In the realm of data transfer technology, there is one component that stands quietly crucial, bridging the connection between stationary and rotating parts—The slip Ring. Slip ring data transfer refers to the process of transmitting signals and power through an electromechanical device known as a ‘slip ring’. This device accomplishes the feat of maintaining an electrical connection or signal transmission between stationary and rotating systems, overcoming a traditionally significant challenge in electromechanical systems design.

Data transfer forms the backbone around which the modern world spins. Its relevance spans a vast spectrum, from simplistic domestic appliances to high-end scientific equipment, and industrial machinery to sophisticated communication systems. Industrially, the fields of aerospace, defense, energy, robotics, and automation, among others, heavily rely on the seamless transfer of data through different components of a system. The proficiency to transmit varied data forms—whether power, electric signals, or digital data—could determine the very success or failure of system functions.

Enter slip rings—an integral part of several electromechanical devices that operate continuously over prolonged periods. Slip rings allow for uninterrupted data transfer, solving the rotating connectivity problem. Enabling the transfer of power and data signals while a system component is in motion, slip rings outmaneuver the issue of twisting and tangling of wires in rotating assemblies. This unique attribute sets the basis for using slip rings in data transfer and makes them an essential component in diverse application scenarios, including wind turbines, cable reels, test rigs, rotary tables, and more.

In essence, the introduction and adoption of slip rings in the field of data transfer has been a game changer, successful in addressing a long-standing challenge in system design. Its proficiency in ensuring smooth and ceaseless transfer of power and signals amongst rotating and stationary parts, thereby enhances system reliability, efficiency, and life span. As we journey deeper into the world of digitization and automation, it’s clear that slip ring data transfer technology will continue to hold its ground as an irreplaceably essential cog in the machinery.

The Working Principle of Slip Ring for Data Transfer

Slip rings function based on a straightforward yet ingenious principle of maintaining electrical connectivity—particularly while transferring different types of data—between stationary and rotating parts of a system. Understanding the complex processes underlying the working of slip rings entails traversing through its three fundamental aspects:

How Slip Rings Work

At the core of a slip ring lies an assembly of conductive rings and contact brushes that form electrical connections. The conductive rings are mounted on a central shaft that rotates along with the system, while the contact brushes remain stationary, in a fixed position. These brushes, typically made of metal or graphite, are in continual contact with the conductive rings, sliding over the rings as they rotate.

Electrical signals and power are transmitted from the stationary component (parent structure) to the rotating part (rotor) through these brushes and conductive rings. This dynamic and unbroken connection ensures that systems function uninterruptedly, without the risk of wire entanglement or twisted cables.

Data Transfer Process Through Slip Rings

The process of data transfer through slip rings relies upon the consistent contact between the brushes and the conductive rings. When a data signal or power from the stationary component is fed into the contact brushes, it is conveyed to the rotating component via the sliding action of the brushes on the conductive rings. Conversely, data generated from the rotating component is also transmitted back to the stationary structure through the same brush-ring interface.

As contact brushes maintain continuous—albeit sliding—contact with conductive rings, they ensure seamless transmission of data signals to and from the rotating system parts without any disruption or distortion.

Types of Data Transfer in Slip Rings

Slip rings are versatile—they facilitate the transfer of diverse data types, including both analog and digital signals. Analog signals, transmitted as continuous waves, are generally employed for transferring sensor data, audio, or video information. In contrast, digital signals, transmitted as discrete binary values, are used for more complex data communication and control systems.

Thanks to advancements in slip ring technology, the device is now capable of carrying out high-precision data transfer for high-speed communication protocols, such as Ethernet, USB, and other RF signals. The unification of power, analog, and digital signal transmission in a single slip ring assembly has empowered manifold systems to operate seamlessly in different industries involving varying degrees of complexity.

In summary, slip rings are pivotal in managing data exchange between stationary and rotating components of a system. Their simplistic but highly efficient working mechanism enables them to host an array of data types, ranging from analog signals to digital data, fostering their usage in a plethora of industrial and scientific applications.

