The way we gather, analyze, and interpret data shapes the backbone of numerous operations, notably in fields like surveying, construction, and civil engineering. Within these operations, total station detectors have revolutionized our approach, providing precise data while optimizing workflow efficiency. Serving as a nexus between mechanical components and data systems, slip rings have an integral and often underrated role in total station detectors. From facilitating constant power supply to allowing smooth, uninterrupted signal transmission, their application significantly affects the overall performance and applicability of the devices.

Understanding the applications of slip rings in these detectors isn’t merely technical jargon reserved for engineers and manufacturers. It’s of primary importance for anyone using total station detectors, regardless of their role or industry. With a closer look at how slip rings function within these devices, users can optimize their operations, minimize errors, and capitalize on their total station’s full feature set. Further, as stakeholders in the broader landscape—from decision-makers considering an investment in total stations to teams responsible for maintenance and troubleshooting—this understanding forms a key foundation.

Therefore, the discussion on the application of slip rings application in total station detectors is not simply an exploration of the mechanism; it’s about unlocking potential, streamlining operations, and making the most of technological investments.

Role of Slip Rings Application in Total Station Detectors

The heart of many electromechanical devices—like wind turbines, CT scanners, and total station detectors—beats due to an often unseen component: the slip ring. Acting as a bridge between stationary and rotating parts, slip rings enable the transfer of electrical signals and power amidst constant rotational movement. In the case of a total station detector, this continuous flow of data and power is not just an advantage—it’s essential for its operations.

For total station detectors, constant power and signal transition underscores every measurement, every data point, and every conclusion drawn. Slip rings play an instrumental role in this process. As the total station rotates to map its surroundings, the slip ring ensures a seamless transfer of power to different parts of the device and maintains continuous signal transmission from various sensors to the central processor.

At first glance, the 360-degree rotation might seem like a simple operation, but in reality, it’s a critical operation that facilitates essential data acquisition. The total station detector’s ability to rotate fully allows it to map a comprehensive and accurate 360-degree survey of its environment. But this wouldn’t be possible without the slip ring. As the total station detector rotates, the slip ring maintains unbroken electrical connections, ensuring data from each degree of rotation is preserved and processed accurately.

In essence, the slip ring is the silent force that amplifies the total station detector’s capabilities. Every degree of rotation, and every data point acquired, owes its success to the flawless operation of the slip ring. Therefore, understanding the role of slip rings in total station detectors provides a new lens to appreciate these instruments’ intricacy and inherent genius.

Benefits of Using Slip Rings Application in Total Station Detectors

When it comes to total station detectors, slip rings aren’t just a feature—they become one of the defining factors influencing the device’s performance, lifespan, and most importantly, the reliability of the data it produces. Anyone vested in the process of accurate data collection and measurement understands that the integrity of this data is paramount. Slip rings are instrumental in enhancing this integrity.

A crucial link in the chain of data collection, slip rings ensure an unbroken flow of data from rotating sensors to stationary components. This seamless transmission means that every data point collected by the rotating sensor is accurately represented in the end output, making sure the total station yields accurate results. Think of slip rings as a trustworthy translator, precisely communicating every bit of data without any loss in translation.

What sets slip rings in total station detectors apart is their contribution to reliability. With their ability to maintain constant power and signal transition, these devices can operate reliably, regardless of their rotation frequency or duration. This reliability is a game-changer, particularly in extensive surveying or construction projects where continuous operation becomes a necessity.

The benefits of using slip rings don’t stop at improving data accuracy and operational reliability. They also play an influential role in enhancing the device’s lifespan. How? As they facilitate uniform rotation without straining the device’s mechanical components, the overall wear and tear of the total station detector is significantly reduced. This aspect, combined with their ability to maintain electrical connections even under extreme environmental conditions, means the total station detectors equipped with slip rings can offer users a longer equipment service life.

In a broader context, the inclusion of slip rings in total station detectors becomes a matter of operating sustainability. By ensuring accurate data output, reliable performance, and enhanced lifespan, slip rings microscopically contribute to larger efficiencies in surveying, construction, and civil engineering contexts.

Types of Slip Rings Application in Total Station Detectors

Total station detectors, with their complex rotation and data transmission requirements, call for specific types of slip rings that can handle these demands effectively. Among the numerous slip ring varieties available today, capsule and pancake slip rings emerge as the frontrunners for total station detector applications.

