Motorcycles, especially dirt bikes, have grown incredibly complex in circuit design and functionality. As a result, the electrical transfer systems have grown significantly. A key player in this system, which often goes overlooked, is the slip ring. Slip rings play a vital role in ensuring constant continuity of electricity amidst relative movement, improving both the performance and safety aspects of dirt bikes significantly.

The term ‘slip ring’ may seem technical and beyond the grasp of many dirt bike enthusiasts. However, when one unravels its meaning and appreciates its functionality, it becomes an exciting part of a dirt bike’s anatomy. In essence, slip rings could be pictured as the electrical equivalent of a bike chain, carrying electrical currents instead of physical torque. They are designed to pass electrical currents between stationary and rotating parts of the bike, an action that remarkably contributes to the impressive maneuvers and durability of dirt bikes.

In a device as dynamic as a dirt bike – where numerous parts are in constant differential motion – having a seamless electrical connection between such moving components comes with a handful of advantages. Understanding these advantages, along with managing and optimizing these crucial elements, is what this guide aims to offer its readers.

In this guide, we walk you through the relevance of slip ring applications in dirt bikes, break down their workings, and explore how they contribute to ensuring peak performance. We are confident that this information would provide every dirt bike owner with the knowledge to make more informed decisions, leading to a better biking experience. Let’s ride together through this fascinating piece of technology that deserves a lot more spotlight than it currently enjoys.

Understanding the Role of Slip Rings in Dirt Bike Mechanics

Dirt Bike Mechanics – The Basics

Dirt bikes are designed to handle off-road terrain, combining power with freedom of movement. Their suspension systems, chassis design, and engines are tailored specifically to withstand bumps and jumps while providing the necessary power to propel the bike swiftly. The heart of a dirt bike’s mechanics lies in the drivetrain, where the engine’s power is transmitted to the wheels via the gearbox and chain. The engine’s energy is fueled by a mix of air, compression, spark, and fuel – the vital elements that power an internal combustion engine.

As we focus on the dirt bike’s mechanics, another crucial aspect emerges the electrical system. Present-day dirt bikes are equipped with complex electrical systems responsible for tasks such as ignition control, electric starting, lighting, and instrument panel operation. The efficiency of a dirt bike’s electrical system plays a vital role in maximizing power output and enabling a comfortable and customizable riding experience.

The Role of Slip Rings in Dirt Bike Mechanics

While the dirt bike’s mechanics are primarily driven by its internal combustion engine, the electrical components are essential for providing smooth operation and enhancing performance. In such a dynamic environment, where various rotating and stationary parts interact, slip rings serve as a fundamental connector between these components.

