In the realm of electrical engineering, achieving uninterrupted power and signal transmission in rotating systems has always been a challenge. However, with the advent of slip ring connectors, engineers have found a groundbreaking solution to this age-old problem. In this article, we delve into the electrical evolution of slip ring connectors, exploring their capabilities, applications, and contributions to seamless connectivity in a wide range of industries. Join us as we uncover the power behind these innovative electrical components.

Unleashing the Potential of Slip Ring Connectors

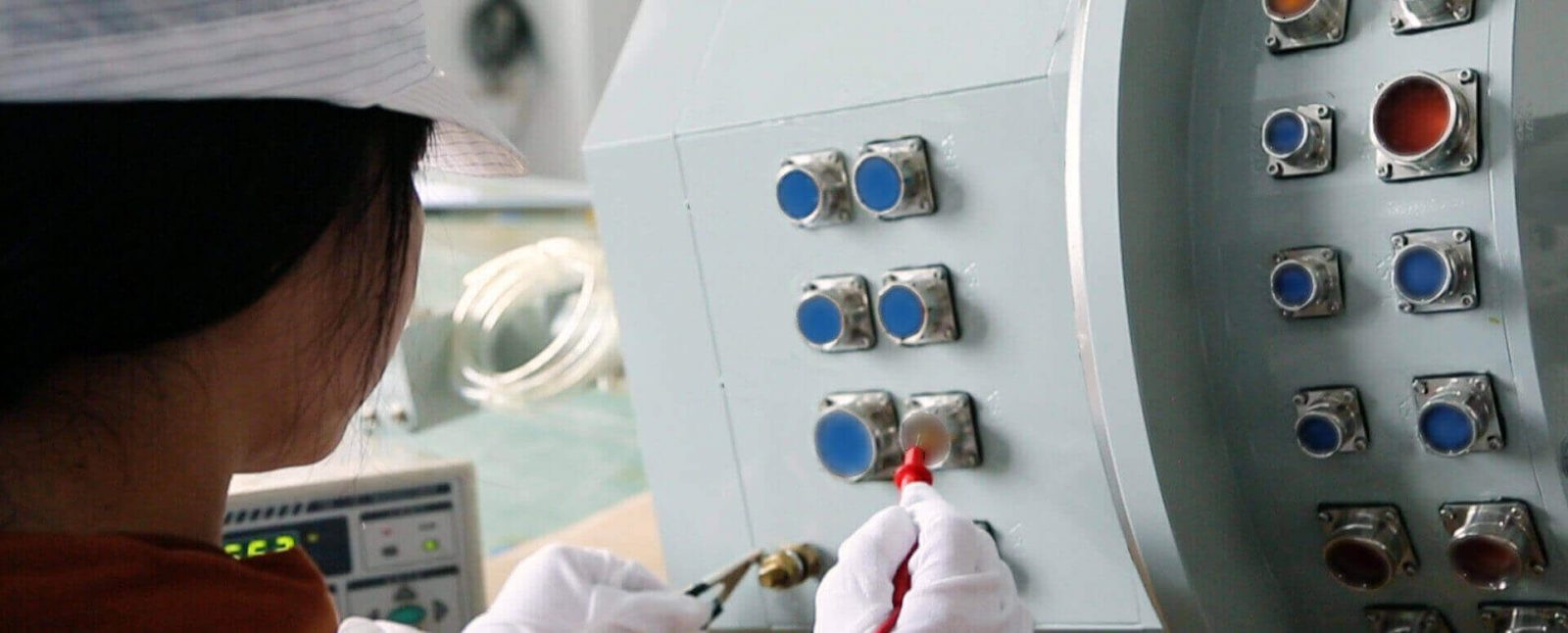

Slip ring connectors have revolutionized the way power and signals are transmitted in rotating systems. These ingenious electrical devices serve as a bridge between stationary and rotating components, enabling uninterrupted flow of electricity, data, and signals across rotating interfaces. By overcoming the limitations of traditional wiring methods, slip ring connectors have become indispensable in various industries, opening up new possibilities and enhancing system performance.

The Electrical Dynamics of Slip Ring Connectors

Power Transmission: Slip ring connectors excel at transmitting power in rotating systems. By providing a continuous electrical pathway, these connectors enable the delivery of reliable power to motors, actuators, sensors, and other electrical components. They ensure smooth and uninterrupted operation, eliminating the need for cumbersome wires or cables that can impede rotational motion.

Signal and Data Transmission: In addition to power, slip ring connectors facilitate the transmission of signals and data across rotating interfaces. This capability is essential in applications where real-time communication and data exchange are critical, such as in robotics, automation, and surveillance systems. Slip ring connectors maintain signal integrity, ensuring accurate and reliable transmission without degradation or loss.

Applications in Various Industries

Robotics and Automation: In the realm of robotics, slip ring connectors play a pivotal role in enabling seamless electrical connectivity between stationary and rotating components. They allow robotic arms and joints to rotate freely while maintaining power supply and signal transmission, enhancing the precision and versatility of robotic systems.

Wind Energy: The renewable energy sector, particularly wind energy, relies on slip ring connectors for efficient power transmission in wind turbine generators. These connectors enable the transfer of electricity from the rotating blades to the stationary components, facilitating continuous power generation and optimizing energy efficiency.

Industrial Machinery: Slip ring connectors find extensive use in various industrial machinery applications, including conveyors, cranes, rotary tables, and printing presses. By providing reliable power and signal transmission, these connectors enhance the performance and productivity of industrial systems, reducing downtime and improving overall efficiency.

Medical Equipment: In the medical field, slip ring connectors are employed in equipment such as CT scanners, MRI machines, and robotic surgical systems. These connectors enable the rotation of critical components while ensuring uninterrupted power supply and data transmission, contributing to accurate diagnosis and precise medical procedures.

Advancements in Slip Ring Connector Technology

The evolution of slip ring connectors has seen significant technological advancements, enhancing their capabilities and performance. Some notable developments include:

Compact and Lightweight Design: Modern slip ring connectors are designed to be compact and lightweight, making them suitable for space-constrained applications. These miniaturized connectors maintain high functionality while occupying minimal space, allowing for flexible installation in various systems.

High-Speed Data Transmission: With the increasing demand for high-speed data transmission, slip ring connectors have evolved to support higher data rates. They can handle the transfer of large volumes of data, facilitating real-time communication, video streaming, and data-intensive applications.

Enhanced Durability and Reliability: Slip ring connectors are now built to withstand harsh environments, including extreme temperatures, humidity, and vibrations. With improved sealing, robust materials, and advanced engineering, these connectors ensure long-lasting performance and reliability, even in challenging operating conditions.

Slip ring connectors have transformed the landscape of electrical connectivity in rotating systems. Their ability to transmit power, signals, and data across rotating interfaces with utmost reliability and efficiency has made them indispensable in various industries. From robotics and wind energy to medical equipment and industrial machinery, slip ring connectors enable seamless electrical connectivity, unlocking new possibilities and enhancing system performance. As technology continues to advance, slip ring connectors will continue to play a pivotal role in powering the seamless connectivity of tomorrow.

See What We Can Do