Introduction

For anyone interacting with machinery or technology involving rotation, a basic understanding of the elements at play can substantially improve operational efficiency. Among many such components, one hushed hero is the Slip Ring Harness (SRH). Enabling smooth and unhindered transmission of electrical power and signals between stationary and rotating sections, this device holds quite an intriguing story of its importance and application in various industries.

In our comprehensive guide, we’ll unveil all you need to know about Slip Ring Harnesses. Starting with a deeper look into what an SRH is, we’ll traverse through its various components, working mechanisms, installation processes, benefits, and maintenance tips. Moreover, we’ll touch upon its real-world applications, providing you with a holistic understanding of this indispensable device.

So, whether you are a professional looking to upgrade your knowledge, or a curious novice wanting to learn more about this remarkable device, this comprehensive guide is designed just for you. Buckle up as we journey through the world of Slip Ring Harnesses!

What is a Slip Ring Harness?

As we navigate through our understanding of various instruments and components that shape the technology and machinery around us, the Slip Ring Harness (SRH) stands out as a remarkable yet often underrated device. While it may seem like a simple name, an SRH plays a significant role in ensuring seamless operations of numerous equipment, particularly those that involve rotation. To better understand the uniqueness and importance of this device, we need to focus on two pivotal aspects – its definition and importance.

Definition of Slip Ring Harness

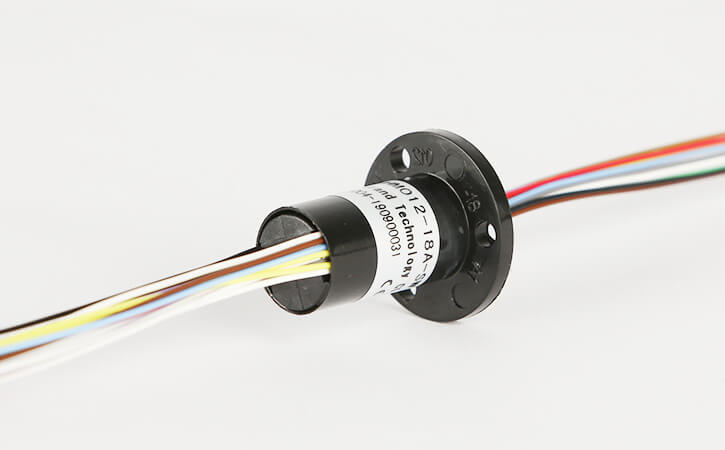

A Slip Ring Harness, often simply referred to as a “slip ring,” is a sophisticated and carefully designed component that enables the transmission of electrical power, data, and signals between a stationary source and a part that rotates around a single axis. The beauty of its design and function lies in its ability to ensure uninterrupted electrical connections while containing the rotational mechanism within its structure, preventing any obstruction or interference in the transmission process.

Slip rings come in various designs and sizes, depending on their purpose. Each design is crafted to serve specific machines or systems, making them highly adaptable to diverse industries and applications. Despite these variations, the core principle of a Slip Ring Harness remains the same – bridging an electrical connection between stationary and rotating entities, enabling a smooth transmission of power, data, or signals while navigating rotational movement.

Importance of Slip Ring Harness

Understanding the importance of Slip Ring Harnesses requires one to recognize the challenges posed by rotational motion in electrical systems. Imagine a system where power or data transmission is constantly disrupted due to tangled wires or disconnected circuits caused by rotation. The inefficiency and inconsistency in power or signal flow would be a massive hindrance, hampering the overall system performance.

That’s where an SRH comes in as the unsung hero of efficiency, enabling uninterrupted electrical connections between stationary and rotating parts, checking the box of both functionality and efficiency.

Moreover, SRHs have found their way into a multitude of applications, from the wind energy sector where they enable the rotation of massive turbine blades, to defense systems where they facilitate unbroken communication flows. Medical imaging, the automotive industry, and telecommunication systems – the scope of SRH applications is expansive and significant.

Above all, an SRH sets the foundation for rotational systems to work efficiently, managing the pivotal task of maintaining a consistent connection amidst constant movement. In doing so, it effectively ensures the system’s reliability, thus highlighting its importance as a vital cog in the machinery.