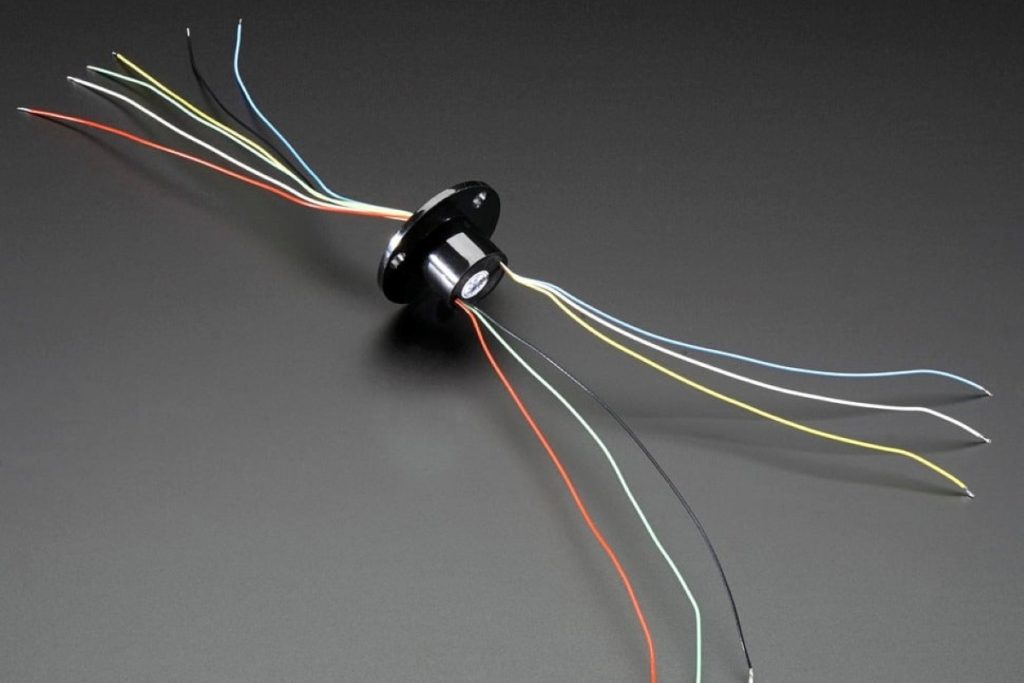

Slip rings are electromechanical devices designed to transmit electrical power or signals between stationary and rotating parts. They enable the transfer of electricity while maintaining a continuous, uninterrupted connection despite the constantly changing positions of connected parts. Consequently, slip rings play an essential role in preventing electrical wires from tangling, ensuring that the constant rotation or movement of the dirt bike’s components does not disrupt electrical power flow.

In a dirt bike, slip rings can be found in several locations. They are frequently used in the transmission of electricity to lights, instrument panels, and even sensors on the bike. Their purpose is to maintain a consistent and dependable electrical connection that can withstand the extreme conditions and movements a dirt bike experiences during its operation.

In summary, slip rings carry great importance in the overall electrical functionality of a dirt bike. Understanding their purpose and role in these mechanics allows dirt bike enthusiasts to better appreciate their impact on performance and the importance of their maintenance.

Examining the Importance of Slip Rings in Enhancing Dirt Bike Performance

How Slip Rings Contribute to Optimal Dirt Bike Performance

Slip rings are paramount for ensuring optimal dirt bike performance and contribute extensively to its overall functionality. When it comes to features like lights and the instrument panel, slip rings ensure that power is transmitted consistently, regardless of the bike’s rotational movement or changes in the rider’s position. Additionally, slip rings assist with integrating advanced electrical systems like anti-lock braking and traction control, making the dirt bike safer and more effective on different types of terrains.

Aside from enhancing performance, slip rings on a dirt bike also aid in minimizing mechanical wear and electric noise. Reduced wear translates to better performance in components, such as suspension and other moving parts. Furthermore, effective power transmission through the slip rings results in lower energy losses and improves the bike’s overall efficiency and reliability.

Potential Issues in the Absence of Appropriately Functioning Slip Rings

Without properly functioning slip rings, a dirt bike can experience several issues affecting its performance and safety. These adverse effects range from electrical inconsistencies to possible breakdowns. A few examples of potential issues faced by dirt bikes due to malfunctioning slip rings are:

- Intermittent or complete loss of electrical power to important components such as lights, sensors, or the instrument panel, which could lead to difficulty in viewing crucial information or lack of rider visibility in low-light conditions.

- Increased mechanical wear, caused by friction between stationary and rotating parts, could lead to reduced component lifespan, increased maintenance costs, and overall poorer ride quality.

- Electrical arcing and noise, resulting in interference with other electronic systems on the bike and reducing overall reliability.

- Increased safety risk for the rider, especially during off-road excursions, such as navigating muddy terrains, since advanced safety systems like anti-lock braking or traction control could fail without proper slip ring functionality.

In conclusion, slip rings play an essential role in enhancing dirt bike performance and mitigating potential operational problems. Their contribution to maintaining smooth electrical connections helps in ensuring not only optimal dirt bike operation but also rider safety. Recognizing their importance and understanding their impact on performance is crucial for every dirt bike enthusiast to make informed choices and assess their bike’s condition correctly.

Specific Applications of Slip Rings in Dirt Bikes

Several Applications of Slip Rings in Dirt Bikes

Dirt bikes, with their advanced mechanics and need for constant agility, utilize slip rings in different ways to ensure seamless operation. Slip rings transfer electricity from the dirt bike’s stationary components, like the battery and generator, to its rotating parts, like the wheels and the handlebars. This is a broad overview, but specific applications are even more intriguing:

- Lights and Indicators: The foremost area where slip rings make their presence felt is in managing the power supply to a dirt bike’s lights. Whether it’s driving lights, indicators, brake lights, or even the taillights, all require a constant power supply to function – a need fulfilled by slip rings.

