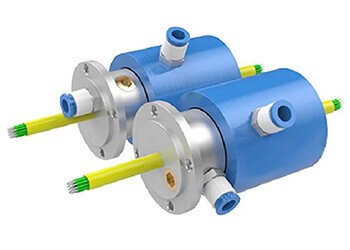

In a world where innovation knows no bounds, do-it-yourself (DIY) enthusiasts are constantly pushing the boundaries of what is possible. One such groundbreaking project gaining momentum is the DIY slip ring connector. By combining ingenuity and resourcefulness, these creative individuals have managed to develop their own versions of slip ring connectors, enabling seamless power and data transmission in rotating systems. In this article, we will delve into the world of DIY slip ring connectors, exploring their benefits, challenges, and the incredible potential they hold.

The DIY Slip Ring Connector Phenomenon

With the rise of online communities and the sharing of knowledge, DIY projects have gained immense popularity. The DIY slip ring connector movement, in particular, has garnered attention from electronics enthusiasts, hobbyists, and inventors alike. These passionate individuals have taken on the challenge of creating their own slip ring connectors, driven by the desire to overcome the limitations of traditional connectors and explore new possibilities.

Benefits and Advantages

The DIY slip ring connector offers several advantages that appeal to the maker community. Let’s take a closer look at some of the key benefits:

Cost-Effective Solution: One of the main advantages of DIY slip ring connectors is their affordability. Commercial slip ring connectors can often be expensive, especially for hobbyists or individuals working on small-scale projects. By creating their own connectors, DIY enthusiasts can save a significant amount of money while still achieving their desired functionality.

Customization and Flexibility: DIY slip ring connectors provide the opportunity for customization and flexibility. Makers can tailor their designs to suit specific project requirements, allowing for unique and innovative solutions. This adaptability empowers creators to explore unconventional applications and unleash their creativity.

Learning Experience: Developing a DIY slip ring connector is a valuable learning experience. Makers gain a deep understanding of the underlying principles and technologies involved in power and data transmission, honing their skills in electrical engineering, mechanical design, and problem-solving. This hands-on approach fosters personal growth and opens doors to new possibilities.

Challenges and Considerations

While DIY slip ring connectors offer exciting possibilities, they also come with their fair share of challenges and considerations. Makers embarking on such projects should be aware of the following factors:

Technical Complexity: Designing and building a slip ring connector requires a certain level of technical expertise. It involves understanding electrical circuits, brush contact mechanisms, insulation, and materials, among other intricate details. Makers must possess a solid foundation in electronics and mechanics to ensure the connector’s reliability and performance.

Precision and Durability: Slip ring connectors need to maintain continuous electrical contact throughout rotation, which requires precision and durability. Achieving a reliable connection over an extended period can be challenging for DIY projects due to factors such as brush wear, signal interference, and mechanical stability. Makers must carefully consider these factors to ensure the longevity and performance of their DIY connectors.

Safety Considerations: Safety should always be a top priority when working with electrical components. Makers should adhere to proper insulation practices, grounding techniques, and ensure that their DIY slip ring connectors meet safety standards. Failure to do so can result in electrical hazards, damage to equipment, or even personal injury.

Exploring Potential Applications

DIY slip ring connectors have the potential to be applied in various fields and projects. While their suitability for professional or high-demand applications may be limited, they can excel in smaller-scale projects and experimental setups. Here are a few areas where DIY slip ring connectors can find application:

Robotics and Automation: DIY slip ring connectors can enable power and data transmission between rotating joints in robotic systems. Hobbyist robot builders can utilize these connectors to achieve continuous movement and control without the limitations of traditional cables.

Photography and Videography: A DIY slip ring connector can be utilized in motorized camera rigs or rotating platforms, allowing for seamless transmission of power and data between the camera and external devices. This enables smooth, uninterrupted capture of high-quality images and videos.

Art Installations and Display Systems: Creative individuals can incorporate DIY slip ring connectors into interactive art installations or rotating display systems. This technology facilitates the transmission of power and control signals, enabling dynamic and captivating visual experiences.The DIY Community: Sharing Knowledge and CollaboratingThe DIY slip ring connector movement thrives on collaboration, knowledge-sharing, and community support. Online forums, maker spaces, and social media platforms have become hubs for exchanging ideas, troubleshooting challenges, and showcasing DIY slip ring connector projects. These spaces foster a spirit of innovation and camaraderie, inspiring individuals to embark on their own DIY journeys and push the boundaries of what is possible.

The rise of the DIY slip ring connector is a testament to the ingenuity and resourcefulness of makers worldwide. By designing and building their own connectors, DIY enthusiasts are exploring new frontiers in power and data transmission. While these DIY solutions may have limitations compared to commercial offerings, they provide cost-effective alternatives, customized solutions, and invaluable learning experiences. As the DIY community continues to share knowledge and collaborate, the potential for innovative applications of DIY slip ring connectors will only grow, propelling the maker movement forward and inspiring future generations of inventors.

See What We Can Do