In this article, we delve into the world of slip rings and carbon brushes, exploring their fundamental purpose, historical evolution, operating principles, practical applications, and technological advancements. By addressing common user concerns, we aim to demystify these essential components that ensure smooth electrical connections across a variety of sectors.

Introduction to Slip Rings and Carbon Brushes

In the realm of electromechanical systems, ensuring a seamless transfer of power and data is paramount, especially in applications involving rotational movement. This is where slip rings and carbon brushes come into play, serving as the backbone for continuous electrical conductivity between stationary and moving parts.

What are Slip Rings and Carbon Brushes?

Slip rings are electromechanical devices designed to transmit electrical power or signals between a stationary structure and a rotating one. Imagine a ring composed of a conductive material, mounted on a rotating shaft. As the shaft turns, the ring remains in constant electrical contact with a stationary circuit, thanks to the carbon brushes that press against it.

Carbon brushes, on the other hand, are small blocks of carbon or graphite, engineered to conduct electricity. They are held in place by a spring mechanism, ensuring they remain in contact with the slip ring’s outer surface. As the ring rotates, these brushes slide over its surface, facilitating the transfer of electrical currents or signals from the stationary part to the rotating part or vice versa.

Significance of Slip Rings in Rotary Electrical Interfaces

In any electromechanical system that requires rotation, maintaining an uninterrupted electrical connection is a critical challenge. Without slip rings, transmitting power and signals to a rotating platform would entail tangled wires or frequent disconnects, leading to inefficient operations and the potential for significant mechanical wear. Slip rings solve this conundrum by offering a reliable, rotating interface that can handle continuous electrical transfer without hindering the movement of the components involved.

Carbon Brushes as a Key Component in Maintaining Electrical Conductivity

The efficacy of slip rings is heavily reliant on the performance of carbon brushes. These brushes are the direct contact points that enable the flow of electricity, acting as the mediators translating stationary energy into rotational action. The materials used for carbon brushes — typically graphite or a graphite-copper composite — are chosen for their excellent conductive properties, low friction, and high resistance to electrical and mechanical wear. This ensures that the electrical connection remains stable and consistent, even under the stress of high-speed rotations.

The symbiotic relationship between slip rings and carbon brushes is fundamental to the operation of a myriad of devices across various industries. From enabling the transmission of power to wind turbine blades to ensuring that data can be transmitted from moving radar antennas, the combination of slip rings and carbon brushes is indispensable for modern electromechanical systems. Their proper design, installation, and maintenance are thus crucial for the seamless operation of machinery where rotational motion and electrical connectivity must coexist harmoniously.

Slip Rings and Carbon Brushes Historical Context

The history of slip rings and carbon brushes is a narrative of ingenuity and the relentless pursuit of efficiency in electrical engineering. Each step in their evolution reflects broader advancements in technology and a growing understanding of materials science and electromechanical system design.

A Brief History of Slip Rings and Carbon Brushes

The origins of slip rings and carbon brushes can be traced back to the pioneering days of electrical machines in the 19th century. These early versions were rudimentary and were quickly recognized as an area needing improvement for the budding field of electrical engineering. As electrical motors and generators became more commonplace, the demand for reliable and enduring contact between stationary and moving parts grew, leading to the development of the slip ring and carbon brush assembly we recognize today.

The carbon brush made its debut as a way to resolve issues caused by metal brushes, which included excessive wear and sparking due to high friction. Carbon brushes, with their superior electrical conductivity and lower friction, proved to be a major leap forward, extending the life of the components and reducing maintenance needs.

Evolution of Their Designs and Materials

Initially, slip ring assemblies utilized materials that were readily available at the time, such as copper and brass, which possess good conductivity but also come with inherent challenges like corrosion and wear under high-current conditions. Carbon brushes often featured a simple block of copper wire-wrapped carbon, but as electrical currents grew larger and systems spun faster, the need for more refined materials became clear.

Over time, with deeper insights into material properties and improvements in manufacturing techniques, design sophistication grew. Manufacturers began incorporating new alloys and composites to better serve the diverse applications of slip rings and brushes. For instance, silver alloyed slip rings emerged for high-performance applications requiring superior conductivity and minimal noise, while carbon brushes evolved into carefully composed blends of copper graphite, improving lifespan and conductivity.

Materials like graphite allowed for self-lubrication, which significantly cut down on the wear and tear associated with the brushes sliding over the slip rings’ surfaces. The introduction of metal-graphite brushes enhanced the performance parameters, offering optimal solutions for both high-load applications and those requiring precise signal transmission.

The transformations over the years have been guided by an intricate understanding of the demands placed on slip rings and brushes in various industrial environments. The need to operate at high speeds, under significant electrical loads, and environmental conditions such as extreme temperatures and exposure to corrosive elements has driven the material and design evolution.

The culmination of these developments is embodied in the modern slip ring and carbon brush: a finely-tuned set of devices designed with a close eye on material wear characteristics, electrical and thermal conductivity, mechanical stability, and overall durability. From immense turbines harnessing the power of the wind to the precise instruments used in medical equipment, the historical context of slip rings and carbon brushes is one of continuous improvement and sophistication, mirroring the trajectory of the broader advancements in engineering and materials science.