Slip Ring Harness Components

Every component of a Slip Ring Harness (SRH) plays a crucial role in maintaining the system’s seamless operation. From acting as a conduit for electrical transmission to ensuring power and signal integrity during rotation, each part

Let’s delve into each component of the SRH to better understand its full function and effect within the system.

Rotor

The rotor is the part of the SRH that connects directly to the rotating system. It’s built to withstand rotation while maintaining stable electrical contact. Electricity or signals pass from or to the rotor, depending on whether it’s functioning to transmit or receive.

Stator

The stator, or the stationary part, is attached to the power or data source and remains in a fixed position. It connects to the system or equipment that needs electrical power or needs to send or receive signals.

Brushes and Rings

These are the key players responsible for the actual transmission process. Brushes are soft metal strips or wires that maintain contact with the rotor and stator, keeping the electrical connection intact even when the rotor spins. The rings are attached around the rotor and are made from conductive material for optimal transmission.

Bearings

Bearings are an essential part of the SRH as they facilitate the smooth rotation of the rotor. They are built to reduce friction between the rotating and stationary elements of the system, allowing the rotor to spin freely around its axis.

Housing

The housing is what contains and protects all of these interior components. It’s typically constructed of robust material designed to withstand environmental factors and mechanical wear and tear.

It’s only when these components work together harmoniously that the SRH can perform its intended function efficiently. Understanding each component contributes to a comprehensive knowledge of the Slip Ring Harness and its operation, putting you one step closer to mastering this nifty device.

Absolutely, let’s dive into the functioning of a Slip Ring Harness.

How Slip Ring Harness Works

Understanding the function of a Slip Ring Harness (SRH) involves comprehending the interaction between its various components to facilitate power or signal transmission amidst a rotational scenario. Despite the changing orientation, the SRH eliminates the worry of tangled wires or interrupted transmissions. Let’s break down its working process.

Step 1: Establishing Connections

Firstly, the Slip Ring Harness needs to be connected properly to the system. The rotor is attached to the rotational part of the system that requires power or signals, while the stator is fixed to the stationary source or receiver of electricity or data.

Step 2: Powering Up

As the system powers up, electricity or signals are fed into the SRH. If the stator is connected to the power or signal source, it receives the input and transfers it internally through the brushes that are in contact with the rotating rings.

Step 3: Transmission

The brushes, maintaining contact with the rings, help convey the electricity or signals into the rotor as they slide over its surface. Because the brushes are designed to maintain their connection with the rings even during rotation, the transmission remains unhindered when the rotor starts to spin.

Step 4: Reception

The power or signal then reaches the connected rotational machinery or system through the rotor, enabling its operation. In the case where signals or data are sent from the rotating part, the process is reversed, with the rotor capturing the signals and transferring them back through the brushes and rings to the stator.

Step 5: Repeat

With every rotation, this process is repeated, ensuring a continuous and stable transmission of power or signals, regardless of the continuous movement.

In essence, an SRH works by exploiting the essential elements of rotational mechanics and electronics, incorporating brushes and conductive rings to sustain an electrical connection. Understanding its working mechanism allows for efficient handling and troubleshooting, enhancing overall operational performance and system longevity.

Certainly, let’s delve into the process of installing a Slip Ring Harness.

Installation of Slip Ring Harness

Installing a Slip Ring Harness (SRH) involves attaching it to the appropriate segments of a system where rotation is a prime factor and an uninterrupted electrical or data flow is required. To ensure the slip ring harness operates efficiently and safely, one needs to follow a methodical installation process. Before we delve into the step-by-step installation guide, let’s first understand which tools are essential for this procedure.

Tools Required

Before beginning the installation process, it’s important to assemble the necessary tools. Typically, these include:

- Screwdriver Set: You’ll need this to secure the SRH in place within the system. Ensure you have a set of different sizes to accommodate varying screw head sizes.

- Wire Strippers: These will be handy if wire adjustments are needed during the installation.

- Multimeter: Employed to check electrical connections after installation, ensuring proper functioning.

- Wrench or Pliers: These are mainly used to tighten or loosen nuts or bolts within the installation setup.

Ensure you are equipped with Personal Protective Equipment (PPE) such as gloves and safety glasses to protect against potential hazards during installation.