Different Types of Slip Rings Used in Data Transfer

Wrapped in an illustrious range of design variances, slip rings manifest in several types, each bringing distinct attributes and fitting into unique use cases. Delving into these diverse slip ring types allows us to appreciate their respective structures, working principles, and potential applications.

Capsule Slip Rings

Capsule slip rings, as the term implies, feature a compact, capsule-like structure designed to save space. They come in a range of diameters and lengths, providing a target solution where size and weight constraints exist. These slip rings often include gold-to-gold contacts for low electrical noise and longer operational lives. They are extensively used in closed-circuit cameras, robotics, medical equipment, an array of light industrial machinery, and other applications that demand compact size and reliable performance.

Through-Bore Slip Rings

Through-bore slip rings, often called hollow shaft slip rings, are distinguished by the hollow center or ‘through-bore’. They feature larger diameters, with the central bore generally used to mount additional equipment such as pneumatic or hydraulic rotary joints. The advantage lies in their ability to integrate more circuits and handle multiple signal types. Used predominantly in heavy engineering machinery, wind turbines, medical CT machines, and rotating display booths, through-bore slip rings offer robust and flexible solutions for complex engineering requirements.

Pancake Slip Rings

Characterized by their flat, disk-like form factor (hence the term ‘pancake’), these slip rings are the go-to choice for systems with limited axial length or height restrictions. With a compact vertical dimension and typically larger diameters, pancake slip rings are essential for space-constrained applications. Despite their compact form factor, they come in a variety of configurations to accommodate a wide range of power and signal transmissions. They find applications in filling machines, cable reels, printing presses, and rotary tables.

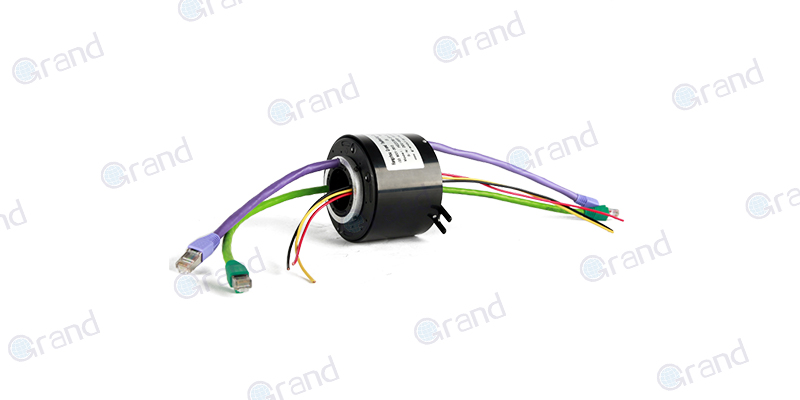

Ethernet Slip Rings

With the advent of high-speed data communication, Ethernet slip rings have emerged as a popular choice. These slip rings are designed to transmit Ethernet protocols across rotating interfaces. Engineered with high-precision inner structure and specific shielding measures, they ensure minimum data packet loss and preserve signal integrity even at high resolutions. They are used extensively in high-speed surveillance systems, wind turbines, data communication systems, and automated production lines.

Fiber Optic Rotary Joints (FORJ)

FORJs—standing at the forefront of modern slip ring technology—provide the ability to transfer optic signals across rotatory interfaces. They are indispensable for high-speed data transmission over long distances with almost zero signal loss. These rotary joints are immune to electromagnetic interference and are seen in radar systems, cable TV studios, offshore communication systems, and underwater robotic systems.

Taking into account the distinctive features and application scenarios of each type of slip ring underscores the versatility of this seemingly simple component. Whether it’s about making allowances for compact spaces, enabling high-speed data transfer, or facilitating complex machinery integration, the different types of slip rings continue to cater to varying industry needs and preferences. As a result, slip rings find application in nearly every industry that uses system components with relative rotational and stationary parts.