Slip Rings and Carbon Brushes: Mechanical and Electrical Principles

Exploring the world of slip rings and carbon brushes requires an understanding of both mechanical movement and electrical conduction. The conjunction of these two domains helps elaborate on how these devices collaborate to transmit power or data across rotating interfaces, offering a compelling study of physics in action.

How Slip Rings and Carbon Brushes Work Together

At its core, a slip ring is a conductive ring mounted onto a rotating shaft. The carbon brush, held by a spring-loaded setup, makes contact with the outer surface of the rotating slip ring. As the shaft and ring rotate, the brush maintains a continuous electrical connection by “slipping” over the surface of the ring.

Even though the ring and brush are constantly in motion relative to one another, the electrical connectivity between them remains unbroken. This unbroken chain forms an electrical pathway between the stationary and rotating parts, enabling power and signals to flow seamlessly.

The performance characteristics of the carbon brush and its holder—like pressure, coefficient of friction, resulting wear, and operating temperature—are all critical considerations. A delicate balance of these factors is important to ensure minimal resistance to electrical flow while also maximizing the service life of both the brush and ring.

The Physics of Transferring Power or Data across Rotating Interfaces

The mechanical principle driving the functionality of slip rings and carbon brushes is fairly simple: The brush, pressed gently against the rotating ring, maintains physical contact throughout the rotation, allowing for efficient power transmission. This is possible thanks to the low-friction and high-conductivity characteristics of the materials used, such as copper or graphite.

On the electrical front, the principle of electromagnetic induction is key to understanding the transfer of electrical power or data. The electricity flows through the carbon brush to the slip ring, creating a magnetic field around the conductive material. This magnetic field induces an electrical current in the ring, effectively transferring the power from the stationary brush to the rotating ring or vice versa.

For data transmission, slip rings and carbon brushes work analogously to power transmission. However, instead of transferring raw power, signals are conveyed in the form of voltage or current variations. These changes are then interpreted into usable data by the receiving electronics. Fluctuations in these signals need to be minimized, requiring the use of materials and designs that ensure maximum conductivity along with minimal electrical noise.

The dance of slip rings and carbon brushes demonstrates a wonderful intermingling of physics. The mechanical principles of movement, coupled with the electrical principles of conduction and induction, come together to make possible the uninterrupted transfer of power or data. This collaboration plays an essential role in a vast array of systems ranging from simple electric motors to complex wind turbines and communication antennas.

Slip Rings and Carbon Brushes: Common Applications

Slip rings and carbon brushes are ubiquitous in machinery that require the transfer of electricity between stationary and moving parts. They are often unnoticed, yet key components in a plethora of equipment and systems. This section will delve into their use in industrial machinery, wind turbines, automotive alternators, and electrical generators and motors.

Industrial Machinery

Many types of industrial machinery require rotation for their normal operation. Examples include packaging machines, molding machines, centrifuges, rotary tables, and robotic arms. In all these applications, slip rings and carbon brushes play a crucial role in ensuring smooth power supply or signal transmission between stationary controls and movable parts. They ensure the functionality of rotating sensors, cameras, actuators, or other key components that need reliable electrical connection during their rotational movement.

Wind Turbines

Wind turbines exemplify the use of slip rings and carbon brushes in renewable energy systems. Here, the blades of wind turbines rotate under the influence of wind, driving the generator to produce electricity. The slip ring is incorporated into the main shaft, transferring the generated power from the rotating generator to the stationary grid system. The carbon brushes facilitate this power transfer, ensuring that despite the constant movement of the turbine, the generated power is seamlessly delivered to the grid.

Automotive Alternators

Automotive alternators are responsible for providing power to an automobile’s electrical components and charging the battery. Inside an alternator, an electromagnet spins within a stator to generate electricity. This electricity needs to be transferred from the rotating electromagnet to the vehicle’s stationary electrical system for use. For this transfer, a slip ring and brush assembly are used. Carbon brushes feed power to the rotating magnet and also transfer the generated electricity back to the alternator’s stationary components – a critical role without which an automobile’s electrical system would not function efficiently.

Electrical Generators and Motors

In electrical generators and motors, slip rings, and carbon brushes allow electrical connections to be made and power or signals to be exchanged between stationary and rotating parts. For motors, brushes and slip rings supply the rotating coil with electric current, a fundamental requirement for the operation of electric motors. In generators, similarly, the current generated by the rotating coil is transferred to the output terminals through slip rings and brushes.

The key aspect in all these applications is to maintain electrical continuity while still allowing mechanical rotation, and it is precisely here that slip rings and carbon brushes shine. The harmony they create between rotational motion and electrical connectivity makes them a vital part of a multitude of devices and systems. By understanding their application in different contexts, the importance of these humble components in everyday life comes into clear focus.

