In the intricate mechanics of our technologically advanced world, some elements, like Slip Ring Sensors, often go unnoticed despite playing crucial roles across a multitude of industries. These essential components facilitate the critical transmission of power and data between stationary and rotating parts in various systems. In this comprehensive guide, we aim to demystify the complex world of Slip Ring Sensors, starting with their basic definition, shedding light on their integral features and structure, and walking through their functionality in a manner understandable to the curious reader and professional alike.

Our exploration doesn’t stop merely at understanding these sensors; we’ll broaden the horizon by examining the wide range of industries these devices serve. We’ll provide real-world examples and differentiate the types of Slip Ring Sensors based on their functions and applications. Additionally, we’ll delve into their key unique features, maintenance, and durability considerations, common user concerns with their troubleshooting, and insights into the selection of quality sensors. So, whether you’re a professional seeking technical insights or merely intrigued by the behind-the-scenes of everyday technology, this guide on Slip Ring Sensors is for you.

Definition of Slip Ring Sensors

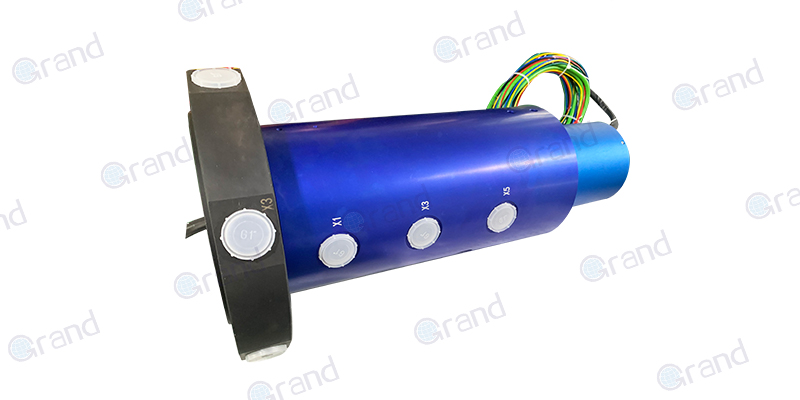

Slip Ring Sensors, often acknowledged as a key component in the field of electromechanical engineering, serve as a remarkable solution in systems and devices where the transfer of electrical signals, power, or even fluids is required between stationary and rotating components. These sensors not only provide seamless communication but also enable the critical capabilities and functions of various systems while maintaining a compact, robust design that minimizes wear and tear.

Nested within the larger family of rotary joints, Slip Ring Sensors consist of two main parts: a rotor (the rotating part) and a stator (the stationary part). Both of these components are comprised of conductive materials, and their design can range from relatively straightforward to highly complex, based on the requirements of the application. The structure of Slip Ring Sensors typically encompasses a center that allows them to rotate and transfer power while maintaining steadfast contact with stationary brushes that comprise essentially conductive elements such as precious metals, carbon, or copper. Furthermore, the sensor assembly can integrate additional features, such as enclosures, bearing systems, and electrical connectors, to protect the internal mechanisms, ensure smooth rotation, and facilitate easy interfacing with the machinery at large.

Boasting a range of innovative features for optimized performance, Slip Ring Sensors find their utility in numerous critical applications, including robotics, defense, medical equipment, wind turbines, and beyond. As such, understanding their mechanism and optimal use not only sheds light on their vital role within the myriad of industries but also contributes to our overall comprehension of the technological foundation upon which our modern lives depend.

Understanding Slip Ring Sensors

The seemingly complex world of Slip Ring Sensors becomes significantly easier to understand once you grasp their basic principle of operation: enabling a reliable connection between a stationary structure and a rotating part. It’s all about the continuous transfer of data or power, irrespective of the rotational movement. The effortless integration of these sensors into various types of machinery underscores their significance in today’s highly interconnected, rotating technological ecosystems.

Let’s break down the working of a Slip Ring Sensor into simpler terms. The entire process revolves around two primary components: the stator (a stationary part) and the rotor (a rotating part). The rotor, typically a ring made of a conductive material, rotates around a center, which is often magnetic and keeps the rotor in place during its revolution. The stator, on the other hand, includes brushes that consistently touch the rotor as it spins.

As the rotor revolves, these brushes maintain uninterrupted physical contact and conduct the electric signals or power between the stationary and rotating part. This transmission is made possible by the minute presence of an insulating gap that allows the electric current to flow without any hindrance.

To understand the operational nuances better, visual aids — such as diagrams or cutaway views — can come in handy. Imagine an image showcasing a simple Slip Ring Sensor: a conductive ring, rotating around its magnetic center while a pair of brushes touch the ring’s surface throughout its rotation. The arrows indicating the power or data flow between the stationary and rotating parts present a clear understanding of the sensor’s operation.

