As you navigate through the various domains of electrical engineering, one concept, “Slip Ring Power Transfer,” stands out for its influential role in multiple applications. The slip ring, a relatively lesser-known component, underpins a significant portion of modern industry machinery. This article begins by providing an insightful overview of this critical technology, shedding light on the science behind slip rings.

As we initiate this exploration into the realm of slip rings, we aim to do more than simply present basic information. The purpose of this exposition, instead, is layered. First, to establish the foundational understanding around slip rings. Next, to discuss the subtleties of slip ring power transfer— a unique process that warrants careful study and finally, to extrapolate this understanding to its numerous applications, thereby showcasing the undeniable influence slip rings wield in the field of power transfer.

From wind turbines to medical machinery, slip rings ensure seamless power transmission. Their unparalleled contribution across multiple fields is a testament to their technical sophistication and utility. It is this dynamic interaction between slip rings and their myriad applications that we aim to portray through this article.

So, plunge into this detailed expose to appreciate the nuances of slip ring power transfer. By illuminating this crucial technology, we hope to enrich your understanding beyond a mere definition, emphasizing the role of slip rings in a broader, practical context, thereby bestowing a sense of coherence to the article’s purpose.

Understanding the Concept: The Principle of Slip Ring Power Transfer

Navigating deeper into the plains of power transfer, our focus turns toward the slip rings. At first glance, these humble rings might seem no more than a peripheral component. However, once we delve into the details of their workings, we shall uncover an exemplary technological marvel that is indispensable.

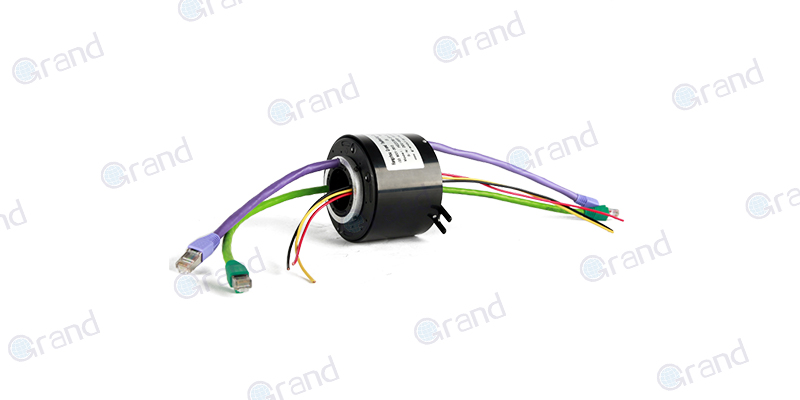

In essence, slip rings operate on the principle of electrical continuity and rotary transformation. Defined as an electrical device that allows the transmission of power and electrical signals from a stationary to a rotating body, a slip ring comprises brushes and rings— one stationary and the other rotating— that remain in continuous contact during the rotation, enabling efficient transmission.

Digging into the intricacies, we will further elucidate the physical and operational factors influencing a slip ring’s performance. From the ring’s conductivity, brush pressure, and speed of rotation, to contact reliability, we will break down each factor’s contribution leading to an effective power transfer.

Transcending through the specifics of slip ring functionality, the article will then focus on the pièce de résistance— the role of slip rings in power transfer. It’s here that we encounter the real marvel of slip rings: their versatile capacity to facilitate power transition across diverse platforms.

In the grand machinery of power transfer, the slip ring functions as the critical interface or link between the static and rotating parts. It plays a quintessential role in applications that require uninterrupted power or signal transmission during spinning or rotation— a feat that conventionally poses considerable technical challenges.

Accumulating the strands of comprehension about the basic principles of slip rings and intertwining them with the broader context of power transfer, we’ll paint a cohesive picture that further underlines slip rings’ paramount importance in various technological realms.

The Design and Manufacturing of Slip Rings

Having grasped the fundamentals of slip ring principles and their function in power transfer, the reader’s journey now ventures into the world of their design and manufacturing. It is here that one can truly marvel at the nuanced complexities that underlie these pivotal devices.