What Is The Use of Slip Rings And Carbon Brushes

Slip Rings

Slip rings are electromechanical devices used to transmit electrical power and signals from a stationary component to a rotating component. They are commonly used in applications where continuous rotation is necessary, such as in:

- Wind Turbines: Slip rings allow the transmission of power and signals from the rotating blades to the stationary nacelle.

- Cranes and Hoists: They provide electrical power to rotating platforms.

- Rotary Tables: Used in manufacturing for continuous rotation and transmission of control signals.

- Medical Imaging: Slip rings are crucial in MRI and CT scanners for transmitting power and signals to the rotating imaging equipment.

- Radar and Antenna Systems: They enable continuous rotation and data transmission.

- Robotics: Slip rings ensure power and data transmission in robotic arms with rotational joints.

Carbon Brushes

Carbon brushes are components used to conduct electrical current between stationary wires and rotating machinery parts. They are commonly found in:

- Electric Motors: Carbon brushes transfer current from the stationary part of the motor to the rotating part, enabling the motor to function.

- Generators: They conduct electrical current from the rotating armature to the external circuit.

- Alternators: Used in automotive alternators to provide electrical power for the vehicle’s electrical systems.

- Slip Rings: In conjunction with slip rings, carbon brushes are used to maintain electrical contact and ensure smooth operation in rotating systems.

- Power Tools: Many power tools, such as drills and saws, use carbon brushes to transfer current to the rotating parts.

Combined Use

In many applications, slip rings and carbon brushes work together to ensure reliable transmission of electrical power and signals in systems requiring continuous rotation. The carbon brushes maintain contact with the rotating slip ring, allowing the electrical current to pass through despite the rotation.

Advantages of Using Slip Rings and Carbon Brushes

- Continuous Operation: They enable continuous 360-degree rotation without the need for wires that could twist or break.

- Signal Integrity: Ensure stable transmission of power and data signals.

- Durability: Designed to withstand wear and tear, ensuring long-term reliability.

- Versatility: Applicable in a wide range of industries and applications, from heavy machinery to delicate medical equipment.

What is the Role of the Slip Rings and Carbon Brushes in the Electrical Gadgets?

Role of Slip Rings in Electrical Gadgets

Slip rings are critical components in electrical gadgets that require continuous rotation while maintaining electrical connections. Their roles include:

- Continuous Rotation Transmission

- Function: Allow for uninterrupted power and signal transmission between stationary and rotating parts.

- Example: In a wind turbine, slip rings transmit electrical power from the rotating blades to the stationary electrical grid.

- Reducing Mechanical Stress

- Function: Minimize wear and tear on wires by providing a rotating connection.

- Example: In a CT scanner, slip rings enable the continuous rotation of the X-ray tube while transmitting power and data, reducing mechanical stress on cables.

- Enabling Compact Designs

- Function: Facilitate compact and efficient designs by integrating power and signal transmission into rotating systems.

- Example: In robotic arms, slip rings allow for continuous rotation and control without complex cable management.

- Maintaining Reliability

- Function: Ensure reliable transmission of electrical signals and power in rotating systems.

- Example: In radar systems, slip rings maintain stable signal transmission to rotating antennas.

Role of Carbon Brushes in Electrical Gadgets

Carbon brushes are essential for conducting electrical current between stationary and rotating parts. Their roles include:

- Electrical Current Transmission

- Function: Conduct electrical current from a stationary component to a rotating component.

- Example: In electric motors, carbon brushes transfer current to the rotating armature, enabling motor operation.

- Maintaining Contact

- Function: Provide consistent electrical contact with rotating parts, such as commutators or slip rings.

- Example: In power tools, carbon brushes maintain contact with the motor’s commutator, ensuring smooth operation.

- Wear Resistance

- Function: Serve as replaceable contact points that wear down over time instead of more expensive parts.

- Example: In household appliances like washing machines, carbon brushes are designed to be easily replaceable, extending the life of the motor.

- Efficient Energy Transfer

- Function: Enable efficient transfer of electrical energy in rotating systems.

- Example: In automotive alternators, carbon brushes ensure efficient power generation by maintaining contact with the rotating slip rings.

Summary

- Slip Rings:

- Allow continuous rotation while transmitting electrical power and signals.

- Reduce mechanical stress on cables and wires.

- Enable compact and efficient designs in various devices.

- Carbon Brushes:

- Conduct electrical current between stationary and rotating parts.

- Ensure consistent electrical contact and efficient energy transfer.

- Provide durable and replaceable contact points in electrical gadgets.

Both slip rings and carbon brushes are crucial for the smooth and reliable operation of many electrical gadgets and systems, from industrial machinery to household appliances.

Types of Slip Rings And Carbon Brushes

Types of Slip Rings

- Through Bore Slip Rings

- Description: These slip rings have a hole through the center, allowing for the passage of other components, such as a shaft or cable.

- Applications: Wind turbines, packaging machines, rotary tables.

- Capsule Slip Rings

- Description: Compact slip rings designed for space-limited applications.

- Applications: CCTV systems, medical equipment, robotics.

- Pancake Slip Rings

- Description: These slip rings have a flat, disc-like shape, suitable for applications with height restrictions.

- Applications: Medical imaging systems, aerospace applications, rotary platforms.

