Defining slip ring grease in the realm of electrical mechanics involves understanding its pivotal role as a lubricating agent. The grease reduces friction and wear between brushes and slip rings, amplifying their operational performance and extending their lifespan. It works silently behind the scenes, maintaining smooth electrical signal transmissions, and ultimately ensuring the efficiency of the system as a whole.

However, the importance of slip ring grease extends far beyond its fundamental role. It constitutes a significant element impacting the overall efficiency and longevity of slip ring assemblies. Despite its apparently humble part, slip ring grease carries significant responsibility for the optimal functioning of complex electrical systems, which is particularly evident in high-demand industries such as wind energy, manufacturing, and telecommunications.

An overview of the article provides a glimpse into the in-depth exploration of this key component. Starting with an insight into its role, the article delves into an assortment of slip ring grease types, each with unique properties and specific applications. Subsequently, we address common user concerns related to slip ring grease, including ideal selection and application challenges.

The article also ventures into the guidance for choosing the right slip ring grease based on multiple factors and best practices for its application. We will highlight and answer the frequently asked questions about slip ring grease to dispel confusion and improve user understanding. The material concludes by looking into the future and discussing innovative trends and advancements in the domain of slip ring grease.

Given the overarching role this single component plays in slip ring performance and longevity, it’s clear that understanding slip ring grease is vital for anyone vested in the smooth operation and maintenance of these systems. This article will serve as an all-encompassing guide, shining a light on this unsung hero of slip ring assemblies.

The Role of Slip Ring Grease

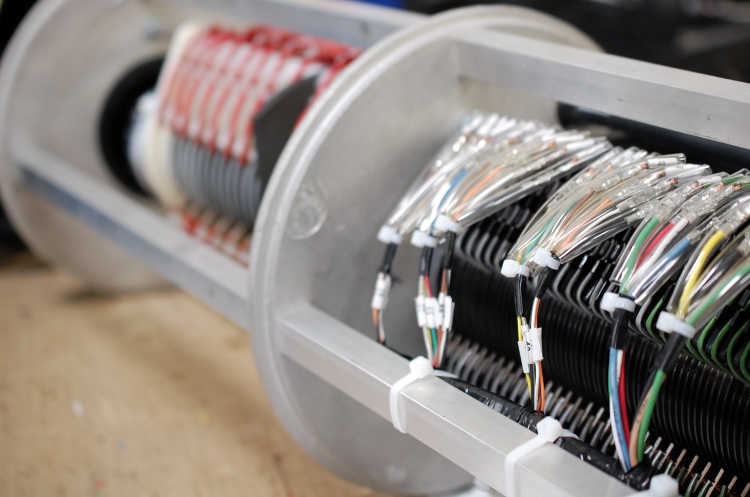

To fully appreciate the role of slip ring grease, we first need to understand its principal functionality within the context of a slip ring assembly. The primary role of slip ring grease is to assist in reducing friction and wear, which it achieves by creating a lubricating barrier between brushes and slip rings. In effect, it serves the critical purpose of a smooth operator, ensuring the unhampered flow of electrical signals as the brushes sweep over the slip rings.

This resulting minimization of friction is a significant factor in reducing wear and tear. Without this protective layer of grease, the continuous movement between brushes and slip rings would cause accelerated wear, disrupting the electrical signal transmission and deteriorating the overall operational efficiency. Thus, adequate and appropriate greasing is about more than simply ensuring a smooth run; it directly links to the level of wear and tear the slip ring assembly can endure, and, eventually, its operational lifespan.

Moreover, exploring its impact on performance and longevity gives further insight into the substantial influence of slip ring grease. Properly lubricated slip rings are less prone to overheating, allowing for a more efficient transmission of electrical signals. This translates into better and more reliable performance. But it doesn’t stop there. By preventing excessive physical wear and protecting against potential corruption caused by environmental contaminants, the right grease application can substantially extend the useful life of slip rings.

Consequently, regardless of the operating conditions or specific application, the correct use of slip ring grease is an indispensable maintenance practice. Not only does it optimize performance levels, but it also equips the slip ring assembly for a long, productive service life, demonstrating the profound impact of slip ring grease on the efficiency and longevity of the entire system.

Types of Slip Ring Grease

Slip ring grease is not a ‘one-size-fits-all’ proposition. There exist various types, each exhibiting different properties tailored to specific applications and environmental conditions. Every grease type has been engineered to provide optimal performance under certain conditions. For instance, some greases are designed for high-speed applications, others for high or low-temperature environments, or even for operations where heavy loads are prevalent.

To provide a detailed understanding, we begin with a broad categorization based on specific applications. Application-based types might comprise high-speed grease, high-load grease, or high-temperature grease. High-speed grease has special additives to handle quick rotational movement. In contrast, high-load greases include extreme pressure additives to absorb shock loads effectively. High-temperature grease, designed to withstand extreme heat, prevents premature breakdown and ensures smooth functioning.

