With the constant evolution in technology, industrial machines have become more complex and efficient. Their improved performance is largely credited to their intricate components, which ensure seamless operation. Amongst these, slip rings hold a special place due to their unique functionality. This guide aims to present a detailed understanding of slip ring applications in Pallet Machines, elucidating their substantial role in making these machines more effective and reliable.

Slip rings, or rotary electrical joints as they’re often known, are devices specifically designed to transmit electrical power and signals from a stationary structure to a rotating part. In their application to pallet machines, they perform an essential role in maintaining the continuous flow of electricity to keep the machinery running optimally. These devices are ingeniously built to combat the challenges that crop up due to the constant rotation of parts in pallet machines.

By ensuring a stable and uninterrupted transmission of power, slip rings liberate pallet machines from operational restrictions, thereby expanding their capabilities. Primarily, they make it possible for pallet machines to function with higher operational efficiency, more reliably, and with less maintenance. This guide will take you through the importance of these devices, deep diving into their mechanisms, benefits, common issue resolutions, and routine maintenance in the context of pallet machines. It will help you realize the significant difference that the application of slip rings can make in the machinery’s general functionality, as well as their contribution to elevating the overall performance standards of modern pallet machines.

The Crucial Role of Slip Rings in Pallet Machines

The success of any mechanical operation hinges on the effectiveness of its components, and in the world of pallet machines, slip rings bear a significant influence. These devices act as the beating heart of the machinery, embedding themselves in the very core of a pallet machine’s functioning, by assuring the steady transmission of power and signals.

While the physical construct of a slip ring may seem straightforward—a ring that encircles a rotating shaft, maintaining physical contact to enable energy transfer—it is this simple configuration that enables complex operations within the pallet machine. The slip ring essentially acts as a bridge, enabling the transition of power and signals to the machine’s rotating components. This, in turn, allows various parts of the machine to work simultaneously and harmoniously, despite their constant motion.

So, why are slip rings considered essential in pallet machines? The answer lies in the very nature of these machines’ operations. Pallet machines, by design, involve considerable rotational activity. Without an efficient method to transmit power to moving parts, the machine would be unable to perform its tasks. Here, slip rings come into play, carrying the requisite electric current or signals across rotational interfaces, thereby ensuring that the machine works as intended. The slip rings’ presence ensures the machine’s consistent operation, while their absence would bring everything to a standstill, highlighting their indispensability.

Moreover, slip rings empower pallet machines to operate with fewer restrictions, allowing for a broader range of functionalities. With the energy transition challenge solved by the slip rings, pallet machines can pull off diverse tasks beyond their basic function of moving and stacking pallets. Thus, in the context of pallet machines, slip rings truly hold a crucial, almost irreplaceable role.

Delving into the Mechanism: How Slip Rings Work in Pallet Machines

As stated earlier, slip rings serve the purpose of transferring electric power and signals between the stationary and rotating parts of a pallet machine. To understand their significance, it’s essential to examine their working mechanism within these machines.

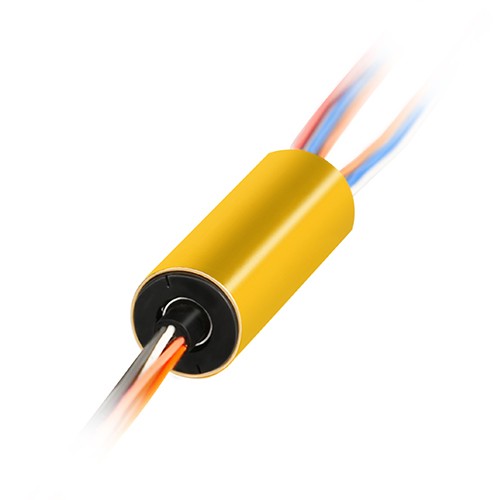

A typical slip ring comprises two primary components: the ring itself, which is affixed to the rotating section of a machine, and brushes that maintain contact against the ring’s surface, permitting an electrical connection between the rotating and stationary parts. When pallet machines are in operation, the electric current or signals pass through these brushes, which glide over the rings. This interaction between brushes and rings maintains a continuous flow of power while allowing for the machine’s rotation.

