming equipment, making them an integral cog in the wheel of present-day agricultural machinery.

Importance of Slip Rings in Agriculture

In the agricultural sphere, most machinery and equipment are subject to continuous or rotational movement. Consequently, there arises a need to sustain uninterrupted electrical power or signal transmission between stationary and rotating parts of these machines. Slip rings, in this context, play a pivotal role as they are explicitly designed to fulfill this necessity.

For instance, in a center pivot irrigation system, the central part remains stationary, while the outer components rotate around the field to distribute water evenly. Here, a slip ring helps in transferring power from the stationary part to the rotating unit, ensuring the irrigation process is not disrupted. Similarly, in GPS-operated machinery, slip rings enable the continuous flow of data signals required for precise navigational and operational accuracy.

Slip rings have a profound effect on agricultural productivity and efficiency enhancement. By assuring the uninterrupted transfer of power and signals, slip rings reduce the probability of mechanical interruption, thus contributing to a more streamlined operation of agricultural machinery.

For instance, with slip rings in irrigation systems, farmers can ensure a more uniform and efficient distribution of water, reducing water waste and improving crop yields. In combine harvesters, their contributions enhance the machine’s running time, reducing the downtime linked to friction or connectivity issues, hence increasing harvest speed and efficiency.

Moreover, in precision agriculture, where GPS and other sensory devices warrant an incessant data flow, slip rings’ role is paramount. By providing stable data transmission, they help improve yield accuracy, resource allocation, and crop health monitoring.

The context’s coherence lies in how the unique functionality of slip rings caters to the specific needs of agricultural machinery. Their integral role in maintaining seamless power or signal transmission underpins the operation of various agricultural devices, directly impacting productivity and efficiency. Consequently, understanding slip rings’ utility helps to illuminate their importance amidst the technological revolution in agriculture.

Applications of Slip Rings in Agriculture

Slip rings are integral components of various farming equipment, contributing substantially to enhanced operational efficiency and convenience. Four key farming applications of slip rings include irrigation systems, harvesting machines, GPS systems, and wind turbines.

- Irrigation Equipment

- Center Pivot Irrigation Systems: These large-scale irrigation systems employ slip rings for transferring electricity reliably from the stationary center pivot to rotating arms. Without the slip rings, maintaining a constant electrical connection while the arms rotate around the field wouldn’t be possible.

- Harvesting Machines

- Combine Harvesters: These complex machines perform several operations like reaping, threshing, and winnowing. The rotating parts inside these machines, such as the cutting mechanism, need continuous electrical power, facilitated by the slip rings.

- GPS Systems

- Precision Farming Equipment: Complex GPS systems use slip rings to ensure continuous transmission of position and navigation signals from stationary components to rotatable parts like antennae or sensors.

- Wind Turbines

- Small-scale Wind Farms for Power Supply: Slip rings in wind turbines transfer electrical power from the rotating wind turbine blades to the stationary grid connection.

The coherence in this context lies in the functional versatility offered by slip rings across a diverse set of agricultural applications. Slip rings are key to maintaining the uninterrupted working of farming equipment, from irrigation to harvesting to precision farming to renewable energy systems, offering remarkable benefits in each case. By enabling streamlined operations and minimizing work stoppages, slip rings serve as catalysts in advancing agricultural productivity and efficiency.

Key Considerations for Using Slip Rings in Agriculture

Determining the appropriate slip ring type for an agricultural application involves several key factors:

- Compatibility: It’s crucial to ensure the slip ring selected is compatible with the machines or equipment. Both the physical dimensions and electrical requirements should be matched.

- Operating Environment: The operating environment of your farm machinery contributes significantly to the selection process. Consider aspects like exposure to dust, water, extreme temperatures, and other harsh conditions. Certain slip rings are specially designed to withstand such conditions.

- Rotation Speed: The rotational speed of the parts where the slip ring will be installed is also a critical factor. Slip rings operating at high speeds typically require special designs to manage the centrifugal forces.

- Number of Circuits: The number of circuits required influences the type and size of the slip ring to select. Devices with numerous circuits might need larger or specially made slip rings.

- Type of Signal/Current: The type of signals or currents – whether data signals, power currents, or both – also plays a role. For example, Ethernet slip rings might be needed for high-speed data transmission.

Tips and Guidelines on the Maintenance and Care of Agricultural Slip Rings

Just like any other mechanical component, slip rings also require maintenance for efficient operation and increased longevity. Here are some tips:

- Regular Cleaning: It’s important to clean slip rings regularly, removing dust and grime that could cause wear and tear.

- Proper Installation: Make sure the slip ring is installed correctly. Improper installation can not only hinder its function but may also damage the device.

- Avoid Overloading: Stay within the operation parameters specified by the manufacturer to avoid overloading the slip ring, which could lead to early failure.

- Periodic Inspections: Regularly inspect the slip ring for any wear or mechanical issues. Early detection of problems may prevent severe damage and extend the lifespan of the part.

- Scheduled Replacement of Parts: Certain elements of a slip ring, such as the brushes, might need periodic replacement due to wear. Follow the manufacturer’s guidelines on this.

The coherence in this context lies in the preparation and measures needed to optimize the use of slip rings in agricultural settings. By understanding the essentials of slip ring selection and being aware of necessary maintenance practices, farmers can ensure that the slip rings used in their machinery execute their critical roles efficiently and persistently, thus safeguarding their investments in valuable farming equipment.

Challenges and Solutions in Using Slip Rings in Agricultural Settings

When using slip rings in an agricultural environment, several specific challenges often emerge:

- Harsh Environment: Farm equipment is frequently exposed to dust, moisture, and extreme weather conditions, which can cause wear and tear on slip rings over time.

