Understanding the operation of a device as intricate as a Direct Current (DC) generator can appear complex. However, breaking down its components and functionalities can simplify this understanding beautifully. Among these components, one of the most crucial elements is the slip ring—a device as fascinating as it is essential.

Slip rings, better comprehended as electromechanical devices, work as essential connectors between the stationary and rotating parts of DC generators. They step up to the plate by ensuring a flawless electrical connection that enables the transfer of power or signals from an armature that’s constantly in motion to a stationary load. Thus, they act like unsung heroes, subtly bridging the gap between movement and steadiness, rotating motion, and stationary applications.

Complementing the slip rings’ fervor is the DC generator — the mammoth of a machine that converts mechanical energy into direct current electrical energy. Engineered to provide a reliable source of steady electrical power, DC generators generate electricity through the mechanical motion of coils in a magnetic field—an operation that’s nifty and significant for numerous applications from power tools to vehicles.

The slip ring in DC generator has an important function, forming a seamless partnership that leverages intricate design with significant power production to sustain a consistent flow of energy. As we progress further into understanding this tandem’s intricacies, a focus on the dynamics that characterize their unique and combined roles is crucial. This focus will not only help inform us about the slip ring and DC generator individually but also illuminate the interplay between them in the fascinating sphere of power generation.

Function and Importance of Slip Rings in DC Generators

As we delve into the intricacies of the DC generator system, it’s fascinating to witness how individual components function in synchronicity to achieve the smooth production and transmission of electrical energy. One such intriguing component is the slip ring, an unassuming device that plays a pivotal role in the operational dynamics of a DC generator.

Slip rings, often referred to as rotary electrical joints, have primarily one job: ensuring flawless conduction of electricity from a rotating element to a stationary one. Here’s how it works within a DC generator system: the generator’s rotor (in case of a wound rotor generator) or armature with a winding on it rotates within a magnetic field. This rotation induces an electrical current within the conductor. However, for this generated electrical energy to be utilized, it needs to be transferred to the stationary part of the generator which is connected to the external circuit. Enter the slip ring.

The slip ring, usually made of a highly conductive metal like copper, is attached to the rotor armature’s winding. As the armature rotates, the slip ring turns in sync with it. Solid carbon brushes, in contact with the slip ring, collect the generated current. These brushes remain stationary and, acting as an interface, transfer the gathered electric current to the stationary part of the generator that leads to the external circuit.

The importance of slip rings within DC generators is multifaceted. Their role isn’t just limited to being a channel facilitating the flow of current from the rotating armature to the stationary parts of a generator. They play an integral part in enabling the unidirectional flow of direct current through the systematic reversal of the armature coil’s connections after every half rotation. This function is crucial because it’s what allows the generator to produce direct current—power that’s ubiquitous in our everyday lives from mobile devices to computer systems.

This ingenious functionality underscores the importance of slip rings in a generator setup. Without them, the energy produced inside the rotating armature would have no way to reach the outside world. They may not be the most prominent part of a generator in terms of size, but their role in connecting the rotating and stationary aspects of a generator magnifies their importance significantly, rendering them indispensable.

Construction and Design of Slip Rings in DC Generators

Certain facets of the components within a DC generator are as compelling as their function; the physical aspects embody the thoughtful design and engineering behind them. Slip rings are a prime example of this. Their construction and design details mirror careful attention to the generator’s functionality through the roles they play.

Primarily, slip rings are constructed from highly conductive materials, typically metals such as copper or brass. These materials are chosen for their excellent electrical conductivity properties, enabling efficient transmission of current from the rotating armature to the stationary brushes with minimal energy loss.

As for the shape and size of slip rings, they are almost always cylindrical. The cylindrical shape ensures a consistent area of contact between the rotating ring and stationary brushes, enabling the seamless transfer of electrical current even during rotation. The size of the slip ring is not constant; it varies based on a multitude of factors, including the size of the generator, the amount of current it’s designed to handle, and the specific application it is intended for. Essentially, the dimension of a slip ring is directly proportional to the load it is anticipated to bear; a heavier load necessitates a larger slip ring.