Applications of Slip Ring Data Transfer

The unique ability of slip rings to maintain electrical connectivity between moving and stationary components has led to their widespread adoption in numerous fields and applications. From the depths of the ocean to the boundless expanse of outer space, slip rings are industriously at work, ensuring seamless data transfer.

Mars Rovers, Drones, Security Systems, Wind Turbines, and More

In Mars Rovers, slip rings come into play by allowing the rovers to rotate their scientific instruments and move their wheels while maintaining continuous electrical connections. They are critically important to successful data transfer from these instruments back to Earth.

Drones harness the convenience of slip rings primarily in their gimbal systems, which need to rotate freely to adjust camera angles. Utilizing slip rings helps achieve unrestricted 360-degree rotation without signal loss or line twisting.

In security systems, particularly in surveillance cameras, slip rings enable continuous 360-degree rotation while transmitting video signals and power. This results in non-stop, real-time monitoring and enhanced system reliability.

In the domain of renewable energy, wind turbines stand as a shining example of slip ring application. As turbine blades rotate to capture wind energy, slip rings enable the transmission of generated electrical power and data signals from the rotating nacelle to the stationary grid system.

Benefits of Slip Rings in Different Sectors

The benefits brought forth by slip ring technology are widely appreciated across various industries. Firstly, they facilitate uninterrupted power and data transmission between rotating and stationary system components, thereby enhancing system reliability and operational lifespan. This plays a crucial role in sectors like wind energy, aerospace, defense, medical, and heavy machinery where system failure can lead to enormous costs or even catastrophic effects.

Secondly, by averting cable entanglement during system rotations, slip rings offer operational safety and largely eliminate the need for system maintenance related to cable damage. Lastly, slip rings, especially Ethernet Slip Rings and Fiber Optic Rotary Joints, allow high-speed data transfer across rotary interfaces, making them quintessential in modern digital communication systems and data-intensive applications.

Future Applications and Technologies

As we venture into the future, it is anticipated that slip ring data transfer technology will find broader applications in more advanced forms of technology. For example, in the realm of aerospace science, data transfer systems for more advanced planetary rovers, space stations, and satellites might heavily rely on improved versions of slip rings.

In the unfolding era of Industry 4.0, where automation and robotics define manufacturing, slip rings will likely play a pivotal role in providing consistent power and maintaining data exchange among moving parts. Furthermore, as the geophysical exploration and renewable energy sectors grow, the need for sophisticated slip rings capable of performing under harsh conditions and ensuring high-speed data transfer will increase substantially.

In essence, the expansive application of slip rings in facilitating data transfer underlines their indispensable value to a myriad of industries. As technology continues to evolve and new frontiers are navigated, the role of slip rings as a connectivity enabler is bound to strengthen, marking a promising future for this dynamic technology.

Slip Ring Data Transfer: Technical Specifications

The perfect slip ring solution relies on a proper understanding of the technical specifications tying into its performance and reliability. Several key attributes must be considered when selecting slip rings for effective data transfer. Additionally, it is important to comprehend how environmental factors and the aging process can impact a slip ring’s performance.

Key Attributes and Selection Criteria for Slip Rings Used in Data Transfer

While choosing slip rings for specific data transfer applications, several criteria and characteristics should be taken into account:

- Bandwidth: The bandwidth is a measure of the data-carrying capacity of a slip ring. Higher bandwidth specifications are necessary for systems requiring the transfer of substantial data, such as high-definition video or complex control signals.

- Rotational Speed: Each slip ring exhibits a maximum rotational speed, measured in revolutions per minute (RPM). The chosen slip ring RPM rating must meet or exceed the system’s rotational speed requirement.

- Data Rate: Slip rings supporting high-speed digital signals should comply with protocol-specific data rates (i.e., Ethernet, USB, etc.) that match or surpass the necessary throughput for seamless data exchange.