Within the realm of pallet machines, different types of slip rings cater to the varied requirements of machine operations. Some of the most common slip ring types found in these machines are:

- Conventional Slip Rings: These slip rings feature metal brushes making contact with the rings. Suitable for basic pallet machine operations, they are often distinguished by the number of electric channels they offer.

- Fiber Brush Slip Rings: Adopting metal or metal-alloy brushes in the form of multiple contact fibers, fiber brush slip rings boast low electrical noise and reduced maintenance needs. They’re well-suited for advanced pallet machines requiring smoother power transmission.

- Capsule Slip Rings Compact in design, capsule slip rings are perfect for applications where space is a premium. Pallet machines that need to house slip rings in limited space can rely on these tiny but powerful performers.

- Mercury Wetted Slip Rings: Employing liquid mercury as the conducting medium, these slip rings provide low resistance and minimal electrical noise. They are typically utilized in specialized pallet machines where higher precision and efficiency are required.

The choice of slip ring depends on the particular needs of a pallet machine. Parameters such as electric current handling capacity, signal types, number of channels, and overall system requirements guide the selection process. By integrating the appropriate slip ring type, the pallet machine’s efficiency, reliability, and functionality can be notably optimized.

Enhancing Operations: The Benefits of Slip Rings in Pallet Machines

When exploring the contributions of slip rings to pallet machines, it’s essential to demarcate their role not only as mere functional components but also as significant contributors to optimized machine performance. Their impact on machine efficiency, reliability, and other unique benefits make them an integral piece of the machinery puzzle.

Contributing to Machine Efficiency

One of the noteworthy contributions of slip rings is their boost to the overall efficiency of pallet machines. As they seamlessly transit electrical power and signals between static and rotating parts, slip rings enable smooth and coordinated machine operation. By minimizing signal interference and ensuring a constant flow of power, they curb potential disruptions, consequently improving machine productivity and efficiency.

Adding to Machine Reliability

Furthermore, slip rings work towards enhancing the reliability of pallet machines. Their consistent delivery of power makes them a dependable component supporting machine operation under varied conditions. Even in situations of prolonged use or high rotational speeds, well-maintained slip rings ensure steady power transmission, adding to machine resiliency and dependability.

Other Unique Benefits

Besides efficiency and reliability, slip rings bring forth other unique benefits to pallet machines. One of those is their role in reducing wear and tear on machine parts. By eliminating the need for wired connections between rotating and static parts, they limit component friction, thus reducing the wear resulting from constant rubbing against each other.

In addition, slip rings have opened up avenues for ingenious machine designs. Their ability to transfer power amidst rotation allows engineers to conceive machines with enhanced multi-directional capabilities, broadening the functionality horizon of pallet machines.

In conclusion, the benefit of slip rings goes beyond their basic function of enabling power transmission. They simultaneously serve as the backbone of the machine’s efficiency, the bulwark in its reliability, and the catalyst in its innovative design possibilities, cementing their importance in the effective operation of pallet machines.

Common Problems with Slip Rings in Pallet Machines and Solutions

While slip rings play a pivotal role in maintaining the seamless operation of pallet machines, they are not immune to wear, tear, and performance issues. Addressing these hitches is intrinsic to maintaining machine operations unimpeded. This elaboration delves into the common problems faced with slip rings in pallet machines and offers helpful tips and solutions for overcoming these challenges.

Common Issues Encountered

Slip rings in pallet machines generally encounter a set of common issues resulting from different factors, typically revolving around wear and tear, contamination, and connection issues:

- Wear and Tear: Fast and continued use often inflicts wear and tear on slip rings, affecting their ability to perform optimally. The constant rubbing of brushes against rings accelerates this deterioration which can lead to efficiency loss in power transmission.