Our exploration commences at the design phase of slip rings. Herein, a plethora of considerations commands attention. From determining the suitable dimensions, number of channels, and rotational speed, to selecting the type of signals to be transported – designers must orchestrate a symphony of technical parameters to create an effective design blueprint.

From design, we transition to the actualization stage, picturing the manufacturing process of these intricate power transfer conductors. The journey isn’t simple, as transforming a theoretical design into a functional slip ring demands precision and control. However, it is this meticulous crafting process that enhances the reader’s appreciation for the prowess a fabricated slip ring embodies.

One of the crucial and often compelling stages is the choice of materials. The types of metals used for conductive rings, the kind of brushes, and their interactive materials, all significantly influence the slip ring’s performance. Our discussion thus delves into the careful decision-making process behind the selection of these elements.

Next comes the utilization of engineering techniques and production technologies. The meticulous assembly process and the manufacturing technology used— from welding, and soldering techniques, to advanced CNC machines and testing equipment, reveal how subtle manipulations culminate in the making of the slip ring.

This peek into the creation of slip rings doesn’t merely recount a journey from the design phase to production, but also paints a vivid picture of the value embedded in each ring. It emphasizes the coherence between the design values, material considerations, manufacturing techniques, and the final product’s role in power transfer, creating a bridge of comprehension for the reader to cross over, from understanding slip rings in theory to appreciating them in practice.

The Use of Slip Rings in Power Transfer

Continuing our odyssey into the realm of slip rings, we now immerse ourselves in their world as it materializes, observing slip rings in action. This section focuses on uncovering the unique attributes of slip rings that sanction their applicability across an extensive range of industries, demonstrating their preeminence in managing power transfer.

First, we explore how the innate uniqueness of slip rings transcends conventional power-transfer limitations. Due to their ability to maintain continuous electrical connection during rotation, they enable a level of versatility not easily achieved through alternative components. By overcoming the challenges of wear and noise, slip rings deliver seamless power and signal transmission in complex applications— from robotics to radar antennae and beyond.

Now equipped with the understanding of slip ring capabilities, we turn our attention to the practical demonstration of these devices enabling power transfer in diverse industrial sectors. A spectrum of implementations unfurls, including renewable energy, where slip rings hold a pivotal role in wind turbines, capturing and transferring wind-generated power. Moreover, we observe their usage in sectors such as healthcare with CT scanners, media technology with CCTV cameras, and even in military equipment.

Each of these practical examples not only highlights the versatility of slip rings but also weaves a contextual narrative that reinforces their indispensability in various applications. Ultimately, these insights forge a coherent connection between the theoretical principles and the practical implications of slip rings in the world of power transfer.

As we progress through this segment, the sheer breadth of adaptations that employ slip rings becomes increasingly evident, painting an undeniable truth: slip rings truly are the unsung heroes in the field of power transfer that maintain the lifeblood of countless industries. It is through this comprehensive exploration that readers can fully appreciate the magnitude of slip rings’ contributions in the real world.

The Future of Slip Rings in Power Transfer

As we stand on the precipice of current technological accomplishments, our gaze naturally travels across the horizon, seeking glimpses of the future. This concluding section of our exploration mirrors such a quest— revealing the forthcoming progression of slip rings in the domain of power transfer.