Step-by-Step Installation Guide

Step 1: Assess and Prepare

Before you begin the installation, it’s critical to understand the system’s layout and know where the SRH needs to be installed. Ensure the device’s location is cleared and prepared for installation.

Step 2: Positioning the Slip Ring Harness

Carefully place the SRH at its designated position within the system. Depending on the specific layout, this could involve securing the stator (stationary part) while ensuring the rotor (rotating part) is connected with the designated rotating segment.

Step 3: Secure the Device

Use the screwdriver and screws to secure the SRH in place within the system. This step might involve securing the SRH’s housing to a stable part of the system to prevent it from moving around during operation.

Step 4: Connect the Wires

You may then need to connect the wires of the SRH to the related system parts. This will involve attaching power or signal cables from the stator to the source or output device and ensuring the rotor’s connections are established with the rotating element of the system.

Step 5: Final Checks

Once the SRH is connected, conduct a final check to make sure everything is properly assembled. Ideally, use a multimeter to confirm the SRH’s electrical connections and ensure there’s no short-circuiting. Check the rotor’s movement to make sure it’s not obstructed and can rotate freely.

Step 6: Power Up

Finally, once you’re confident everything has been correctly installed, it’s time to power up the system and observe how the SRH functions. If there are any issues detected, switch off the system and inspect the installation for any disconnects or issues.

Installing a Slip Ring Harness requires careful attention to detail and a methodical approach. Always follow safety procedures to ensure a smooth and safe installation process.

Of course, let’s look into the advantages and applications of a Slip Ring Harness.

Benefits of Using Slip Ring Harness

The Slip Ring Harness (SRH) provides a creative solution to a problem that could severely inhibit the operation of many mechanically rotating systems. Its unique properties enable the transmission of power or data across rotating interfaces, a function that gives it considerable advantages over traditional methods and opens up a plethora of potential applications.

Comparative Advantages

An SRH offers numerous benefits compared to conventional methods of addressing rotation in systems:

- Uninterrupted Transmission: As the slip ring harness is engineered to operate smoothly during rotations, it ensures continuous transmission of power or signals, unlike traditional systems where the transmission can be disrupted during rotation.

- Reduced Maintenance: SRH systems, due to their design, endure less wear and tear, thereby reducing the necessity for frequent replacement or maintenance compared to systems using wired connections.

- Flexibility: SRH can accommodate a wide range of power and signal types (including digital, analog, and even optical signals) making it versatile for various applications.

- Compactness: Slip rings save space as they are generally more compact compared to other solutions like cable reels.

Real-World Applications and Case Studies

The SRH has many real-world applications due to its advantages:

Wind Turbines

Wind turbines exemplify the SRH’s role in renewable energy systems. Being subject to constant rotation, the SRH is crucial in transmitting power from the turbine to the grid without interruption.

Medical Imaging

In medical imaging technology, such as CT scanners, the SRH enables the scanner’s rotating parts to transmit signals continuously to the stationary systems, improving accuracy and image clarity.

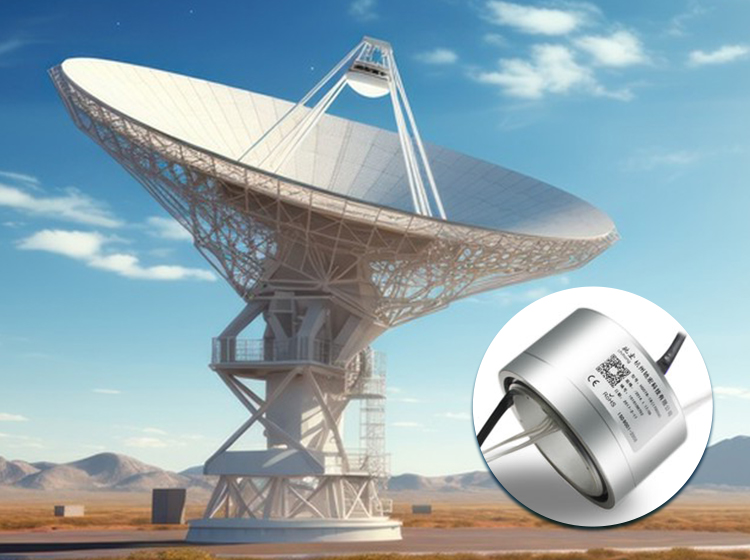

Satellite Antenna Systems

In satellite antenna systems, the SRH ensures continuous tracking of the satellite by transmitting data and power across the rotating antenna frame, improving communication and performance.