- Contamination with Dust or Debris: When pallet machines operate in industrial environments, they can get exposed to dust and debris. These particulates can settle on the slip rings and impede the seamless transfer of electric signals, affecting machine performance.

- Poor Contact: In some instances, the brushes don’t make proper contact with the rings, resulting in intermittent or disrupted power transfer. Misalignment or worn-out rings and brushes are some common causes behind this issue.

Helpful Tips and Practical Solutions to Overcome These Challenges

Despite these challenges, there are practical ways to get them well-handled and ensure the slip rings continue to function effectively:

- Addressing Wear and Tear: Regular inspections help in spotting wear and tear on the slip rings. If observed, the worn-out components can be replaced promptly, mitigating further damage or performance drops. The use of high-quality, wear-resistant slip rings can also minimize wear over time.

- Dealing with Dust or Debris Contamination: Introducing a frequent cleaning regimen for the slip rings can forestall dust or debris build-up that could hamper performance. Using suitable cleaning solutions and non-abrasive cloths can ensure an effective yet safe cleaning process. A protective cover or casing could also be employed to shield the slip rings from excess dust or debris.

- Correcting Poor Contact Issues: If there’s poor contact between the brushes and rings, it’s crucial first to find out the root cause. Once identified and fixed—be it worn-out brushes, misaligned parts, or defective rings—the contact and power transmission can see remarkable improvement.

Overall, these challenges with slip rings may seem daunting but are surmountable with appropriate identification and remedial measures. Adherence to these practical tips and guidelines can ensure the slip rings, and by extension, the pallet machines, function optimally, ensuring a consistent, reliable production process.

Maintaining Success: Tips for Caring for Slip Rings in Pallet Machines

Adequate care and maintenance of slip rings in pallet machines are essential to ensure their smooth operation and prolong their service life. Implementing a comprehensive care routine can prevent common issues and guarantee optimum performance. The following section details recommended steps for routine maintenance and guidelines for long-term care of slip rings in pallet machines.

Recommended Steps for Routine Maintenance

A consistent and detailed maintenance plan is crucial to identify potential issues early on and address them promptly. Here are some important steps to include in your routine maintenance:

- Visual Inspection: Regularly inspect the slip rings and brushes for signs of wear, damage, or contamination. Swift intervention can mitigate any performance issues and prevent further degradation of the components.

- Cleaning: Periodically clean the slip rings and brushes using appropriate cleaning solutions and non-abrasive cloths. This will help keep the components dust and debris-free, leading to cleaner power transmission.

- Performance Check: Test the slip rings’ electrical and mechanical performance by measuring their resistance, operating temperature, and vibration levels. Regular testing and recording of these parameters can alert you to any performance dips or anomalies.

- Brush Replacement: Routinely assess the condition of the brushes and replace them when they are worn out or damaged. This step is vital to ensure consistent electrical contact and minimize the risk of rings’ wear and tear.

Guidelines for Effective Long-term Care

To guarantee the longevity and performance of slip rings in pallet machines, the following long-term care guidelines should be considered:

- Quality Components: Invest in high-quality slip rings and brushes that have a longer service life and are resistant to wear and tear. This investment will pay off in the long run, as it helps avoid future breakdowns and costly downtimes.

- Proper Installation and Alignment: When installing or replacing slip rings and brushes, ensure they are aligned correctly and firmly secured. A correct installation goes a long way in preventing issues like poor contact and premature wear.

- Regular Training of Maintenance Staff: Ensure your maintenance team is well-versed with the latest best practices and industry recommendations for slip ring care. Regular training and updates can help them keep the pallet machine running efficiently while maximizing the service life of its components.

- Adherence to Manufacturer’s Instructions: Always consult and follow the manufacturer’s manuals and guidelines to prevent any unintended damage or performance issues. This includes adhering to the recommended maintenance intervals and using only specified replacement parts.