Similarly, environmental considerations play a critical role in the type of grease used. For instance, marine or underwater applications may necessitate water-resistant or corrosion-inhibiting greases. Similarly, other environmental considerations might include exposure to dust, which may require dust-tolerant greases.

Delving deeper into their distinct properties, it’s crucial to note how each variant’s composition determines its suitability for varying operational conditions. For instance, silicone-based greases offer excellent resistance to a broad temperature range and environmental contaminants, making them ideal for harsh climates. In contrast, petroleum-based greases may provide better performance in high-speed or high-load situations due to their superior lubricating properties.

In essence, every type of slip ring grease brings its unique strengths to address the demands of different operating conditions. By choosing the right grease, users can optimize performance, combat specific environmental challenges, and extend the lifespan of their slip ring assemblies. The vast array of slip ring greases available today underscores the importance of making an informed choice – one that aligns best with specific operational demands and environmental considerations.

Users’ Common Concerns About Slip Ring Grease

A myriad of questions and concerns can plague users when it comes to slip ring grease application. Shared anxieties tend to revolve around common themes, such as selecting the correct grease, determining an ideal re-greasing schedule, and understanding the consequences of over-greasing or under-greasing. Each of these challenges carries significant implications for the performance and longevity of the slip ring assembly.

Choosing the correct grease is a pivotal first step that often stumps users. This mainly stems from the vast array of grease types available, each tailored to a specific application or environmental condition. Selecting an inappropriate grease type can result in suboptimal performance and lead to increased wear and tear on the slip ring assembly, negatively impacting its lifespan. It’s essential to consider factors like operating temperature, rotational speed, load, environmental contaminants, and the specific material characteristics of the slip ring and brush while making a selection.

Determining a proper re-greasing schedule poses another common concern. Over-greasing can lead to excess grease being sloughed off, potentially contaminating other areas and causing a variety of failures. Conversely, under-greasing can result in increased friction, accelerated wear, and a consequent reduction in the efficiency and lifespan of the assembly.

Incorrect application of grease can yield problems like performance declines and component damage. For instance, inconsistencies in the application can create hot spots, leading to localized overheating. Similarly, the use of too much grease can cause churning, a situation where the slip ring spins in a sea of grease, causing high operating temperatures and potentially leading to grease degradation.

In a nutshell, the effective handling of slip ring grease can serve as both an opportunity and a challenge. Though it can be daunting to navigate these complexities, addressing these common concerns will go a long way in improving performance, minimizing unexpected downtime, and extending the life of slip ring assemblies. By knowing what pitfalls to avoid and best practices to embrace, users can harness the power of slip ring grease to enhance overall system efficiency and longevity.

Choosing the Right Slip Ring Grease

Identifying the correct slip ring grease is crucial in maximizing operation efficiency and longevity. This section aims to equip users with the necessary knowledge to make an informed decision, taking into account factors including the slip ring materials, operational temperatures, and the prevailing environmental conditions.

In terms of slip ring materials, not every grease is suitable for every type of slip ring or brush material. Using incompatible grease can cause brush wear or instability and deteriorate the slip ring surface. It’s advisable to consult the manufacturer’s recommendations or the advice of a lubricant specialist to ensure compatibility.

Taking into account operational temperatures is also vital. For environments with high temperatures, grease with a higher dropping point and temperature stability is required. On the other hand, if operations take place in low temperatures, grease with low-temperature fluidity is necessary.

Keep in mind that these criteria apply as much to industrial contexts as they do to home-based applications. Whether it’s a slip ring in a wind turbine or an electrical rotary joint in a home satellite dish, the principles remain largely the same. Compatibility, operational temperatures, and environmental conditions should drive the decision-making process.

Environmental conditions should also factor into the choice of slip ring grease. For example, if the slip ring operates in a damp or wet environment, water-resistant grease is necessary. Conversely, in an environment laden with dust or other foreign particles, grease with exceptional sealing properties is a more suitable choice.

The choice of slip ring grease should never be an afterthought. Instead, it should be the result of a careful examination of technical specifications, operational scenarios, and environmental factors. Taking these key considerations into account can markedly improve the performance, lifespan, and reliability of slip ring assemblies, regardless of their unique operational contexts and application areas.

Best Practices for Applying Slip Ring Grease

Proper maintenance, particularly the correct application of slip ring grease, is paramount in ensuring smooth operation and extended service life of slip ring assemblies. This section focuses on regular maintenance procedures and provides a step-by-step guide for applying grease, with emphasis on essential safety measures.

Regular Maintenance Procedures

Before diving into the application of grease, it’s important to establish a regular maintenance schedule. This routine should include the inspection and cleaning of slip rings and brushes, and assessing their condition for wear and tear. Depending on the operating environment, contamination, and usage levels, grease re-application intervals may vary. Consult the manufacturer’s guidelines for a recommended maintenance schedule.

Step-by-Step Guide to Applying Slip Ring Grease

- Safety First: Disconnect power to the slip ring assembly and follow appropriate lockout/tagout procedures. Wear suitable protective gear, including gloves and safety glasses, and ensure that the workspace is well-ventilated.