- High Demand for Uninterrupted Operations: Agriculture is a time-sensitive sector, where efficiencies come from continuous operation. Interruptions due to slip ring failure could have significant implications for operational productivity.

- Complex Installation and Replacement: Installing and replacing slip rings could be a complex process, requiring a high level of technical expertise.

- Regular Maintenance Requirement: Slip rings require consistent maintenance, which may add to operational costs and time in a farming setting.

Suggestions and Solutions for Challenges

Despite these challenges, there are several strategies for overcoming these issues:

- Use Slip Rings Designed for Harsh Environments: Protect the longevity of your slip rings by choosing ones specifically designed to withstand harsh environmental conditions. This could include features like waterproof or dustproof housings.

- Use High-Quality, Reliable Slip Rings: To ensure continuous operation, choose high-quality slip rings reputed for their reliability. This way, unexpected breakdowns, and subsequent productivity losses can be significantly minimized.

- Training on Installation and Replacement: Investing in training for proper slip ring installation and replacement can save time and reduce the chances of incorrect installation or associated issues.

- Scheduled Maintenance Program: Implementing a regular maintenance program will provide early detection of potential issues and prevent severe damage, thereby ensuring consistent farm operations and reducing operational costs in the long term.

The coherence in this context lies in understanding both the potential challenges in slip ring usage and the effective solutions that balance them. By proactively addressing these common issues, users can maximize the value of their slip rings, safeguarding the operational efficiency of their agricultural machinery and maintaining high productivity. Issues like environmental damage, operational interruptions, installation complexities, and maintenance needs often impact slip ring efficiency. However, through insight, planning, and informed choices, users can ensure their slip rings continue to be valuable contributors to their farming operations.

Future Trends in Agricultural Slip Ring Applications

Recent years have seen steady advancements in slip ring technology that could greatly benefit agricultural applications.

- Improved Durability: There’s ongoing development of slip rings designed to withstand even harsher conditions, which bodes well for the demands of agricultural environments.

- Integrated Technologies: There’s an increase in slip rings that integrate other technologies such as Fiber Optics and Ethernet. These offer high-speed data transmission capabilities, vital for precision farming and real-time data analysis.

- Miniaturization: Advances in miniaturization are producing smaller, lighter, and more efficient slip rings, making them more viable for use in compact devices or machinery.

Looking ahead, the following trends are anticipated with the continuous advancement in slip ring technology:

- Wireless Power Transfer: Although this technology is still in its infancy, the future could see slip rings designed to transmit power wirelessly, completely eradicating wear and tear issues.

- Smart Monitoring: With the onset of IoT technology, future slip rings could incorporate self-monitoring capabilities, alerting maintenance staff about upcoming failures, wear and tear, or the need for part replacements.

- Energy Efficiency: As energy conservation gains prominence globally, the development of energy-efficient slip rings that minimize energy loss during transmission could be a crucial trend.

The coherence in this context links the recent advancements and future trends in slip ring technology. By continuously adapting and evolving, slip rings are set to meet the growing demands of the agriculture sector and shape future farming practices. These transformative trends, from improved durability and integrated technologies to wireless power transfer and smart monitoring capabilities, underline the role of slip rings in the agriculture sector’s future, driving productivity, and promoting sustainable practices.

Conclusion

Slip rings play a crucial role in agriculture by enabling the continuous and seamless transmission of electrical power and signals within rotating machinery. Their importance lies in their ability to support essential agricultural equipment, such as irrigation systems, harvesters, and various other farming apparatuses. The key benefits that slip rings bring to agriculture include increased operational efficiency, minimized interruptions, and improved resource management.

As agriculture continues to advance, and the industry embraces precision farming and data-driven decision-making, slip rings will be vital contributors in supporting this progress. The ongoing development of slip rings designed to endure harsh environments, support integrated technologies, and be energy-efficient is shaping the future of agriculture. By understanding the critical factors for selecting the right slip rings, being aware of their maintenance needs, and being ahead of the curve in technological advancements, the agriculture sector can harness the true potential of slip rings.

The coherence in this context highlights the essential role and benefits that slip rings offer in agricultural applications while underscoring their ongoing contributions to the sector’s future. By accentuating the importance and benefits of using slip rings in agriculture, this conclusion affirms the integral part they play in driving advancements and improvements in farming practices, ultimately supporting a more productive and sustainable agricultural landscape.

FAQs about Slip Ring Applications In Agriculture

Here are some common questions that arise regarding the use of slip rings in an agricultural setting:

Q: What is a slip ring and how does it work in agricultural machines?

A: A slip ring is an electrical device that allows the transmission of power and electrical signals from a stationary part to a rotating component. In agricultural machines like irrigation systems and harvesters, slip rings enable the apparatus to operate continuously without interruption due to rotation.

Q: Can a slip ring operate under harsh environmental conditions like dust and moisture?

A: Yes, certain slip rings are designed to resist harsh environmental conditions. They come with special features like waterproof, dustproof, or corrosion-resistant housings to enhance their durability and longevity in agricultural environments.

Q: How long does a slip ring last?

A: The lifespan of a slip ring depends on its quality, operating conditions, and maintenance routine. A well-maintained, high-quality slip ring can last for several years. Regular cleaning, proper installation, and inspection can greatly increase its lifespan.

Q: Do slip rings require regular maintenance?

A: Yes, like any other mechanical components, slip rings require regular maintenance for effective operation. This includes regular cleaning, inspection, avoiding overloading, and proper installation.

Q: Where can I get professional assistance for installing or replacing slip rings?

A: Many slip ring manufacturers or distributors offer installation assistance or provide detailed guides. You could also seek help from a local technician with experience in dealing with agricultural machinery.

See What We Can Do