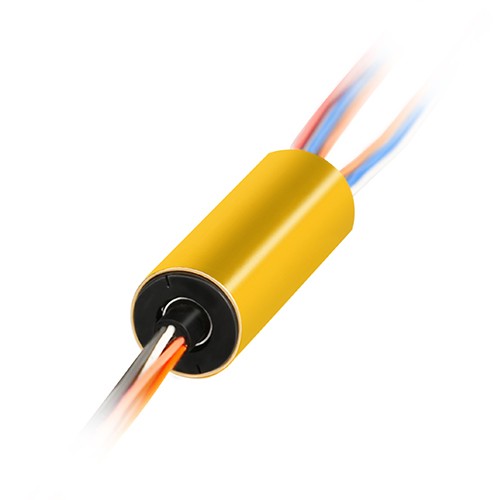

Capsule slip rings, known for their compact form factor, are a common choice for total station detectors. Enclosed within a compact body, these slip rings present a range of circuits—from a bare few to several dozen—making them an adaptable choice for varying station needs. Their small size doesn’t restrict their performance, as they can efficiently transmit power and multiple types of signals. With their straightforward integration, capsule slip rings enable the central module to rotate freely without hindrance, enhancing the device’s mobility and performance.

Pancake slip rings, on the other hand, come in a flat, disc-like shape, hence their name. Despite their distinctly low profile, pancake slip rings are designed to offer an impressive number of circuits. This characteristic makes them incredibly suitable for total station detectors requiring a large data transmission capacity without compromising on the compactness of the design.

While these slip ring types differ in their form factors, they both uphold the key requirements for total station detectors: a high capacity for signal and power transmission and a form that enables smooth, uninterrupted rotation. The choice between them often comes down to the specific demands of the total station detector—whether it prioritizes a slim form factor, as with pancake slip rings, or prefers the versatile and compact nature of capsule slip rings.

By understanding the unique characteristics offered by capsule and pancake slip rings, users can enhance the data collection process and overall operational efficiency of total station detectors, placing them in a stronger, more reliable position to tackle complex projects.

Considerations when Selecting Slip Rings Application in Total Station Detectors

Slip rings, as fundamental as they may be to total station detectors, are not a one-size-fits-all component. This small yet crucial component needs as much careful selection as any other part of the device, because the performance, lifespan, and ultimately the success of a project could depend on it. Here, we delve into the key factors that must guide this selection process.

First and foremost is the size of the slip ring. The compactness of slip rings in total station detectors is crucial, not just for saving space, but more importantly, for allowing unrestricted rotation. Care must be taken to ensure that the slip ring selected finetunes closely with the design requirement of the detector.

Electrical noise—the interference or disruptions in electrical signal transmission—plays a significant role in selecting slip rings. An ideal slip ring should minimize electrical noise, ensuring data integrity and accurate interpretation. In context, electrical noise can disrupt the proper functioning of the total station detector, necessitating slip rings that offer low electrical noise.

The rotational speed at which the slip ring can operate also comes into consideration. In a total station detector, high rotational speed might be required to quickly survey the environment. The chosen slip ring must accommodate this need without compromising the power and signal transmission.

The number of circuits required in the slip ring is another deciding factor. The more sensors and components a total station detector has, the more circuits you’ll need for your slip ring to transmit that data efficiently. Consequently, the choice of slip ring should align with the device’s complexity and data transmission needs.

Lastly, resistance to environmental factors is key. Total station detectors are often used in varying weather conditions. Thus, the slip rings need to resist factors like dust and humidity, which can impact the electrical connections and overall device performance.

In conclusion, the careful selection of slip rings keeps the integrity of total station detectors intact. The best choice takes into account the operational needs, the environmental variables, and the device’s design specifics—a missing piece in this intricate puzzle could steer a total station detector away from its optimum performance. The right slip ring not only enhances the efficacy of total station detectors but also contributes to their trouble-free, longevity.

Case Studies: Effective Use of Slip Rings Application in Total Station Detectors

While understanding the technical aspects of slip rings is essential, observing them in real-world applications can provide a more rounded perspective. These actual instances of use validate the transformative effect of slip rings on total station detectors. Let’s consider two such case studies:

Major Surveying Project in Tokyo, Japan

In an extensive surveying project for a new railway line in Tokyo, Japan, total station detectors played a crucial role in acquiring precise measurements. The challenging terrain and dense urban surroundings required continuous operation and high accuracy—demands met by the slip rings in the detectors. The specialty capsule slip rings in these stations allowed seamless rotation and data transmission, which were instrumental in mitigating the complexities of land surveying in such a densely populated territory. The project was completed successfully within the planned timeframe, and the data collected was of high accuracy—a testament to the effective functionality of slip rings.

Construction Project in New York City, USA

In one of the new skyscraper projects in New York City, USA, total station detectors were employed for an array of measurements, including calculating distances, angles, and elevations. Given the significant height of the building and large scope of work, the pancake slip ring-based total station detectors were chosen for their compactness and high data transmission capacity. These slip rings simplified the arduous task of measurement at such height and breadth, ensuring continuous data collection and electric power supply, thereby leading to efficient construction planning and execution. This enabled the protection of the project timeline and budget, showcasing the high-performance contribution of the slip rings.

