The use of slip rings and brushes in industrial applications is far from obsolete. In fact, engineers and scientists of the future will continue to rely on technology to move energy, power, and data from stationary to mobile applications. They are an important part of industrial applications, and their use will remain so in the future. This article will discuss the future of brushes and slip rings in industrial applications.

What Are Slip Rings and Brushes

Slip ring brushes are a type of electrical contact system used to transfer electricity, data, or signals from a stationary to a rotating system. The slip ring is a rotating electrical contact device mounted onto a stationary shaft, while the brushes are sliding contacts that brush against the slip ring. This creates an electrical connection that allows power, data, or signals to be transferred between the stationary and rotating systems. The slip ring and brush assembly work together to create a continuous electrical connection between the two components. The brush slip ring and slip ring brush assembly are some of the key components for slip rings.

Types of Slip Rings and Brushes

Types of Slip Rings

- Capsule Slip Rings

- Description: Small, compact slip rings used primarily in devices where space is limited.

- Applications: Medical equipment, small robots, and instrumentation.

- Through Bore Slip Rings

- Description: Feature a central hole (bore) allowing other components like fluid or pneumatic lines to pass through.

- Applications: Wind turbines, rotary tables, and robotic arms.

- High Current Slip Rings

- Description: Designed to handle high electrical currents, often featuring larger contact surfaces.

- Applications: Heavy machinery, cranes, and industrial equipment.

- Fiber Optic Rotary Joints (FORJs)

- Description: Use optical fibers to transmit data at high speeds and large bandwidths.

- Applications: Telecommunications, medical imaging, and military systems.

- Pancake Slip Rings

- Description: Flat, disk-shaped slip rings used where vertical space is limited but there is more horizontal space.

- Applications: Radar systems, packaging machines, and rotating tables.

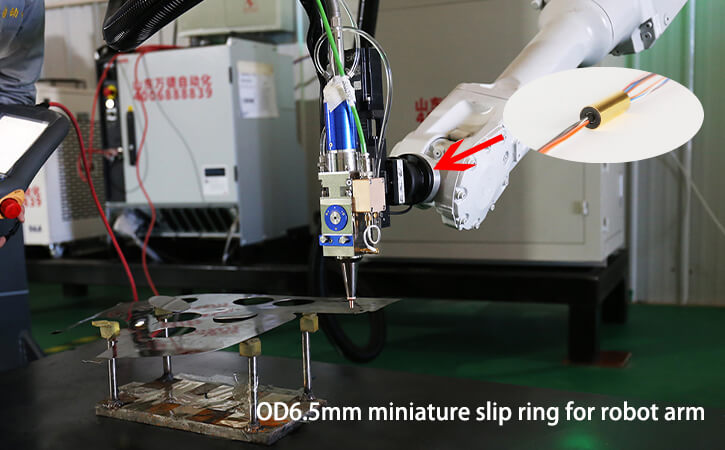

- Miniature Slip Rings

- Description: Very small slip rings designed for applications with tight space constraints.

- Applications: Drones, precision instruments, and small robotics.

- High Temperature Slip Rings

- Description: Built to withstand extreme temperatures, either very high or very low.

- Applications: Aerospace, defense, and industrial furnaces.

Types of Brushes

- Carbon Brushes

- Description: Made from carbon, these brushes are commonly used due to their good conductivity and self-lubricating properties.

- Applications: Electric motors, generators, and alternators.

- Graphite Brushes

- Description: Provide better lubrication and lower friction, reducing wear on both the brush and slip ring.

- Applications: Power tools, industrial machinery, and traction motors.

- Metal-Graphite Brushes

- Description: Combine metal’s conductivity with graphite’s lubrication, suitable for high-load and high-speed applications.

- Applications: Commutators in high-power motors and generators.

- Electrographite Brushes

- Description: High-temperature brushes made from treated carbon, ideal for high-voltage and high-current applications.

- Applications: Steel mills, electric locomotives, and large industrial motors.

- Resin-Bonded Brushes

- Description: Carbon and graphite brushes bonded with resin, offering higher strength and stability.

- Applications: Variable speed motors, industrial fans, and blowers.

- Copper-Graphite Brushes

- Description: Composed of copper and graphite, these brushes are excellent for high current densities and low voltage drops.

- Applications: Welding generators, turbo generators, and slip ring motors.

The Materials Used in the Manufacture of Slip Rings and Brushes

The materials used in the manufacture of slip ring brushes include a variety of metals, ceramics, and graphite. The metals used depend on the application and the desired performance characteristics. Commonly used slip ring brush material includes copper, silver, gold, aluminum, and stainless steel. The metal is usually plated with a conductive material such as tin, nickel, or gold. The ceramic material is used to provide insulation and reduce wear on the brush. Graphite is also used in some applications to provide a low-friction contact surface.

The brushes are usually constructed from carbon or graphite fibers, which are bonded together and mounted on a conductive spring or a metal shank. The fibers are usually coated with a conductive material such as silver, gold, or copper to provide good electrical contact. In some cases, the fibers may be impregnated with a lubricant to reduce wear and tear on the brush.

The slip ring is usually made from an insulating material such as ceramic, glass, or plastic. The slip ring is usually mounted on a shaft and is connected to the stationary part of the machinery. The shaft is usually made from a metal such as steel or aluminum, and the slip ring is rotated by a motor or a gearbox.

The assembly of a slip ring brush is a complex process, and the quality of the components and the assembly is critical to its performance. The materials used in the manufacture of slip ring brushes must be carefully selected to ensure that they are suitable for the application and provide the required performance characteristics.