- Number of Circuits: The required number of circuits depends on the signals and power lines that need to be transferred through the slip ring. Factors such as voltage levels, current capacity, and the type of signals (digital or analog) are essential considerations.

- Contact Material: The choice of contact material between the brush and conductive ring plays a vital role in a slip ring’s performance. Noble metals such as gold offer low electrical noise and prolonged operational life. However, these metals are less suitable for high-power applications.

The Role of Electrical Noise and its Effects on Data Transfer

Electrical noise, generated by the sliding action between brushes and conductive rings, can cause distortions in the transmitted data signals. This noise potentially degrades data integrity and reduces system reliability. To minimize electrical noise, proper choice of contact materials—such as gold-to-gold contacts—is essential. Moreover, advanced engineering practices that incorporate shielding and noise reduction techniques can be deployed to ensure optimal slip ring performance.

How Environment and Longevity Affect Slip Ring Performance

Environmental factors such as temperature and humidity can notably impact the performance and lifespan of slip rings.

- Temperature: Slip rings should operate within their specified temperature range to ensure consistent performance. Exposure to extreme temperatures, especially for extended periods, can lead to material degradation, contact wear, and increased electrical noise.

- Humidity: High humidity may cause corrosion and degradation of contact materials, accelerating wear and compromising the overall operation of the slip ring. Therefore, choosing slip rings with corrosion-resistant coating and protection from moisture ingress is crucial when operating in damp environments.

In terms of longevity, the wear of contact materials and brushes over time directly affects the slip ring’s performance. As the level of wear increases, electrical noise may rise due to inconsistent contact, resulting in signal degradation and reduced reliability. Regular maintenance and inspection play a crucial role in mitigating this issue and prolonging the slip ring’s operational life.

To sum up, considering the key attributes and technical specifications of slip rings alongside the environmental influences and their aging is imperative. Detailed planning ensures optimal performance and long-lasting reliability of the chosen slip ring, catering to the specific data transfer requirements of diverse applications.

Slip Ring Data Transfer: Common Concerns and Quality Assurance

As fundamental as slip rings are to a host of applications, there are indeed associated concerns and challenges to consider. Understanding these, manufacturers intensively focus on quality assurance while progressively seeking technological advancements to mitigate such issues.

Common User Concerns

Users generally exhibit concerns over factors that could potentially compromise the efficiency and longevity of slip ring systems:

- Data Loss or Corruption: Among the primary concerns is data loss or corruption during transmission. This could be a consequence of electrical noise, line interference, or contact wear, leading to hindrances in achieving flawless data communication.

- Wear and Tear: The mechanical nature of slip rings, with their rotating parts, leads to inevitable wear and tear. As the contact materials wear off, there may be challenges in maintaining signal integrity and electrical performance.

- Maintenance Requirements: Regular maintenance is crucial to preserve the optimal performance and lifespan of slip rings, especially in high-bandwidth data transfer applications. Consequently, the workmanship and time associated with this upkeep could be a matter of unease for users.

- Environmental Resilience: Lastly, users might apprehend the effects of adverse environmental conditions, such as extreme temperatures, humidity, and vibration, on the performance and lifespan of the slip rings.

Steps Manufacturers Take to Ensure Quality and Reliability

To alleviate these concerns and ensure high-performance, reliable slip rings, manufacturers meticulously adopt a series of measures:

- Quality Material Selection: By choosing high-grade contact materials, manufacturers enhance the slip ring’s durability, minimize electrical noise, and maximize data integrity. Noble metals, for instance, are often used for their low electrical noise and high corrosion resistance.

- Thorough Testing: Rigorous in-house testing often includes life-cycle testing, bandwidth testing, environmental stress tests, vibration, and shock tests. These tests validate the slip ring’s reliability, longevity, and performance under varying conditions.

- Tailor-made Design: By customizing design specifications, such as the number of circuits, data rate, and rotational speed, manufacturers can precisely cater to the application’s needs.