These physical attributes are not random by any means. They are intentional designs that contribute significantly to the slip ring’s overall functionality within a DC generator system. The choice of highly conductive materials reduces resistance to electricity flow, thereby increasing the efficiency of power transfer and reducing undesired heat generation. Similarly, the cylinder’s shape and size go hand in hand — the consistent contact area reduces the possibility of signal disruptions, while the ring’s appropriate sizing ensures it can handle the electrical load for which it’s designed.

The construction and design of slip rings in DC generators underscore the intricate balance between physicality and functionality in machine components. They stand as a testament to how astute engineering can create efficient, precise elements tailored to their application, every aspect designed to contribute to the seamless functionality of the generator as a whole.

Working Principle of Slip Rings in DC Generators

Unraveling the working principle of slip rings in DC generators enables us to appreciate the simplicity and effectiveness of this crucial component. At their core, slip rings function based on the basic principles of electromagnetism and electric conduction.

The operating principle of slip rings revolves around establishing a continuous, robust electrical connection between a rotating and a stationary component. This is essentially needed to ensure seamless transmission of electrical power or signals from the armature winding to the load circuit in the DC generator system.

In a typical DC generator, the armature winding mounted on the rotating shaft generates electricity due to mechanical rotation in the magnetic field. However, the output of the load circuits is stationary. To establish a connection between the rotating armature and stationary load, slip rings are affixed to the armature winding.

Two solid carbon brushes, connected to the external circuit, maintain contact with these rotating slip rings. As the armature rotates, it induces an electromotive force (EMF) in the winding. This generated EMF, or electricity, then is transferred to the slip rings via the brushes. The current in the circuit from the brushes is always direct, no matter the changing magnetic poles. This is due to the commutator action of the brushes against the slip rings that connect and disconnect the armature coil from the circuit to maintain unidirectional current flow.

Unfortunately, without diagrams or visuals here, the clarity is slightly restricted. Typically, a diagram illustrating a DC generator with clearly marked stationary carbon brushes, rotating slip rings, and armature winding will get this concept across most effectively.

To sum it up, the working principle of slip rings lies in their ability to maintain a persistent electrical pathway between stationary and moving components. This principle enables the slip rings to transfer the generated electricity flawlessly from the armature to the external load circuit, thus powering our everyday devices reliably and efficiently.

Slip Rings in DC Generators: User Concerns and Solutions

Like any mechanical component, slip rings in DC generators come with their own set of challenges. Users often have concerns about the durability, performance, and maintenance of these parts that could potentially impact the generator’s overall functioning.

- Durability Concerns: Regular wear and tear on slip rings is quite common, primarily due to their constant motion and interaction with the brushes. Excessive wear can result in rough surfaces that may lead to inefficient operation or circuit disruptions.

Solution: Opt for slip rings made of high-quality, durable materials like hard silver alloys or specific grades of copper to enhance the component’s lifespan and reliability. Regular inspection and timely replacement of slip rings with evident wear can uphold generator performance and longevity. - Performance Issues: Inefficient electrical conductivity can compromise the performance of DC generators. This could occur from deterioration in the physical condition of the slip rings or the presence of dust and grime.

Solution: Regular cleaning of slip rings can prevent dust accumulation and facilitate efficient electricity transmission. Also, ensuring the slip rings and brushes are properly aligned guarantees optimal contact, which, in turn, can enhance their performance. - Maintenance Requirements: Over time, slip rings can degrade or corrode, affecting their efficiency and creating a need for continuous monitoring and maintenance.

Solution: Regular maintenance checks are not just preventive measures; they are crucial to maintaining the seamless operation of DC generators. An adequate maintenance routine should include cleaning, inspection for wear and corrosion, and timely replacement of brushes and slip rings, if necessary. - Installation Concerns: Proper setup of slip rings and brushes is a concern too since improper installation can affect generator performance.

Solution: Efficient installation of slip rings can be achieved by strictly following manufacturer guidelines or employing a professional, ensuring secure alignment and connection for optimal performance.

While these concerns are valid, acknowledging and addressing them can substantially enhance the operational efficiency and longevity of DC generators. By paying close attention to component quality, preventive maintenance, and regular check-ups, users can bolster the performance and durability of their generators and, by extension, the slip rings within them.

Slip Rings in DC Generators: Recent Technological and Future

As in any field crossing the intersection of science and technology, slip ring technology used in DC Generators does not stand still. Advancements and improvements are frequent, driven by the need for better performance, durability, and efficiency in power generation.