In both cases, the slip rings showcased their worth, contributing to the success of complex projects where precision, efficiency, and reliability were non-negotiable. The results speak for themselves, illustrating the indispensable role of slip rings in total station detectors’ operation and, in turn, in the larger frame of surveying and construction projects.

Maintenance and Troubleshooting of Slip Rings Application in Total Station Detectors

The performance and longevity of slip rings in total station detectors can be ensured with regular maintenance and proficient troubleshooting. Here are some practical tips and guidelines to achieve these goals:

Regular Cleaning

Slip rings operate in varied environments that could expose them to dirt and dust. Regular cleaning helps prevent dust accumulation, which can disrupt electrical connections and subsequently affect the performance of the total station detector. Use a soft brush or compressed air canister to gently clean the slip rings without causing any physical damage.

Lubrication

Periodically lubricating the slip rings can reduce wear and tear, prolonging their life. It’s important to use the right lubricant—one that doesn’t inhibit electrical conductivity. Ensure that the lubrication process is done with the station powered off to prevent any electric shock or short-circuiting.

Regular Inspections

Regularly inspect the slip rings for any signs of physical damage or wear. Check for any changes in the rotation of the detector’s module—if it isn’t as smooth as it normally is, the slip ring may be worn out and may require replacement.

Troubleshooting Noise Issues

If you notice an increase in the electrical noise, it might be due to dirt accumulation or a worn-out contact surface. Cleaning can resolve the first issue, but if the contact surface is worn beyond repair, you may have to replace the slip ring.

Dealing with Environmental Resistance Issues

Occasionally, slip rings may face problems operating in extreme weather conditions. If you notice a decrease in performance in such conditions, inspect the ring for any signs of physical degradation or corrosion. Consider using slip rings that are specifically designed to resist such environments.

By following these maintenance and troubleshooting tips, you can enhance the performance and extend the lifespan of your slip rings, ensuring that your total station detector serves you well in the long run. Keep in mind that the exact maintenance and troubleshooting details can vary based on the specific model and make of your slip ring, so always refer to the manufacturer’s guide alongside these general guidelines.

Conclusion

Slip rings play a fundamental role in enhancing the performance and reliability of total station detectors. By ensuring power and signal continuity, facilitating device rotation, and improving device lifespan, slip rings prove an indispensable component in total station detector design. Careful selection, proper maintenance, and regular troubleshooting will ensure a total station detector performance remains accurate and reliable for the long term.

FAQs About Slip Rings Application in Total Station Detectors

Slip rings in total station detectors indeed raise some questions due to their critical role in such devices. In this section, we address some of the most common queries and concerns that users may bring up.

Q: How Long Do Slip Rings Last in Total Station Detectors?

A: The lifespan of slip rings in total station detectors varies, but with proper usage and maintenance, they can effectively function for several years. Factors such as environmental conditions, usage frequency, and the quality of the slip ring itself can influence this lifespan.

Q: Can I Use Any Type of Slip Ring for My Total Station Detector?

A: Not all slip rings are suited for total station detector applications. You should consider factors such as the size, the electrical noise, rotational speed, the number of circuits, and environmental resistance when selecting slip rings for total station detectors.

Q: How Can I Maintain the Slip Rings in My Total Station Detector?

A: Slow and minimal wear of the contact materials over time is natural. Regular dusting can prevent the accumulation of foreign matter, which can affect performance over time. For pancake-type slip rings especially, cleaning the individual rings and brush blocks for debris can help maintain their performance.

Q: Does the Number of Circuits Influence the Performance of My Total Station Detector?

A: Yes, the number of circuits in a slip ring does influence the performance of the total station detector. The more circuits a slip ring possesses, the greater its data transmission capacity. Therefore, if your total station detector necessitates high-volume data transmission, you should go for a slip ring with more circuits.

Q: How Do Slip Rings Enhance the Performance of Total Station Detectors?

A: Slip rings enhance total station detector performance by enabling the seamless rotation of the central module, therefore reducing mechanical strain. They also facilitate an uninterrupted flow of data and power from rotating sensors to stationary components, thereby ensuring accurate measurements, reliable long-term operation, and extended equipment life.

Q: Can Slip Rings Operate under Extreme Weather Conditions?

A: Yes, slip rings can operate under diverse environmental conditions including extreme cold, heat, and dust. However, their performance can be influenced by these factors; the more resistant a slip ring is to these influences, the more consistently it will perform.

See What We Can Do