In conclusion, the Slip Ring Harness’s unique ability to sustain electrical conductivity across rotating interfaces brings substantial benefits and broad applications, making it an invaluable component in many modern systems. Understanding the extent of its benefits can motivate improved utilization of current applications and inspire new innovative applications in other fields.

Slip Ring Harness Maintenance

Though a Slip Ring Harness (SRH) comes with the advantage of reduced maintenance requirements compared to traditional rotational solutions, it is still essential to upkeep and monitor its condition for optimal performance and longevity. Everyone involved in its operation should be well-versed in its maintenance aspects.

Routine Check

Scheduling regular checks and inspections for your SRH can be the first step in ensuring its proper functioning. Here are some key aspects to examine during routine maintenance:

- Visual Inspection: Make sure the SRH housing is undamaged, with no visible signs of wear or cracks. Likewise, check the attached wires and connections for damage or fraying.

- Brushes and Rings: Inspect the brushes for wear, and look at the condition of the rotor rings. Ensure contact between the brushes and rings is maintained and that there’s no excessive buildup of debris in the area.

- Bearings: Verify that the bearings are rotating freely without any obstruction, and listen for any unusual noises that might indicate issues with the bearings.

- Electrical Connection: Use a multimeter to test the integrity of the connections between the source/receiver and the SRH. This will help identify any undesirable changes in resistance or potential short-circuiting.

Troubleshooting Common Issues

In case issues do persist or arise during operation, troubleshooting becomes essential. Here are some common issues and their potential solutions:

- Intermittent Transmission: If power or signal transmission is disrupted or intermittent, first check the brushes for wear. Worn brushes, if present, should be replaced. Additionally, clean any debris from the contacts between the brushes and rotor rings to ensure optimal contact.

- Difficulty in Rotation: If the rotor is not rotating smoothly, inspect the bearings for damage, blockages, or inadequate lubrication. Damaged bearings should be replaced, and any obstructions removed. If lubrication appears insufficient, reapply the proper lubricant.

- Overheating: If the SRH is experiencing overheating, check the electrical connections, ensuring there are no short circuits or abnormally high resistance. Resolve any issues found by replacing damaged components or adjusting connections.

- Unusual Noises: If you hear unusual sounds coming from the SRH during operation, examine the bearings or the brushes and rotor rings for damage or misalignment. Replace or repair as necessary based on your findings.

Maintaining the Slip Ring Harness entails regular checks, inspections, and resolving any issues that arise during its operation. By doing so, you ensure the SRH’s long-term efficiency, enhanced performance, and reliability across its diverse range of applications.

Conclusion

In conclusion, the Slip Ring Harness (SRH) is an innovative solution that addresses the complex challenge of transmitting power and data across rotating interfaces. Its numerous benefits, such as uninterrupted transmission, reduced maintenance, flexibility, and compactness, make it a vital component in a wide range of applications, including wind turbines, medical imaging, and satellite communication systems.

As the demand for efficient and uninterrupted data and power transmission continues to grow, the SRH will likely play an increasingly important role in various industries. Proper installation and regular maintenance of an SRH are crucial for its optimal operation, reflecting the importance of understanding the SRH’s design and applications in modern mechanical systems.

FAQ about Slip Ring Harness

Here are brief answers to a few common questions related to Slip Ring Harness:

Q: What is the average lifespan of an SRH?

A: The lifespan of an SRH depends on its usage and environment, but generally varies from 50 to 200 million revolutions for mechanical slip rings and up to a billion for contactless ones.

Q: When do I replace the brushes?

A: Replace brushes when they’ve reached their wear limit or exhibit issues with signal transmission.

Q: Are there any alternative solutions to Slip Ring Harnesses?

A: Some systems may use contactless solutions, such as RF or capacitive couplings, but they’re generally more expensive and less reliable compared to SRHs.

Q: Can I install an SRH outdoors?

A: SRHs can be installed in both indoor and outdoor settings. Ensure selecting one with adequate protection against environmental factors such as dust, moisture, and temperature fluctuations.

See What We Can Do