Comprehending the functioning of Slip Ring Sensors allows us to appreciate the intricate dynamics running our technologically advanced world. These essential components, despite their unassuming appearance, undertake monumental tasks within their diminutive frameworks, making them fascinating subjects in the ever-evolving domain of electromechanical engineering.

Applications of Slip Ring Sensors

The extensive application of Slip Ring Sensors across various industries testifies to their importance in facilitating smooth operations. Let’s explore how these sensors contribute to different sectors precisely.

Wind Energy

In the wind energy sector, Slip Ring Sensors form a critical component of Wind turbines. The major challenge lies in transmitting power and data from the nacelle, a part that rotates to face the wind direction, to the non-rotating tower. This is where the Slip Ring Sensors come into play. They enable a seamless transmission between these parts, ensuring the turbines operate effectively and feed generated electricity into the grid without interruption.

Medical Gear

Slip Ring Sensors have a significant role within the medical industry too. One of the primary examples lies in their usage in Computer Tomography (CT) scanners. CT scanners consist of a rotating gantry that houses the X-ray tube and detectors. The Slip Ring Sensors in such devices allow for continuous rotation of the gantry, thereby enabling the continuous acquisition of image slices that form a complete, detailed image of the patient’s body part being examined.

Robotics

The field of robotics has given rise to precision applications where complex movements need to be controlled effectively. Whether in robot arms or advanced mobility systems, Slip Ring Sensors are indispensable for allowing the transmission of control signals and power to rotating parts. Through this, these sensors ensure smooth, accurate movements in robotic systems, increasing their efficiency and applicability across many domains.

Defense

In defense systems, command and control, especially in communication and radar systems, depend highly on uninterrupted and reliable data flow. In radars, for instance, the antenna must continuously rotate to provide a 360-degree view of the surroundings, but it must also receive power and transmit data back to the static system. This is made possible by integrating Slip Ring Sensors, ensuring seamless, uninterrupted, transmission of signals despite the rotation.

The varied applications of Slip Ring Sensors across these industries underscore their pivotal role in maintaining operational coherence in a myriad of systems. From enhancing renewable energy solutions to aiding medical diagnostics, improving robotics’ precision to elevating defense capabilities, Slip Ring Sensors continue to shape the world around us.

Types of Slip Ring Sensors

As diverse as their applications are, Slip Ring Sensors too come in various types, each catering to specific requirements and operational environments. The key categories include Electrical Slip Rings, Fiber Optic Rotary Joints, and Fluid Rotary Unions.

Electrical Slip Rings

Electrical Slip Rings are the most commonly recognized type of Slip Ring Sensors. They primarily facilitate the transmission of electrical signals or power between stationary and rotating components. The applications of these sensors are vast, covering sectors like automation, wind turbines, manufacturing machinery, and countless others where rotation and data or power transfer coexist.

Fiber Optic Rotary Joints (FORJs)

Fiber Optic Rotary Joints (FORJs) represent a more advanced type of Slip Ring Sensors. Unlike traditional electrical slip rings that transmit electrical power or signals, FORJs specialize in the transmission of optical signals and data. Combining rotation with high-speed, large-capacity data transfer, these sensors are mainly prevalent in telecommunications, maritime communication, advanced radar systems, and certain remote sensing applications.

Fluid Rotary Unions (FRUs)

Fluid Rotary Unions (FRUs) deviate from the standard concept of Slip Ring Sensors but belong to the same broad family serving similar, yet unique functions. FRUs allow for the transition of fluid or gas from stationary to rotating parts. As a result, these sensors find usage in industries where rotational machinery requires constant fluid supply for tasks such as cooling, heating, or transferring material, such as in industrial processing units, petrochemical plants, and even some specialized machinery in the food and beverage industry.

By understanding each Slip Ring Sensor type and its unique properties, we can better comprehend their extensive usage across various industries and appreciate their crucial role in global technological progress. From transmitting simple electrical signals to facilitating liquid flow, the realm of Slip Ring Sensors is indeed diverse and indispensable to our mechanized world.

Key Features of Slip Ring Sensors

Slip Ring Sensors, in their various forms, possess distinctive features that make them indispensable in multiple industrial applications.

Seamless Transmission

The ability to provide uninterrupted transmission of power or data signals between stationary and rotating structures is perhaps the most critical feature of Slip Ring Sensors. In industries like wind energy and defense, this attribute is fundamental to maintain continuous operation of wind turbines and radar systems respectively.

Versatility

Slip Ring Sensors offer versatility in terms of the type of signals they can handle. Be it electrical current in traditional applications, optical signals in high-speed data transmission systems, or even fluid transfer in specialized scenarios, these sensors can cater to a multitude of requirements.

Durability

These sensors demonstrate excellent durability, sustaining operations in various environments over extended periods. Their ability to withstand different conditions — from the harsh weather confronting wind turbines to the intense operations within medical devices — makes them a preferred choice across diverse sectors.