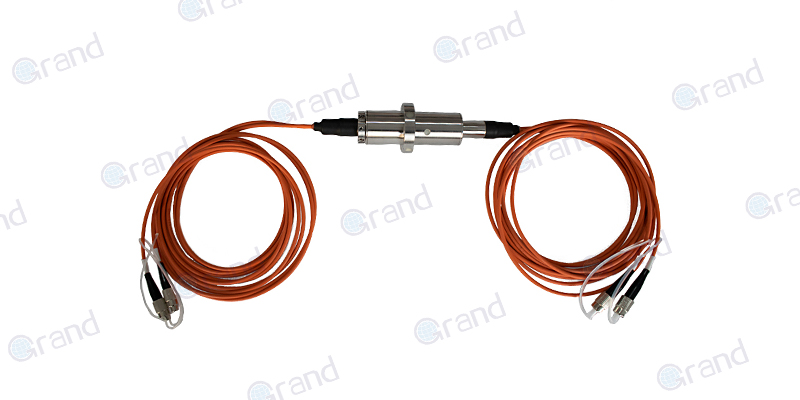

Begin with an overview of the recent and upcoming technological advancements that are transforming the landscape of slip ring production. From the incorporation of nanotechnology for enhancing conductivity to the development of wireless or “contactless” slip rings, it is evident that the realm of slip ring performance is continuously expanding. This productive churn of tech-influenced metamorphosis underscores the commitment to enhance slip rings’ efficacy and expand their applications.

Following the appreciation of current advancements, the discussion shifts towards potential future developments in slip ring technology. From envisaging the design of slip rings that can operate at higher speeds and currents, to the prediction of slip rings capable of functioning in challenging environments, we explore various evolutionary possibilities.

We take further steps to evaluate the implications of these theoretical advances, contemplating how they could revolutionize the power transfer sector. For instance, more efficient slip rings could increase the efficacy of renewable energy systems, or their ability to withstand wear could extend the operational life of industrial equipment, ultimately leading to reduced maintenance costs.

Casting our vision towards the future, we maintain coherence with the overarching context of this discussion — understanding slip rings’ principle, design, application, and prospects. This holistic narration ensures that the readers while being ushered into tomorrow’s technologically advanced versions, remain rooted in the comprehensive knowledge imparted about the slip ring’s journey.

Consequently, this prospective glance offers not just a view but a vision of tomorrow that marries the traditions of slip rings with a future echoing nuances of technological marvels, promising a future full of innovations, and even more enhanced power transfer capabilities.

Conclusion

To conclude, the article encapsulates the role of slip ring power transferrals in electrifying today’s rapidly pacing world. Not only an enlightening read, but this guide also serves as a reference point for future engagement with this significant, yet often overlooked, technology.

FAQs around Slip Ring and Power Transfer

Q: How Does a Slip Ring Work?

A: A typical slip ring design involves conductive rings attached to the rotating part of the device and brushes that transfer signals or power to or from the stationary component. As the part with the conductive rings rotates, the brushes maintain contact, ensuring uninterrupted transmission of power or signals. In the case of capacitive or inductive slip rings, the principle remains the same, but the power or signal transfer is executed contactless through electromagnetic fields.

Q: What is Power Transfer?

A: Power transfer refers to the process of transmitting electrical power from one component or system to another. In the context of slip rings, it usually refers to the transmission of power from a stationary system (like a power source) to a rotating component (like a motor in machinery).

Q: Why are Slip Rings Important in Power Transfer?

A: Slip rings are vital in power transfer because they facilitate the continuous flow of power between stationary and moving parts without interrupting the rotation. This ability makes slip rings indispensable in applications like wind turbines, rotating antennae, or any machinery where transferring electricity or signals to rotating parts is necessary.

Q: What Types of Signals Can a Slip Ring Transmit?

A: While slip rings are commonly used to transmit power, they are also intended for signal transmission, including analog signals, digital signals, data signals, as well as video and audio signals. The nature of signals a slip ring can transmit depends on its design and application.

Q: How are Slip Rings Maintained?

A: Maintenance of slip rings mainly entails periodic inspections, cleaning, lubrication of mechanical components (where applicable), and parts replacement. For specific maintenance procedures, it is always recommended to refer to the manufacturer’s guidelines.

Q: What are the Latest Trends in Slip Ring Technology?

A: Some of the latest trends in slip ring technology range from miniaturization and improved material-aided performance to integration with advanced systems for real-time monitoring and predictive maintenance. There’s also a growing emphasis on creating more energy-efficient slip ring designs that reduce power loss.

See What We Can Do