- High-Temperature Slip Rings

- Description: Designed to operate in environments with extreme temperatures.

- Applications: Industrial furnaces, aerospace applications, oil and gas drilling.

- Ethernet Slip Rings

- Description: Specialized for transmitting Ethernet signals along with power.

- Applications: Surveillance systems, automation, robotics.

- Fiber Optic Rotary Joints (FORJ)

- Description: Used for transmitting optical signals in applications requiring high-speed data transmission.

- Applications: Telecommunications, medical imaging, military and aerospace.

- Hydraulic Rotary Joints

- Description: Combine slip rings with hydraulic channels to transmit fluid and electrical signals.

- Applications: Construction equipment, industrial machinery, automation.

Types of Carbon Brushes

- Graphite Carbon Brushes

- Description: Made of natural or artificial graphite, providing excellent lubrication properties.

- Applications: High-speed tools, small motors.

- Electrographite Brushes

- Description: Treated to enhance hardness and conductivity, suitable for heavy-duty applications.

- Applications: Industrial motors, generators, slip rings.

- Metal-Graphite Brushes

- Description: Contain a mix of graphite and metal powders (usually copper), providing high conductivity.

- Applications: Commutators, slip rings in heavy machinery.

- Carbon Graphite Brushes

- Description: Made from a mix of carbon and graphite, suitable for general-purpose use.

- Applications: Automotive motors, power tools.

- Resin-Bonded Carbon Brushes

- Description: Carbon brushes bonded with a resin, providing good performance and durability.

- Applications: Fractional horsepower motors, appliances.

- Silver-Graphite Brushes

- Description: Incorporate silver to enhance conductivity and performance in low voltage applications.

- Applications: Precision instruments, aerospace applications.

Visual Representation

Here’s a simplified illustration of different types of slip rings and carbon brushes:

- Through Bore Slip Ring: A cylindrical ring with a central hole.

- Capsule Slip Ring: A small, compact cylindrical unit.

- Pancake Slip Ring: A flat, disc-shaped ring.

- High-Temperature Slip Ring: A robust ring with heat-resistant materials.

- Ethernet Slip Ring: A ring with multiple channels for Ethernet cables.

- Fiber Optic Rotary Joint: A ring with optical fiber connectors.

- Hydraulic Rotary Joint: A ring with fluid channels and electrical contacts.

Carbon Brushes:

- Graphite Brush: A rectangular or cylindrical piece of graphite.

- Electrographite Brush: A treated, durable brush with enhanced conductivity.

- Metal-Graphite Brush: A mix of metal and graphite particles.

- Carbon Graphite Brush: A blend of carbon and graphite materials.

- Resin-Bonded Brush: A brush with resin for bonding the carbon particles.

- Silver-Graphite Brush: A brush with silver particles for high conductivity.

Slip Rings and Carbon Brushes: Materials and Design

The effectiveness of slip rings and carbon brushes in transferring power and signals across rotating interfaces hinges on the materials from which they are made and their specific design considerations. The diversity in applications across various industries necessitates a wide range of materials, each with its unique set of properties tailored to meet different operational demands.

Types of Materials Used for Slip Rings and Carbon Brushes

Slip Rings: Commonly, slip rings are made from materials that exhibit excellent electrical conductivity, such as copper, brass, silver, or gold. In certain applications where durability and wear resistance are critical, alloys or composite materials may be used. For instance, gold-alloyed slip rings are often utilized in high-reliability applications such as aerospace or medical equipment due to their superior conductivity and resistance to corrosion.

Carbon Brushes: The materials used for carbon brushes vary considerably and typically include a blend of carbon, graphite, copper, and sometimes silver. Pure graphite brushes are known for their high conductivity while adding metal powders (like copper) can improve electrical properties and reduce contact resistance. The specific composition is carefully chosen based on the application’s requirements for conductivity, thermal management, and wear characteristics.

Advantages and Disadvantages of Different Materials

The choice of materials for slip rings and carbon brushes entails a careful balancing of benefits and potential drawbacks.

Copper and Brass Slip Rings:

- Advantages: Copper and brass are highly conductive, making them excellent choices for efficient power transfer. They are also relatively easy to machine and widely available, which helps in keeping costs down.

- Disadvantages: These materials can tarnish or corrode over time, especially in harsh environments, potentially leading to increased electrical resistance and reduced system efficiency.

Gold and Silver Alloy Slip Rings:

- Advantages: These materials offer superb electrical conductivity and are highly resistant to corrosion, making them ideal for critical applications in harsh or highly variable environments.

- Disadvantages: The primary downside is cost, both in terms of the raw materials and the processing required to utilize them effectively in slip ring applications.

Graphite and Carbon Brushes:

- Advantages: Pure graphite brushes provide excellent conductivity and natural lubricating properties, reducing wear on both the brush and the slip ring. Additionally, they can operate at high temperatures without significant degradation.

- Disadvantages: Pure graphite brushes may not be as durable as metal-infused alternatives under high-load conditions or where varying contact forces are involved.