Compactness

Despite their robust performance, most Slip Ring Sensors maintain a compact and lightweight design, integrating seamlessly into different types of machinery without significantly impacting the overall size or weight. This feature gains prominence in areas like robotics and medical instrumentation, where space constraints are often a significant challenge.

Low Friction Operation

In their design, these sensors ensure low friction during operation, translating to minimal wear and tear and longer operational life. This characteristic is specially valued in sectors like defense and telecommunications where equipment reliability and lifespan are of paramount concern.

The key features of Slip Ring Sensors underline their significance in the vast industrial landscape. Whether it’s ensuring the continuous functioning of a wind turbine, facilitating precise medical diagnostics, or enabling smooth operations in a robotic arm, these robust and reliable components meet a diverse range of needs, rendering them indispensable in our technologically driven world.

Maintenance and Durability of Slip Ring Sensors

The durability of Slip Ring Sensors is one of their defining features, and with proper maintenance, these crucial components can offer years of dependable service.

Lifespan of Slip Ring Sensors

The lifespan of Slip Ring Sensors can vary widely based on their type, usage, and operating environment. Electrical slip rings used in moderate conditions can last for tens of millions of revolutions. On the other hand, fiber optic rotary joints and fluid rotary unions, due to their specialized nature and precision construction, might have a different life expectancy, mainly dictated by the system they are integrated into and their operating conditions.

Maintaining Slip Ring Sensors

Despite their durability, ensuring the longevity of Slip Ring Sensors requires proper maintenance.

Regular Inspection

Regular inspections of the Slip Ring Sensors should be a part of routine maintenance schedules. This includes checking for wear and tear, any electrical anomalies, or the need for cleaning.

Cleaning

Over time, slip ring surfaces may accumulate debris, which can affect their performance. Regular cleaning using suitable solvents is hence essential. However, recommendations from the manufacturer should be strictly followed to avoid any damage.

Replacement of Worn Parts

Brushes in electrical slip rings, being the primary point of contact, can wear out over time. Regular inspection and timely replacement of these brushes can extend the lifespan of the entire assembly.

Proper Installation

Correct installation is a crucial factor in ensuring the longevity of Slip Ring Sensors. Misalignments or improper fitting can cause excessive wear, reducing the operational life.

Lubrication

In some instances, a thin coat of lubricant, applied as per manufacturer’s instructions, can ensure low friction and consequently, less wear.

Maintaining the Slip Ring Sensors’ durability is pivotal to the long-term success of any application they are part of. Timely maintenance, inspections, and adherence to manufacturer’s instructions can go a long way in preserving their performance, thereby safeguarding their contribution to the seamless functioning of various technological systems.

User Concerns and Troubleshooting of Slip Ring Sensors

As users implement Slip Ring Sensors in various applications, it’s not uncommon for them to encounter issues or have concerns about these powerful tools.

Common User Concerns

Lifespan Worries

Users often raise concerns about the sensors’ lifespan, especially in harsh operating environments.

Noise and Interference

Another common concern is related to electrical noise and signal interference, leading to data or signal distortion.

Installation

The correct installation process is a frequent question among users, and accurate orientation and alignment during installation are crucial to guarantee optimal performance.

Troubleshooting Common Issues

Signal Disturbance

If there’s a noticeable signal disturbance, users need to first check the integrity of the connections. Loose connections often cause such problems. If the issue persists, it may indicate worn-out contact materials that need replacement.

Reducing Lifespan

If the unit seems to exhibit reduced lifespan or performance, it may be due to excessive RPM or harsh environmental conditions. Consulting the manufacturer’s specified limits for operation is key in such situations.

Wear and Tear

Signs of excessive wear and tear might be indicative of misalignments or overloading. Checking the installation for any misalignments or ensuring that the loads are within specified limits could help resolve these issues.

Choosing Good-Quality Slip Ring Sensors

Manufacturer Reputation

Always look for a reputable manufacturer when buying these sensors. Reviews and recommendations can be valuable resources for understanding the quality of the products.

Know Your Requirements

The best way to ensure high quality is to understand your specific requirements. This goes for the type of sensor, its capacity, speed limitations, and other operational parameters like temperature and humidity resistance.

Seek Professional Guidance

When in doubt, users should not shy away from seeking professional advice. Experts and experienced professionals can provide proper guidance based on specific applications.

Overall, even though issues with Slip Ring Sensors might arise, through proper troubleshooting, users can effectively resolve many common problems. Also, by acquiring quality devices that suit their specific needs, users can benefit the most from these versatile and robust sensors.

Conclusion

Slip Ring Sensors, the unsung heroes of many industries, are truly a marvel of contemporary engineering. Their applications and functionality have proven to be an indispensable part of modern society, despite being largely unnoticed. When choosing a Slip Ring Sensor, users must consider their specific needs and requirements. The sensor’s build quality, brand reputation, and its specifications should align with these needs, ensuring long-term efficiency and reliability.

See What We Can Do