The pursuit of renewable energy has led to remarkable advancements in wind power generation, with wind turbines standing tall as beacons of sustainable electricity production. Within these towering structures, slip ring connectors play a vital role in maximizing the efficiency and reliability of wind turbine systems. In this article, we explore how slip ring connectors have revolutionized wind turbines, enabling seamless power transmission, data communication, and enhanced performance. Join us as we uncover the untapped potential of slip ring connectors in the realm of wind energy.

Unleashing the Power of Wind Turbines

Wind turbines have emerged as an essential component of the global renewable energy landscape. These impressive structures harness the kinetic energy of the wind and convert it into electricity. However, to ensure optimal performance, the complex rotating systems within wind turbines require reliable and uninterrupted power transmission—enter slip ring connectors.

The Role of Slip Ring Connectors in Wind Turbines

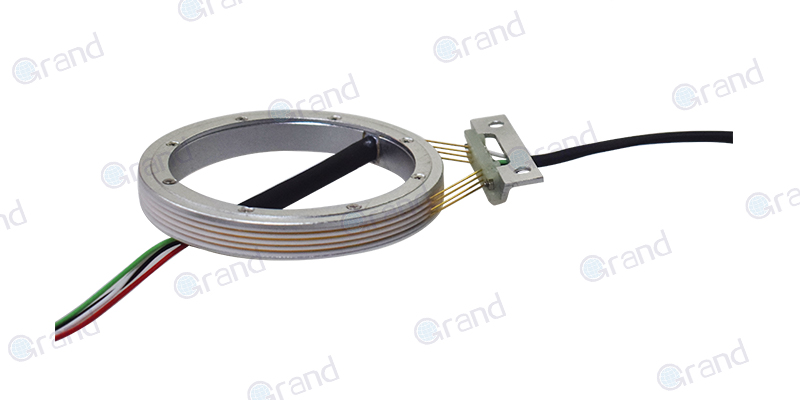

Slip ring connectors serve as the vital link between the stationary and rotating components within wind turbines. They facilitate the seamless transmission of electrical power, signals, and data, enabling efficient operation and control of various subsystems. By overcoming the limitations of traditional wiring methods, slip ring connectors have become indispensable in wind energy applications.

Power Transmission

Wind turbines rely on slip ring connectors to transmit electrical power from the generator located in the nacelle to the grid. As the turbine blades rotate, the slip ring connectors ensure a continuous electrical connection, allowing the generated power to be efficiently transferred from the rotating blades to the stationary components. This uninterrupted power transmission ensures a steady supply of electricity to the grid, contributing to a reliable and consistent renewable energy source.

Signal and Data Transmission

In addition to power transmission, slip ring connectors facilitate the exchange of signals and data within wind turbines. They enable the transmission of vital information from various sensors and control systems located on the rotating components to the stationary control room. This data includes wind speed, temperature, vibration, and other parameters crucial for monitoring and optimizing turbine performance. Slip ring connectors ensure accurate and real-time data communication, enabling efficient turbine control and maintenance.

Enhanced Efficiency and Reliability

The implementation of slip ring connectors in wind turbines brings several benefits that contribute to enhanced efficiency and reliability:

Reduced Maintenance Downtime: Slip ring connectors minimize the wear and tear associated with traditional wiring methods. By providing a continuous electrical pathway without the need for rotating cables, they significantly reduce maintenance downtime and associated costs.

Improved System Performance: Slip ring connectors enhance the overall performance of wind turbines by ensuring stable power transmission and reliable data communication. This contributes to efficient turbine operation, maximum power generation, and optimized energy output.

Adaptable Design: Slip ring connectors are designed to accommodate the specific requirements of wind turbine systems. They can handle high currents, voltages, and data rates while withstanding challenging environmental conditions, including temperature variations, vibrations, and humidity.

Modular and Scalable Solutions: Slip ring connectors offer modular and scalable solutions, allowing for easy installation, maintenance, and expansion of wind turbine systems. Their versatility enables seamless integration into various turbine designs and facilitates future upgrades or repairs.

Advancements in Slip Ring Connector Technology

To meet the evolving needs of the wind energy industry, slip ring connectors have undergone significant technological advancements:

Enhanced Conductive Materials: Slip ring connectors now employ advanced conductive materials, such as high-quality metals and alloys, to ensure efficient power transmission and signal integrity. These materials offer low resistance, high conductivity, and excellent wear resistance, ensuring long-term reliability.

Sealings and Environmental Protection: Modern slip ring connectors feature improved sealing techniques and robust designs to protect against harsh environmental conditions. They are equipped with seals and coatings to prevent dust, moisture, and contaminants from compromising performance and longevity.

Integrated Data Communication: Advanced slip ring connectors are equipped with integrated data communication capabilities, allowing for the transmission of high-speed data signals. This enables efficient monitoring, control, and diagnostics of wind turbine systems, enhancing operational efficiency and maintenance practices.

Slip ring connectors have emerged as indispensable components in the world of wind energy. By facilitating seamless power transmission and data communication within wind turbines, they contribute to enhanced efficiency, reliability, and performance. As the demand for renewable energy continues to grow, slip ring connectors will play a crucial role in unlocking the full potential of wind power, enabling a greener and more sustainable future.

See What We Can Do