- Instrument Panels: Instrument panels, such as speedometers, fuel gauges, and temperature gauges, need a steady flow of electrical power to keep the rider informed. Tachometers especially spin in conjunction with the bike’s engine speed, making slip rings essential for their functioning.

- Starters: Electric starters use slip rings to transfer the substantial current required to turn the motor and start the bike. This high power transfer is efficiently managed through the use of slip rings.

- Anti-Lock Braking Systems (ABS) and Traction Control: Advanced safety systems present in modern dirt bikes, such as ABS and traction control, receive power and communicate with the rest of the bike through electrical connections maintained by slip rings.

Features Facilitated by Slip Rings in Dirt Bikes

The multifaceted role of slip rings also facilitates a number of high-level features in dirt bikes:

- Stability of Electrical Connections: Slip rings provide a stable electrical connection, ensuring a constant power supply. This stability is essential for continuity in the operation of features like lights, instrument panels, and safety systems.

- Integration of Advanced Systems: Advanced dirt bike technologies, such as electric starters, ABS, and traction control, are only possible with slip rings’ efficient electrical power transfer.

- Reduced Electrical Noise and Interference: High-quality slip rings help decrease electrical noise, thus ensuring that all electronic systems on the dirt bike work efficiently without signal interference.

The ubiquitous presence of slip rings and their diverse applications underscore their importance in the overall performance of dirt bikes. Understanding these applications will help riders maintain and troubleshoot issues, thereby enjoying a smoother and safer ride.

Choosing the Appropriate Slip Ring for Your Dirt Bike

Factors to Consider When Selecting Slip Rings for Dirt Bikes

When selecting the right slip ring for your dirt bike, it’s crucial to consider certain factors to ensure compatibility with your bike’s model, improve its performance, and enhance your ride safety:

- Bike Model and Specifications: Different models of dirt bikes may require different configurations of slip rings, based on factors like design and electrical system complexity.

- Material Quality: The material of the slip ring impacts its longevity and performance. High-quality materials provide better conductivity, enhanced durability, and resistance to vibrations and wear.

- Operating Conditions: Off-road dirt bikes encounter harsh operating conditions. Choosing slip rings that can withstand these conditions without compromising performance is critical.

- Power Requirements: The power needs of your bike’s electrical systems, such as lights, indicators, and advanced safety features like ABS, will determine the necessary specifications of the slip ring.

Guide to Identifying the Right Slip Ring for Dirt Bike Models

Choosing the right slip ring may seem daunting, given the variety of bike models and feature sets. However, understanding your bike’s requirements and the basic functionality of slip rings can greatly simplify this task. Below are a few steps to help you identify the appropriate slip ring:

- Verify Your Bike’s Model: Check your bike’s make and model. Typically, the manufacturer provides detailed specifications that include the type of slip ring needed. Most manufacturers or bike shops can also provide advice on suitable replacements or upgrades.

- Analyze Your Bike’s Specification: Look into your bike’s specifications like engine power, electrical system setup, and additional features. These will help you determine the required slip ring’s power capacity, built material, and other specifications.

- Consult Professionals: When in doubt, seek professional advice. Mechanics or professional dirt bike enthusiasts can provide precious insights about the brands and models of slip rings that work best with specific bike models.

- Read Reviews: Going through online user reviews can also be informative. Reviews from other dirt bike owners can give you a better understanding of the real-world performance of different slip ring brands and models.

Remember that a dirt bike is only as good as the parts you put in it, and slip rings are no exception. Thus, while choosing the right slip ring may require some due diligence, it is definitely worth the effort for the overall performance and safety.

Caring for and Maintaining Dirt Bike Slip Rings

Importance of Routine Maintenance for Slip Rings in Dirt Bikes

Routine maintenance of slip rings is vital for ensuring the smooth functioning and longevity of your dirt bike’s electrical components. Dirt and debris can accumulate on and around slip rings, causing increased friction and wear. As a result, it can negatively impact power transfer, component life, and ride quality.