By combining routine maintenance with long-term care guidelines, you can effectively maintain the health and functionality of the slip rings in your pallet machines. The adherence to these protocols will not only prolong the slip rings’ service life but also sustain their optimal performance, leading to an efficient and reliable production process.

Conclusion

The importance of slip rings in pallet machines can’t be overstated. They facilitate the seamless transmission of power and signals from stationary to rotating components, thereby ensuring the smooth functioning of the machines. This conclusion summarises the pivotal role of slip rings and looks ahead at potential advancements in the field.

Summarizing the Integral Role of Slip Rings in Pallet Machines

Slip rings are critical to pallet machine operations. They navigate the complex technical hurdle of transferring electric energy and signals across components in relative motion. Through their action, they enable the automation of pallet machines, ensuring consistency, and reducing product handling time. Moreover, their consistent performance is paramount for the efficiency and longevity of the entire machine system. Without their inherent ability to deliver power and signals effectively, pallet machines would lose their automation capabilities, impacting productivity significantly.

A Glimpse into Future Advancements in the Field of Slip Rings in Pallet Machines

As we look to the future, the field of slip rings is ripe for potential advancements, primarily driven by increasing demands for efficiency and reliability in pallet machines. Here’s what we might see:

- More Durable Materials: Innovations are already paving the way for the use of stronger, more resilient materials in the production of slip rings. These materials would withstand higher stress levels, reduce wear and tear, and prolong service life.

- Dust and Debris Resistance: Slip rings of the future may well come with built-in resistance to dust and debris accumulation. Specialized coatings and improved sealing technologies could make cleaning intervals longer, reduce maintenance needs, and boost overall performance.

- Advanced Diagnostic Tools: Future advancements could see slip rings fitted with smart features and advanced diagnostics to automatically detect and report issues. These advancements will optimize maintenance schedules and prevent unexpected breakdowns, thereby increasing overall machine efficiency.

In summary, the role of slip rings in pallet machines is vital, and the potential for improvements is substantial. Continued innovation in this sphere will not only increase efficiency and reduce maintenance requirements but also transform the operational capabilities of pallet machines, leading to the realization of smarter, more productive manufacturing spaces.

FAQs about Slip Ring Application in Pallet Machine

In understanding and navigating slip ring applications in pallet machines, several common queries often surface. This section aims to address these questions, providing comprehensive responses to add value to your practical knowledge and understanding of slip rings in the context of pallet machines.

Q: What is the Use of Slip Rings in Pallet Machines?

A: Slip rings in pallet machines facilitate the transmission of power and signals between stationary and rotating components. Given that these machines require a smooth handling and rotation mechanism for moving loads, slip rings play a crucial role in enabling automated functions of the machines by ensuring a reliable electrical connection during rotation.

Q: What are Common Issues of Slip Rings in Pallet Machines?

A: Common issues that could arise with slip rings in pallet machines include wear and tear, contamination from dust or debris, and poor contact between brushes and rings. These issues can disrupt the smooth transmission of power and signals and consequently hamper the operation of the machine.

Q: How to Maintain Slip Rings in Pallet Machines?

A: Maintenance of slip rings involves regular visual inspection, cleaning, performance check, and timely replacement of brushes. For effective long-term care, investing in high-quality parts, ensuring correct installation and alignment, frequent training for maintenance staff, and adherence to manufacturer’s instructions are recommended.

Q: What are the Future Advancements Expected in Slip Rings for Pallet Machines?

A: Future advancements in the field of slip rings for pallet machines could include the use of more durable materials, better resistance against dust and debris, and the introduction of smart features and advanced diagnostic tools. These features will not only boost the overall machine efficiency but will also increase the lifespan of these components, making them more robust and reliable.

Looking at the intrinsic need for slip rings in the mechanical functioning of pallet machines, it becomes clear that a thorough understanding of their issues, maintenance, and potential advancements can lead to more efficient and reliable production processes.

See What We Can Do