Copper-Graphite Brushes:

- Advantages: Incorporating copper into the graphite matrix can enhance conductivity and wear characteristics, making these brushes suitable for heavy-duty applications.

- Disadvantages: The addition of copper reduces the natural lubrication properties of pure graphite, which can increase wear under certain conditions.

The optimal material choice for slip rings and carbon brushes depends on a complex interplay of factors, including the specific requirements of the application, cost constraints, and operational environment conditions. Understanding these trade-offs is critical for designers and engineers as they develop and refine electromechanical systems to meet ever-evolving performance and reliability standards.

Application of Slip Rings And Carbon Brushes

Slip Rings and Carbon Brushes: Installation and Maintenance

Installing and maintaining slip rings and carbon brushes maximizes the system’s operational longevity and effectiveness. Understanding how to approach the installation process and maintenance schedule, as well as troubleshooting common issues, is essential in exploiting these components’ full potential.

Step-by-step Guide on Installing Slip Rings and Carbon Brushes

The specifics of the installation process will vary depending on machine design, but the following presents a general guideline:

Step 1: Preparation

Ensure all components are clean, especially the contact surfaces. Clear away any dust, grime, grease, or debris.

Step 2: Installation of Slip Ring

Mount the slip ring to the shaft, aligning it according to the machine’s alignment requirements. Secure it properly, ensuring that it rotates freely and without flutter.

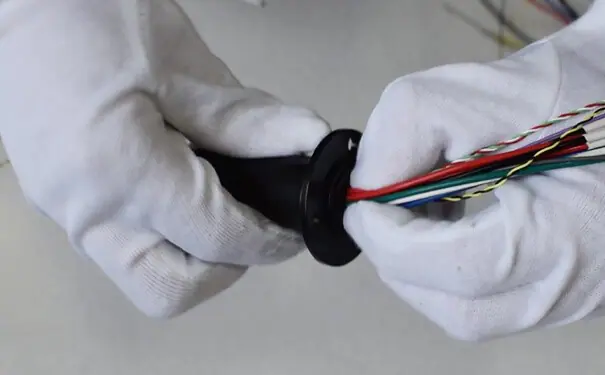

Step 3: Carbon Brush Placement

Insert the carbon brushes into their holders. Ensure that they slide freely and have the correct spring pressure. Too much pressure could cause excessive wear; too little may lead to poor electrical conductivity.

Step 4: Setting Up the Connections

Connect the wiring from the stationary electrical system to the carbon brushes and from the slip ring to the rotating equipment.

Step 5: Testing

Turn the system on and verify that it is operating properly by checking for current flow and the absence of excessive heat or noise.

Best Practices for Maintenance to Ensure Longevity

Maintenance is critical to extend the lifecycle of slip rings and carbon brushes and keep the systems operating at peak efficiency.

Regular Inspection: Check the wear on both the slip ring surface and the carbon brushes periodically. Each component should wear evenly; uneven wear may indicate issues with alignment or brush pressure.

Cleaning: Remove dust or debris from the assembly regularly. Accumulated material can impede the electrical connection and accelerate wear.

Replace Worn Parts: Carbon brushes and slip rings do not last forever and will wear out with use. For most machines, replacing these parts is a routine maintenance task that can significantly extend the overall lifespan of the equipment.

Troubleshooting Common Issues

Problems with slip rings and carbon brushes can manifest in various ways: overheating, excessive sparking, sudden drops in machine performance, etc. Here are some common issues and their possible fixes:

- Excessive wear or grooves on the slip ring or brush: This often indicates that the spring pressure on the brush is too high. Check the manufacturer’s recommendation and adjust as necessary.

- Insufficient electric contact (poor conductivity): This might be due to low spring pressure or accumulation of dirt or other debris. Clean the components and adjust the spring pressure if necessary.

- Overheating or excessive sparking: It can be a result of misalignment, high resistance due to dirt, or low spring pressure. Check the alignment adjustment, thoroughly cleanse the components, and verify the spring pressure.

Through a proactive approach towards installation, regular maintenance, and troubleshooting, the operational longevity and efficiency of slip rings and carbon brushes can be greatly enhanced. Despite the varied factors that can impact their performance, understanding and addressing each one sequentially can considerably mitigate potential issues and downtime.

Slip Rings and Carbon Brushes: Advances in Technology

Recent developments in slip ring and carbon brush technology have focused on extending their operational life, enhancing electrical conductivity, reducing maintenance, and addressing the specific needs of increasingly complex and high-speed machinery. These advancements reflect ongoing efforts to meet user demands for reliability, efficiency, and minimal downtime in various industrial applications.

Latest Innovations in Slip Ring and Carbon Brush Technology

These represent a leap in data transmission technology, allowing for the transfer of data at high speeds and volumes without electromagnetic interference that can plague traditional metallic slip rings. They utilize optical fibers to transmit signals, which is especially beneficial in environments susceptible to electromagnetic disturbances.

Employing inductive coupling techniques, wireless slip rings offer a contactless solution to power and data transmission. This innovation significantly reduces wear and tear since there are no physical contacts, leading to lower maintenance requirements and a longer lifespan.