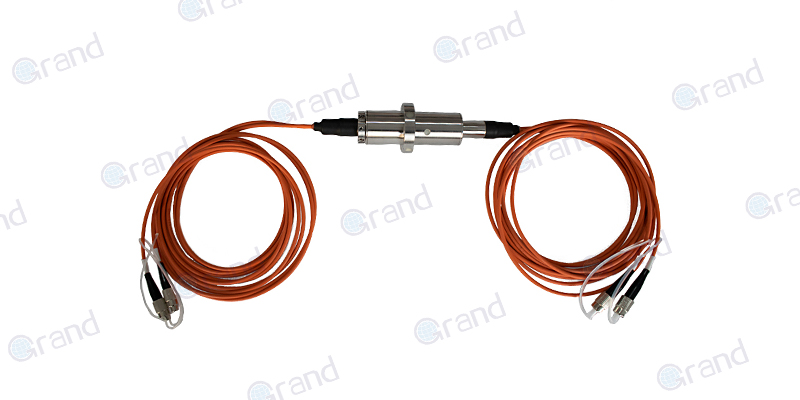

One significant recent development has been the introduction of fiber optic slip rings, also known as FORJs (Fiber Optic Rotary Joints). This technology makes use of optical fibers to transmit electrical signals, enabling larger amounts of data to be transmitted over greater distances and with much less signal loss compared to traditional metallic slip rings.

Additionally, the incorporation of contactless slip ring technology or wireless rotary joints is on the rise. These designs eliminate physical contact between brushes and slip rings, reducing wear and tear and offering a higher service lifespan.

Furthermore, the use of advanced materials is becoming increasingly commonplace. Researchers are continually exploring and testing new materials that offer an even greater degree of electrical conductivity, corrosion resistance, and wear resistance than their traditional counterparts. These material developments could substantially enhance the working life and overall performance of slip rings.

Looking to the future, the advancement in slip ring technology seems promising. Researchers continue to push the envelope in every direction – tougher and more conductive materials, smarter design strategies, and more efficient signal transmission methods.

The rise of AI and machine learning heralds the potential for smart maintenance systems, predicting and alerting for required maintenance before significant wear and tear occurs. Increased diversification in slip ring designs tailored toward specific use-case scenarios and environments could also lead to higher efficiency and prolong the component’s lifespan.

In conclusion, while slip ring technology for DC generators has come a long way, the journey is far from over. The constant drive to overcome present limitations and enhance performance is likely to yield exciting innovations and improvements in the years to come.

Conclusion

Understanding the intricacies of slip rings in DC generators serves multiple purposes—it enriches one’s knowledge, empowers troubleshooting, and improves operational efficiency. With such significant benefits on offer, it becomes evident how indelible a role the humble slip ring plays in the often-complex world of DC generators.

FAQs about Slip Rings in DC Generators

As users navigate through the world of DC generators and their components, several questions may arise about slip rings – their installation procedure, troubleshooting measures, lifespan expectations, and more. Here, we try to address some of these frequently asked questions concisely yet informatively.

Q: What is the typical procedure for installing slip rings in a DC generator?

A: The installation process for slip rings usually involves attaching them to the rotating shaft of the armature winding. It must be carried out as per the manufacturer’s guidelines or by a professional to ensure the right alignment with the stationary brushes, ensuring optimal contact and smooth operation.

Q: If a generator is malfunctioning, how can I troubleshoot issues related to slip rings?

A: A few common signs of slip ring issues include inefficient generator performance, excessive heat, or sparks at the slip ring-brush interface. If these occur, inspect the slip rings for excessive wear, corrosion, or improper alignment with the brushes. You might also want to check for cleanliness, removing any accumulated dust or grime. If issues persist, it’s advisable to seek professional help.

Q: What is the expected lifespan of slip rings in DC generators?

A: The lifespan of slip rings can hugely vary and depends largely on factors such as the quality of the materials used, operational load conditions, maintenance routines, and environmental factors. Nonetheless, with regular maintenance and under normal working conditions, high-quality slip rings should comfortably last several years.

Q: How often should slip rings be formally inspected?

A: Ideally, a formal inspection of slip rings, along with other generator components, should be performed annually. However, for generators under heavy use or harsh conditions, more frequent inspections might be necessary.

See What We Can Do