- Clean the Slip Rings and Brushes: Using a soft, lint-free cloth, gently clean the surfaces of both the slip rings and brushes to remove dirt, dust, and any residual grease. Avoid the use of abrasive materials that may damage these surfaces. For stubborn deposits, use a specialized electrical contact cleaner, ensuring that the surfaces are dry before proceeding.

- Inspect for Damage: Examine the slip rings and brushes for signs of wear, pitting, or excessive corrosion. Replace damaged components as needed to maintain optimal performance.

- Apply Grease: Decide on the appropriate grease, based on compatibility and application requirements. Utilize the recommended application methods, such as brush-on or aerosol grease. Apply an even, thin layer of grease to the slip ring surfaces, avoiding over-application, which can cause churning and contamination.

- Safety Measures: After completing the grease application, carefully remove protective gear, clean tools, and equipment, and dispose of waste materials per applicable regulations. Store grease containers in a cool, dry place away from potential sources of contamination.

By adhering to these best practices in the application of slip ring grease, users can maintain optimal performance and significantly extend the lifespan of the slip ring assemblies. Ultimately, a proactive and informed approach to maintenance procedures will greatly reduce unexpected downtime and minimize operational expenditure.

Innovations and Future Trends in Slip Ring Grease

With growing technological advancements, the field of slip ring lubrication is continually evolving. This section explores cutting-edge products, and advanced grease formulations offering enhanced performance, and provides insights into future trends, potential challenges, and the sustainability shift within the industry.

Novel Products and Advanced Grease Formulations

New product development and reformulation of existing products are ongoing in the slip ring lubrication realm. The focus is majorly on creating innovative grease types that offer enhanced performance including improved conductivity, reduced wear, and extended operating temperature ranges.

The recent development and use of synthetic greases offer numerous benefits such as better viscosity-temperature behavior, reduced friction, and overall enhanced mechanical stability. These specialized greases demonstrate high resistivity against oxidization and degradation, ensuring longer operational lifespan and increased intervals between reapplications.

Future Growth Prospects and Potential Challenges

Slip ring applications are becoming increasingly complex, demanding improvements in surface technology, materials, and lubrication. As industries like renewable energy and space exploration continue to grow, the demand for robust and efficient slip ring solutions is expected to rise.

However, the industry also faces challenges, such as designing greases that can withstand special conditions, like extreme temperatures or aggressive substances, in different industrial sectors. These hurdles prompt constant research and innovation to devise solutions that meet these specific needs.

Shift Towards Eco-friendly Lubrication Solutions

With rising awareness and regulations around environmental impact, there’s a growing trend towards eco-friendly lubrication solutions. Biodegradable greases align with this shift, offering an environmentally friendly alternative without compromising on essential properties like load-carrying ability, resistance to oxidation, and corrosion protection.

In the coming years, the industry’s focus on sustainability is likely to intensify, further driving the development and adoption of these eco-conscious lubrication solutions across various sectors.

The advancements in the field of slip ring lubrication, despite potential challenges, signify a promising future. With careful attention to the prevailing industry trends and an understanding of future directions, users can make informed decisions that deliver both operational efficiencies and environmental benefits.

Conclusion

By offering a more intricate understanding of slip ring grease usage, this comprehensive guide accentuates its crucial role in maintaining smooth and efficient slip ring operations. Remember, the proper selection and application of slip ring grease can spell the difference between a well-functioning system and one that’s hobbled by frequent issues. Stay tuned with us for more such insights.

FAQs About Slip Ring Grease

When it comes to slip ring grease, users often grapple with a wide array of queries and concerns. These relate not just to the choice of slip ring grease, but also to its application and maintenance. To aid users, our responses—based on best practices and expert insights—attempt to address these recurring questions.

Q: How do I choose the right slip ring grease?

A: Selecting the appropriate slip ring grease necessitates consideration of various factors such as slip ring material, operational temperature range, and prevailing environmental conditions. If operating in a Q&A format, elaborate on each of these parameters. Reference manufacturers’ guidelines or consult a lubricant specialist for precise, application-specific advice.

Q: How often should I re-grease my slip ring?

A: The frequency of re-greasing depends heavily on operational factors, environmental conditions, and the inherent condition of the slip ring assembly. High load, high speed, high operating temperature, and severe environmental conditions can increase the need for more frequent greasing. Always refer to the manufacturer’s recommendations for a maintenance schedule tailored to your specific application.

Q: What’s the harm in over-greasing or under-greasing my slip ring?

A: Over-greasing can cause excess grease to be ejected from the slip ring, potentially contaminating other components and leading to failures. Under-greasing, on the other hand, increases friction and accelerates wear, impacting efficiency and shortening the lifespan of the assembly.

Q: Can I mix two different types of slip ring grease?

A: Generally, mixing two or more different types of greases is not recommended. Different grease types have distinct properties and combining them can alter these properties, potentially leading to performance issues or even damage to the slip ring assembly. Always consult manufacturers’ guidelines or a lubricant specialist before considering mixing greases.