Self-lubricating Carbon Brushes

Advances in materials science have led to the development of carbon brushes that incorporate lubricating materials, reducing friction and wear on both the brush and the slip ring. This innovation extends the maintenance intervals and overall lifetime of the components.

Integrated Slip Ring Sensors

The integration of sensors into slip rings allows for real-time monitoring of critical parameters such as temperature, humidity, and wear. This capability enables predictive maintenance strategies, where components can be serviced or replaced just before they are likely to fail, rather than on a fixed schedule or after a failure has occurred.

How These Innovations Address User Concerns

Reliability: With the introduction of fiber optic and wireless slip rings, users benefit from an increase in the reliability of data and power transmission across rotating interfaces. The elimination of physical contact points in wireless slip rings and reduced electromagnetic interference in fiber optic alternatives directly translate to fewer failures and operational disruptions.

Maintenance and Lifecycle Costs: Innovations such as self-lubricating carbon brushes and integrated sensors directly address user concerns regarding maintenance frequency and component lifespan. By reducing the need for regular maintenance and enabling predictive maintenance schedules, these technologies significantly reduce total ownership costs.

Data Integrity and Speed: The transition to fiber optic slip rings has brought about a revolution in terms of the volume and speed of data that can be exchanged between stationary and rotating platforms. This is particularly important in applications like high-speed data acquisition systems and advanced communication networks, where data integrity and speed are paramount.

Operational Efficiency: Overall, these technological advances contribute to greater operational efficiency. Improved reliability and reduced maintenance needs mean that machines can operate for longer periods without interruption, while enhanced data transmission capabilities support more sophisticated and high-performance operations.

The constant push for innovation in slip ring and carbon brush technology exemplifies the industry’s commitment to addressing end-user needs. By focusing on improving reliability, reducing maintenance, and leveraging advanced materials and integrated monitoring technologies, these advances ensure that slip rings and carbon brushes remain integral components in modern machinery, capable of meeting the demands of contemporary applications.

Slip Rings and Carbon Brushes: User Concerns and Custom Solutions

Durability, efficiency, and customization are at the forefront of user concerns when it comes to slip rings and carbon brushes. Industries require solutions tailored to the unique demands of their applications, which vary widely in terms of operational loads, environmental conditions, and performance requirements.

Durability and Lifespan Under Various Loads

User Concern: The primary user concern with slip rings and carbon brushes is their ability to withstand the stress of different operational loads without premature wear or failure. Various applications impose different Rotational Speeds, electrical loads, and environmental conditions that can significantly affect component life.

Custom Solutions: To address these concerns, manufacturers offer customized solutions like specific alloy compositions for high-load applications or designs featuring improved contact materials for high-speed operations. Brushes may also be impregnated with metal to increase their durability, while slip rings could be plated with harder metals or engineered with built-in cooling systems to dissipate heat more effectively.

Electrical Noise and Its Reduction

User Concern: Electrical noise can cause signal interference, data corruption, and overall system unreliability. In sensitive applications, such as medical equipment or precision testing instruments, reducing electrical noise is vital for the accuracy and reliability of the device.

Custom Solutions: To meet this need, innovations have included the use of noise-suppressing materials and shielded cables. Additionally, non-ferrous materials in the construction of slip rings reduce magnetic interference. Design enhancements like smoother contact surfaces and the implementation of advanced filtering technologies also help to minimize noise transmission.

Resistance and Efficiency Considerations

User Concern: Resistance leads to power loss and heating, which can reduce efficiency and affect the performance and lifespan of slip rings and brushes. Optimizing these components for minimal resistance is crucial, especially in power-sensitive applications.

Custom Solutions: Manufacturers have responded by crafting slip rings from materials with inherently low electrical resistance, such as silver or gold alloys. Brushes can be optimized with a composition that strikes a balance between low resistance and longevity, or with additives such as silver to enhance their conductivity.

Customization for Specific Applications

User Concern: One size does not fit all when it comes to slip rings and carbon brushes. Users often require components that are custom-engineered to fit specific operational parameters, including size constraints, environmental conditions, and specialized electrical requirements.

Custom Solutions: To accommodate unique needs, providers offer fully customizable slip ring and brush systems. Solutions may involve compact designs for space-restricted applications, weatherproofing for outdoor use, integrated sensors for smart monitoring, or specialized mounting options for unusual configurations. By offering such tailored services, manufacturers can ensure that their components integrate seamlessly with the customers’ equipment, thereby enhancing performance and reliability.

By closely working with users to understand their specific concerns and requirements, manufacturers can deliver custom solutions that directly address the durability, noise reduction, resistance, and efficiency needs of various applications. This collaborative approach in developing slip ring and carbon brush technology helps ensure that systems operate effectively under the precise conditions they will face.

Slip Rings and Carbon Brushes: Environmental and Safety Considerations

The use of slip rings and carbon brushes in diverse industrial applications necessitates an ongoing focus on health, safety, and environmental sustainability. The handling, disposal, and environmental impact associated with these components form an essential part of their production and life cycle.