By regularly checking and maintaining slip rings, you can prevent potential damage to your dirt bike, ensure optimal performance, and minimize the risk of breakdowns. Proper maintenance also helps in reducing electrical noise, which can interfere with other electrical systems and sensors.

Tips on Slip Ring Cleaning and Upkeep

Here are some tips for properly cleaning and maintaining your dirt bike’s slip rings:

- Inspect Regularly: Make a habit of inspecting your slip rings at regular intervals or during dirt bike servicing. Check for signs of wear, corrosion, or debris accumulation.

- Clean Debris: Remove any visible dust or debris around the slip rings. Use a soft brush or cloth to clear away dirt without damaging the slip ring or its connectors.

- Clean Contacts: The contact points between the slip ring and brushes should be kept clean to ensure proper electrical conductivity. Use a contact cleaner to remove dirt, grease, or oxidation from the contacts. Ensure that you choose a cleaner that is specifically designed for slip rings, as unsuitable cleaners can cause damage.

- Lubricate When Necessary: Some slip rings may require lubrication. Be sure to consult the manufacturer’s recommendations regarding the lubricant type and application method. Apply lubricant sparingly to avoid dust accumulation.

- Monitor Electrical Performance: Keep an eye on the performance of electrical systems, such as lights and instruments. If you notice any fluctuations or issues, it could indicate a problem with the slip rings. Address any such issues promptly.

Resources for Slip Ring Replacement or Repair Services

If you need assistance with slip ring maintenance or replacement, consider the following resources:

- Dirt Bike Manufacturer: Your dirt bike manufacturer might provide specific guidelines, recommendations, or support for slip ring replacement or maintenance.

- Authorized Dealerships and Repair Centers: Find an authorized dealership or repair center in your area. They can provide you with expert advice and may offer specialized services for your bike model.

- Online Forums and Communities: Interacting with other dirt bike enthusiasts and experts can also be beneficial. You may find helpful discussions, advice, and recommendations on slip ring maintenance, replacement, or repairs within these communities.

- Tutorials and Videos: Numerous tutorials and videos are available online for slip ring maintenance and replacement. These instructional materials can be invaluable in guiding you through the process.

The importance of proper slip ring maintenance and care, alongside the availability of valuable resources, should keep you well equipped for the upkeep of your dirt bike’s electrical health. By following these guidelines, you can ensure your ride stays smooth, safe, and enjoyable.

Future Trends in Dirt Bike Slip Ring Application

As technology continues to advance, slip rings are no exception. Current developments in slip ring technology offer several potential benefits and applications for dirt bikes. Understanding these advancements will help riders and manufacturers alike stay informed and make better decisions regarding maintenance, customization, or design improvements.

Latest Advancements in Slip Ring Technology for Dirt Bikes

- Improved Materials and Designs: Recent advancements have led to the use of better materials and design techniques, resulting in slip rings with increased conductivity, durability, and resistance to environmental factors. For example, the use of precious metal alloys has been found to enhance conductivity while ensuring minimal wear and tear.

- Wireless Data Transfer: As the communication and control systems of modern dirt bikes become increasingly sophisticated, so does the need for more efficient data transfer methods. Some slip rings now incorporate wireless data transmission techniques, allowing for seamless communication between bike components without physical contact.

- Miniaturization: As dirt bikes become more compact, so do their slip rings. Technological advancements have resulted in smaller, more efficient slip rings, reducing the overall weight of the bike and freeing up space for other components.

- Increased Power Transfer Capacity: Innovations in slip ring technology have enabled them to transmit higher levels of electrical power without compromising performance. This increased capacity will allow dirt bikes to accommodate more powerful electrical systems, such as lights and electronics.

Possible Impact of These Developments on Dirt Bike Functionality

The introduction of advanced slip ring technology in dirt bikes will have a significant impact on their functionality in the following ways:

- Enhanced Performance: Improved slip rings allow for better power transfer, resulting in more efficient operation of electrical components, such as lights and advanced safety systems. This equates to better overall performance of the dirt bike, ensuring a smoother and safer ride.