The function of Slip Rings and Brushes

Slip rings and brushes are components of a rotary electrical contact system. Slip rings are metal rings with an electrically conductive surface, typically made of copper, that allow for the transmission of electricity and data signals from a stationary component to a rotating component. Brushes are stationary components that contact the slip rings, allowing an uninterrupted electrical connection between the stationary and rotating parts.

They are commonly used in motors, generators, and electrical transformers. They are also used to provide power and signals to antennas, radar systems, and other rotating equipment. In short, they are used to provide an uninterrupted electrical connection between stationary and rotating components.

Slip Rings and Brushes in Industrial Applications

Advantages of Slip Rings and Brushes

There are many advantages of slip rings and brushes, including:

1. Durability: They are designed to last for a long time. They are built with durable materials and can withstand continued use.

2. Low Maintenance: They require minimal maintenance and can be used for years without requiring replacement.

3. High Efficiency: They provide high-efficiency power transfer from the stationary to the rotating component.

4. Low Friction: They provide low friction, which helps reduce wear and tear on the components.

5. Cost Effective: They are cost-effective and can be used in a variety of applications.

Maintenance Tips of Slip Rings and Brushes

Maintenance Tips for Slip Rings

- Regular Inspection

- Visual Check: Inspect the slip rings for signs of wear, corrosion, and surface irregularities.

- Operational Check: Monitor for any unusual noises or vibrations during operation which could indicate wear or alignment issues.

- Cleaning

- Debris Removal: Use a soft brush or compressed air to remove dust and debris from the slip ring assembly.

- Surface Cleaning: Clean the slip ring surface with isopropyl alcohol and a lint-free cloth to remove any built-up contaminants.

- Lubrication

- Use Appropriate Lubricants: Apply manufacturer-recommended lubricants to reduce friction and wear.

- Avoid Over-Lubrication: Excessive lubrication can attract dust and debris, causing more harm than good.

- Alignment Check

- Proper Installation: Ensure slip rings are properly aligned during installation to avoid uneven wear.

- Periodic Adjustment: Regularly check and adjust the alignment as needed to maintain optimal contact.

- Environmental Protection

- Sealing: Use protective seals or covers to keep out dust, moisture, and other contaminants.

- Temperature Control: Ensure the operating environment is within the temperature range specified by the manufacturer.

- Electrical Contact Maintenance

- Contact Pressure: Ensure that the brushes maintain appropriate pressure against the slip ring surface for consistent contact.

- Replace Worn Brushes: Regularly inspect and replace brushes that show significant wear or damage.

Maintenance Tips for Brushes

- Regular Inspection

- Wear Monitoring: Check brushes for wear and replace them when they reach the manufacturer’s recommended minimum length.

- Surface Condition: Inspect the brush surface for cracks, chips, or other signs of damage.

- Cleaning

- Brush Holders: Clean brush holders to remove dust and debris that could interfere with brush movement.

- Contact Area: Clean the contact area of the brush and slip ring to ensure good electrical contact.

- Lubrication

- Proper Lubrication: Apply appropriate lubricants to the brush contact area if recommended by the manufacturer.

- Avoid Contamination: Ensure that lubricants do not contaminate the slip ring surface or other components.

- Adjustment and Alignment

- Brush Spring Tension: Check and adjust the tension of brush springs to ensure proper contact pressure.

- Alignment: Ensure brushes are properly aligned with the slip ring to avoid uneven wear and sparking.

- Replacement

- Timely Replacement: Replace brushes at regular intervals or when they show signs of excessive wear or damage.

- Use Correct Brushes: Always use manufacturer-recommended brushes to ensure compatibility and performance.

- Electrical Contact Maintenance

- Minimize Sparking: Regularly inspect and clean to minimize sparking, which can cause pitting and damage.

- Monitor Performance: Keep track of brush performance, such as changes in voltage drop or current flow, which could indicate wear or other issues.

General Best Practices

- Follow Manufacturer Guidelines: Always adhere to the maintenance schedules and guidelines provided by the slip ring and brush manufacturers.

- Record Keeping: Maintain detailed records of maintenance activities, inspections, and replacements to track performance and predict future maintenance needs.

- Training: Ensure maintenance personnel are properly trained on the specific requirements and procedures for the slip rings and brushes in use.

- Preventive Maintenance: Implement a preventive maintenance program to address potential issues before they lead to equipment failure.

Regular and proactive maintenance of slip rings and brushes can significantly extend their lifespan, improve performance, and reduce the likelihood of unexpected equipment failures.

Future of Slip Rings and Brushes

The future of slip rings and brushes is bright, as they are becoming increasingly important components in a wide range of applications. With the development of new technologies, there is a growing demand for more sophisticated brushes that are able to meet the requirements of modern applications. For example, they are increasingly being used in applications such as robotics, aerospace, and wind turbines, where high-precision and reliable power and data transmission are required. Slip rings and brushes are also continuing to be used in traditional applications such as military, marine, and medical equipment.

In the future, it is expected that the demand for them will continue to increase, as more industries look to integrate them into their designs. Advances in material science and computer-aided design are also allowing for the development of more sophisticated and reliable slip rings and brushes, such as PCB slip rings. As a result, it is likely that they will become even more reliable and versatile in the future.

Slip rings and brushes are an important part of industrial applications, and their use will remain so in the future. As technology advances, brushless slip rings and new materials for slip rings and carbon brushes are becoming more popular. This will allow engineers and scientists to create more reliable and efficient industrial applications.

See What We Can Do