Health and Safety When Handling and Disposing of Carbon Brushes

Health and Safety Concerns:

Exposure to carbon dust and the potential for electrical shock are core safety concerns when working with carbon brushes. Improper handling during replacement or maintenance can also lead to injuries.

Safety Measures:

Safety practices should include wearing appropriate personal protective equipment (PPE), such as gloves and eye protection when handling or maintaining brushes. Good ventilation helps keep the atmosphere free of carbon dust. Electrical safety should be paramount, and only trained, qualified personnel should work on electrical assemblies.

Disposal of worn-out carbon brushes must be handled cautiously. Many carbon brush materials are not hazardous; however, some may contain metals or other compounds that can be harmful if not disposed of correctly.

Disposal Best Practices:

For best disposal practices, users should:

- Follow local regulations and guidelines for hazardous waste disposal

- Consult the Material Safety Data Sheet (MSDS) provided by the manufacturer

- Consider recycling initiatives where these are feasible

Environmental Impact and Sustainability Measures

Environmental Impact Concerns:

The production and disposal of slip rings and carbon brushes may contribute to environmental pollution if not appropriately managed. It is essential to scrutinize the entire lifecycle of these components for potential environmental impacts while also considering the energy expended during their manufacture and operation.

Sustainability Measures:

Producers of these components have made several strides in reducing the environmental footprint, including:

- Pursuing efficiency in production processes to cut down on energy use and waste

- Using more sustainably sourced and recyclable materials in product construction

- Implementing take-back programs that allow for the recycling or proper disposal of products at the end of their life

- Prioritizing advances such as self-lubricating brushes, which cut down on the amount of material used over the component’s lifetime by extending its lifespan

Whether it involves handling, disposing, or the broader manufacturing processes, prioritizing safety and environmental considerations concerning slip rings and carbon brushes is crucial. The adoption of rigorous health, safety measures, and proactive environmental sustainability practices establishes good stewardship, ensuring a safe working environment and minimizing ecological impact.

Slip Rings and Carbon Brushes: Cost Implications

The financial implications of slip rings and carbon brushes are a critical consideration for businesses. The cost analysis involves both the initial setup and long-term operational costs. At the same time, numerous cost-effective alternatives and market variations influence purchasing decisions.

Cost Analysis for Initial Setup and Long-term Operations

Initial Setup Costs:

The cost of slip rings and carbon brushes can vary considerably, depending on their design, manufacturing materials, and technical capabilities. Some factors influencing the initial setup cost include:

- The type of slip ring – traditional contact slip rings, fiber-optic slip rings, or wireless slip rings.

- The complexity of the design – slip rings designed for specialized applications, or those requiring high data transfer rates or power handling capabilities, can be more expensive.

- The choice of carbon brush materials may alter the cost.

Long-term Operational Costs:

While the upfront cost of these components is a crucial factor, the long-term operational costs may overshadow the initial setup costs. These include maintenance costs, replacement parts, and the cost related to machine downtime when maintenance is being performed.

Advancements like self-lubricating carbon brushes, integrated sensors, and wireless slip rings can reduce these costs, offering higher upfront but significantly lower long-term expenses due to their increased lifespan, reduced maintenance requirements, and higher overall reliability.

Cost-effective Alternatives and Market Variations

Cost-effective Alternatives:

In some situations, cost-effective alternatives to traditional slip rings and carbon brushes might exist, such as wireless power solutions, optical rotary joints, or magnetic couplings, particularly in low-power applications. The appropriateness of these alternatives will depend on the specific requirements of the application, including power transfer, speed, and environmental conditions.

Market Variations:

Market variations can also impact the cost. Supplier location, brand reputation, specialized performance capabilities, and the cost of raw materials all contribute to the overall price of the components.

The ongoing development of the industry has also resulted in market variations, with different product offerings from manufacturers around the world. For example, manufacturers in one region might focus on high-tech solutions like fiber-optic slip rings, while others might specialize in more traditional contact-based slip ring designs at a lower price point.

An understanding of the cost implications involving slip rings and carbon brushes is vital for businesses to make informed decisions. This knowledge, combined with awareness of both the initial setup costs and long-term maintenance and operation costs, aids in selecting the most cost-effective solutions that meet the demands of specific applications.

Slip Rings and Carbon Brushes: Future Trends

The landscape of slip ring and carbon brush technology is ever-evolving, shaped by advancements in materials science, and electronics, and a drive towards more efficient and sustainable power transmission systems. Predictions of these critical components focus on innovation, efficiency, and the potential for emerging technologies to reshape traditional models.

Predictions of Slip Ring and Carbon Brush Technology

Innovative Materials and Designs:

Future developments in slip ring and carbon brush technology are likely to leverage new materials and design methodologies to overcome current limitations. Innovations might include:

- Advanced Composite Materials: This includes the use of carbon nanotubes or graphene-infused compounds that offer superior conductivity, durability, and resistance to wear, potentially extending the operational life of these components significantly.

- Integrated Sensing and IoT Connectivity: Future slip rings and brushes could incorporate sensors and connectivity options to monitor wear and performance in real-time, allowing for predictive maintenance and minimizing downtime.