- Greater Customization: As slip rings become more versatile and efficient, dirt bike owners can install additional advanced electronics and systems on their bikes, allowing for increased customization and personalization.

- Longevity and Durability: The use of better materials and designs in slip ring manufacturing will result in extended durability, decreasing the need for frequent slip ring replacements and maintenance.

- Eco-Friendly Solutions: Improved slip ring technology can contribute to energy efficiency and a reduction in the environmental impact of dirt bikes. Better power management and decreased wear can lead to less energy waste and fewer discarded components.

By staying informed of these advancements and their potential impact on dirt bike functionality, riders and manufacturers can make the most of the progressing technology and reap the subsequent benefits.

Conclusion

In this comprehensive guide, we have explored the fundamentals, importance, and applications of slip rings in dirt bikes. Let’s recap the key aspects discussed throughout the guide:

- Understanding Slip Rings: Slip rings are electrical connectors used to transmit power and signals between stationary and rotating components, playing a crucial role in dirt bike electrical systems.

- Functioning and Types: From basic designs and fiber brush technology to mercury-wetted slip rings, we have discussed the different types and properties of slip rings relevant to dirt bikes.

- Maintenance and Cleaning: Regular inspection, proper cleaning, and lubrication (if required) are essential for maintaining steady performance as well as the longevity of slip rings in dirt bikes.

- Future Trends: Advancements in slip ring technology, such as improved materials, miniaturization, and wireless data transfer, promise to enhance dirt bike functionality and performance in the future.

- FAQs: We addressed some common questions and concerns regarding slip ring application in dirt bikes to provide clarity and dispel any doubts.

As a dirt bike enthusiast, we encourage you to consider your slip rings’ importance, experiment with upgrades, and stay informed about advancements in slip ring technology. Continually striving to unlock the full potential of your dirt bike by paying attention to critical components like slip rings not only ensures a smoother, more efficient ride but also guarantees long-lasting performance and a superior riding experience. Happy trails!

FAQs about Slip Ring Application in Dirt Bikes

This section is aimed at addressing some of the most frequently asked questions about slip ring applications in dirt bikes. Whether you’re curious about the role of a slip ring in a dirt bike, the process of maintenance, or how to upgrade, these answers should help clear any doubts or queries you might have:

Fill Out the Inquiry Form for Slip Ring Availability and Pricing.

Q: What is the role of a slip ring in a dirt bike?

A: In a dirt bike, a slip ring’s main role is to enable the uninterrupted transmission of electrical power and signals from stationary parts to rotating parts of the bike. For instance, it allows electrical current to pass from the stationary battery to the rotating wheel system (lights, sensors) seamlessly despite the continuous motion.

Q: How frequently should I check or maintain my dirt bike slip ring?

A: The frequency of slip ring maintenance varies depending on your bike usage and the conditions in which you ride. However, it’s generally recommended to inspect and clean the slip ring during every dirt bike service or when the bike’s electrical system shows signs of irregularity.

Q: Can I replace or upgrade a slip ring myself?

A: Yes, it’s possible to replace or upgrade a slip ring yourself if you have the necessary tools and knowledge. However, it’s recommended to consult the bike manufacturer’s guidelines or seek assistance from a professional mechanic to ensure the correct replacement or upgrade is made.

Q: How do I know if my dirt bike slip ring is failing?

A: Signs of a failing slip ring can include fluctuations in the bike’s electrical system, flickering lights, or reduced performance of electrical components. If you encounter these issues, inspect the slip ring for signs of wear, corrosion, or excess debris.

Q: Can I customize my slip ring for specific needs?

A: In most cases, slip rings are designed to meet the bike’s specific requirements. However, with the advancement of slip ring technology, some types may offer options for customization, such as increased power transfer capacity or incorporation of advanced data transmission features.

The complexity of dirt bikes, especially their integrated electrical systems, can seem overwhelming at first glance. Nevertheless, equipping yourself with the right knowledge—much like this FAQ list—goes a long way in maintaining, troubleshooting, and enhancing your beloved ride.