- Stringent Manufacturing Standards: Adherence to internationally recognized manufacturing standards and the implementation of Quality Management Systems (ISO 9001, for example) demonstrate the manufacturer’s commitment to product quality and reliability.

Advancements Made to Tackle Common Issues

Technological advancements continue to combat common concerns, dramatically improving the overall performance and reliability of slip rings:

- Advanced Contact Materials and Techniques: The introduction of noble metals (like gold) for brush-and-ring interaction substantially reduced electrical noise. Innovations in brush design have also led to less wear and longer life-cycle.

- Utilization of Shielding Techniques: To minimize interference from the surrounding electronics and enhance signal integrity, shielding techniques have been introduced to slip ring assemblies.

- Sealed and Encapsulated Designs: To combat environmental damage, sealed and encapsulated slip rings have been developed that offer resistance against moisture, dust, and other potentially harmful substances. These designs increase the resilience and lifespan of the rings.

Through these measures and advancements, slip ring manufacturers have made substantial strides in assuaging user apprehensions and providing durable, reliable, and high-performance solutions for effective data transfer across a wide array of applications. As technology further evolves, it’s expected that the slip ring technology will continue to match strides, addressing emerging application requirements, and pioneering innovative solutions.

Slip Ring Data Transfer: Cost Analysis

Understanding the cost-effectiveness of slip rings facilitates informed decision-making processes. The cost can vary significantly depending on several attributes. Moreover, when compared with alternative data transmission methods, slip rings often present a viable and financially sound choice, especially for specific applications and environments.

Factors Affecting the Cost of Slip Rings

Several factors influence the overall cost of slip rings:

- Material Quality: The use of advanced, high-grade materials, especially for the contact interface, like gold or silver, can add to the cost. However, these materials offer extended longevity, reduced maintenance, and excellent signal integrity, providing value for the extra cost over time.

- Number of Circuits: The complexity of the slip ring, defined by the number of circuits it contains, plays a major role in the pricing. More circuits translate to a more complex, and thus, more expensive product.

- Data Transmission Rate: High-speed data transmission requires slip rings with superior electrical characteristics and more intricate design. As a result, slip rings with higher data rates tend to come at a higher cost.

- Rotational Speed: Slip rings capable of maintaining connectivity at high rotational speeds are made to stringent specification standards, which makes them more expensive.

- Specific Customizations: Any tailor-made adjustments to the design or special add-ons to meet specific system requirements can also increase the cost.

Comparative Analysis with Other Data Transfer Methods in Terms of Cost

When comparing the cost of slip rings with alternative data transfer methods, several aspects should be considered:

- Cabled Systems: Systems using cables for data transfer generally have lower initial acquisition costs compared to slip rings. However, over time, cable maintenance, replacement costs due to wear and tear, and system downtime from cable entanglement can make slip rings more cost-effective.

- Wireless Systems: Though wireless systems eliminate mechanical wear and the need for physical connections, they can be prone to signal interference, data latency, and security risks, which may lead to potential operation costs. Furthermore, they are often less viable for high-data-rate or sensitive communication. Slip rings, on the other hand, offer robust and secure physical connections ideal for real-time, high-speed data transfer.

- Optical Rotary Joints (ORJs): ORJs offer high-speed data transfer with low electrical noise but come with a significantly high cost due to their complex assembly and advanced materials. Also, their applications are limited by their delicacy and susceptibility to environmental conditions.

In summary, while slip rings might entail a higher initial cost, their prolonged lifespan, reduced maintenance needs, and the ability to maintain superior data integrity often make them a cost-efficient choice. The comparison of costs, therefore, should be considered from a comprehensive, long-term perspective, balancing the upfront cost against long-term value, reliability, and maintenance expenses.

Conclusion

As this exploration into slip ring data transfer manifests, its role in facilitating seamless system communication is unparalleled. Despite user concerns, continuous advancements are addressing potential challenges, promising exciting future developments. Ultimately, the value of understanding this technology cannot be underestimated, especially in a world revolving around data-driven realizations.

See What We Can Do