Increased Efficiency and Miniaturization:

- As devices and machinery continue to shrink in size but grow in complexity and power needs, the demand for compact, high-performance slip rings and brushes will increase. This could lead to the development of smaller, yet more efficient designs capable of handling higher data and power loads.

Potential Phase-Out and Replacement Technologies

Emergence of Wireless Power Transfer Systems:

- The future may see an increased adoption of wireless power transfer systems, particularly in applications where contactless operation could offer significant advantages in reliability, maintenance, and performance. While only suitable for some current slip ring and carbon brush applications, this technology might phase out the need for physical contact in power and data transmission in certain areas.

Optical and Magnetic Interfaces:

- Optical Technologies: For high-speed data transfer applications, future trends might lean towards optical slip rings that use light to transmit data, eliminating electrical interference and offering vastly superior data rates.

- Magnetic Couplings: In power transmission, magnetic couplings could offer a non-contact method to transfer power through magnetic fields, potentially reducing wear and maintenance needs.

Environmental Considerations:

- Future technologies might favor solutions that are more environmentally friendly, both in manufacturing processes and in operation. This could include the development of components from renewable resources or more easily recyclable materials, as well as designs that minimize energy loss and improve system efficiency.

Given these future trends, the landscape of slip ring and carbon brush technology is set for significant shifts. While traditional slip rings and brushes will likely remain pivotal in many applications due to their proven reliability and cost-effectiveness, the advancement towards more sophisticated, efficient, and environmentally sustainable technologies indicates a bright and innovative future for power and data transmission solutions.

Conclusion

Though often overlooked, slip rings and carbon brushes hold significance in varied applications. By staying abreast of advancements, ensuring regular maintenance, considering environmental impacts, and addressing cost implications, one can leverage these vital components’ full potential.

FAQs about Slip Rings and Carbon Brushes

Q: What are slip rings and carbon brushes used for?

A: Slip rings and carbon brushes are components used in electromechanical systems to transmit power and electrical signals from a stationary part to a rotating part. They are commonly found in motors, generators, wind turbines, and various rotating machinery where a continuous electrical connection is necessary during rotation.

Q: How do slip rings and carbon brushes work together?

A: Slip rings are conductive rings attached to a rotating shaft, while carbon brushes are stationary blocks that press against the rings. As the slip rings rotate, the brushes maintain electrical contact, allowing current to pass through from a static source to the rotating part, thereby ensuring a consistent electrical path.

Q: What materials are used to make slip rings and carbon brushes?

A: Slip rings are typically made from metals such as copper or silver alloys due to their excellent conductivity. Carbon brushes are usually composed of graphite, copper-graphite, or silver-graphite materials to provide good conductivity and minimal wear to the slip rings.

Q: Can slip rings transfer data as well as power?

A: Yes, slip rings can be designed to transfer electrical power and signals, including data for communication protocols such as Ethernet. Specialized slip rings called rotary joints or rotary electrical interfaces can manage complex signal and data transmission with minimal noise and interference.

Q: Are there maintenance requirements for slip rings and carbon brushes?

A: Yes, regular maintenance is crucial for optimal performance. This typically includes cleaning slip rings to remove debris and prevent the build-up of contaminants, inspecting carbon brushes for wear, ensuring proper tension is maintained, and replacing brushes when they reach their minimum acceptable length.

Q: How long do slip rings and carbon brushes typically last?

A: The lifespan of slip rings and carbon brushes varies widely depending on the application, material quality, environmental conditions, and maintenance practices. In general, carbon brushes may require replacement after thousands of hours of operation, but some high-quality slip ring assemblies can last the lifetime of the equipment in which they are installed.

Q: What happens if carbon brushes wear down?

A: Worn-down carbon brushes can lead to poor electrical contact, sparking, and irregular power transmission. This can cause damage to the slip rings, reduce the performance of the equipment, and potentially lead to system failure. Regular inspection and timely replacement of brushes are essential to prevent these issues.

Q: Can slip rings and carbon brushes be used in harsh environments?

A: Yes, there are slip ring and carbon brush assemblies designed to withstand harsh environments, including those with high levels of moisture, dust, or extreme temperatures. These specialized components are constructed with durable materials and protective enclosures to ensure reliable operation under challenging conditions.

Q: Are there environmentally friendly options for slip rings and carbon brushes?

A: Manufacturers are increasingly adopting environmentally responsible practices by using materials that are less harmful to the environment, improving manufacturing processes to reduce waste, and designing products that last longer to minimize replacement frequency. Some slip rings are also recyclable, contributing to a lower environmental impact.

Q: What are the alternatives to slip rings and carbon brushes if I want to eliminate wear and maintenance?

A: Contactless alternatives to traditional slip ring and carbon brush assemblies include inductive couplings, capacitive couplings, and optical rotary joints. These technologies enable power and data transmission without physical contact, thus eliminating wear and significantly reducing maintenance requirements. However, they may have limitations in power handling or may not be suitable for certain applications.

See What We Can Do