In the world of engineering and innovation, finding efficient solutions for transmitting power and data in compact rotating systems has always been a challenge. However, a groundbreaking invention has emerged to address this very issue: the small pancake slip ring. This remarkable device has captured the attention of industries and DIY enthusiasts alike, offering a compact and reliable solution for seamless power and data transmission in space-constrained applications. In this article, we delve into the world of small pancake slip rings, exploring their features, applications, and the transformative impact they are having on various sectors.

Introducing the Small Pancake Slip Ring

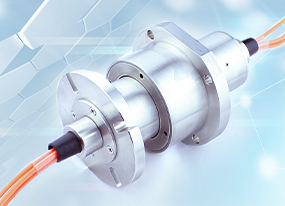

The small pancake slip ring is a technological marvel that allows for continuous electrical connectivity between rotating and stationary components in tight spaces. It is an innovation that has revolutionized the way power and data are transmitted in applications where size and weight are critical factors. Unlike traditional slip rings, which can be bulky and cumbersome, the small pancake slip ring offers a compact and efficient solution without compromising performance.

Compact Design, Big Potential

The small pancake slip ring derives its name from its flat, disc-like shape, resembling a pancake. This design allows for a slim profile, making it ideal for applications with limited space. The compact nature of these slip rings does not compromise their performance capabilities. They can handle a wide range of electrical signals, including power, analog, and digital signals, as well as high-frequency data transmission, all while maintaining electrical integrity during rotation.

Applications in Various Industries

The small pancake slip ring has found applications in diverse industries, catering to the unique needs of compact rotating systems. Let’s explore some key sectors where these slip rings are making a significant impact:

Robotics and Automation: Compact robots and automated systems require reliable power and data transmission between rotating joints or components. Small pancake slip rings enable seamless connectivity, facilitating smooth motion and precise control in applications such as robotic arms, automated assembly lines, and inspection systems. The compact design allows for greater flexibility in robot design, enabling intricate and space-saving configurations.

Medical Devices and Equipment: In the medical field, space is often at a premium in devices such as surgical robots, endoscopes, and medical imaging equipment. Small pancake slip rings play a crucial role in transmitting power and signals to rotating components within these compact medical devices. They enable precise movement, enhanced control, and uninterrupted data transmission, contributing to advancements in minimally invasive surgeries and medical diagnostics.

Aerospace and Defense: The aerospace and defense sectors require compact and reliable power and data transmission solutions for various applications, including surveillance systems, radar installations, and satellite tracking. Small pancake slip rings are invaluable in these scenarios, enabling uninterrupted communication and power supply to rotating elements while withstanding challenging environmental conditions.

Industrial Machinery: Compact rotating systems in industrial machinery, such as indexing tables, packaging equipment, and automated test rigs, rely on small pancake slip rings for seamless power and signal transmission. These slip rings ensure uninterrupted operation and precise control, optimizing the efficiency and performance of industrial processes.

Pushing the Boundaries of Miniaturization

The development of small pancake slip rings is a testament to the relentless pursuit of miniaturization in the field of engineering. As technology advances, slip ring manufacturers and researchers continue to push the boundaries of size reduction while maintaining performance standards. New materials, advanced manufacturing techniques, and precise engineering have contributed to the creation of compact slip rings with exceptional capabilities.

Overcoming Challenges of Miniaturization

The miniaturization of slip rings poses several challenges that engineers and designers must address. Some of the key considerations include:

Heat Dissipation: The compact size of small pancake slip rings limits the surface area available for heat dissipation. Efficient thermal management techniques, such as heat sinks or ventilation, are crucial to ensure optimal slip ring performance and prevent overheating.

Signal Integrity: Maintaining signal integrity becomes more challenging as the size of the slip ring decreases. Designers must employ effective shielding techniques, high-quality connectors, and proper grounding to minimize signal loss, noise, and interference.

Mechanical Stability: The compact design of small pancake slip rings requires meticulous attention to mechanical stability. Rigorous testing and optimization of materials, bearing systems, and contact mechanisms are essential to ensure reliable operation, even under harsh conditions.

Future Prospects and Advancements

The small pancake slip ring market is poised for significant growth as industries increasingly demand compact and efficient power and data transmission solutions. Advancements in materials, miniaturization techniques, and automation processes will further enhance the capabilities of these slip rings. Additionally, the integration of advanced technologies such as wireless power transmission and contactless data transfer may redefine the landscape of small slip ring applications.

The small pancake slip ring has emerged as a transformative solution, revolutionizing power and data transmission in compact rotating systems across various industries. With their compact design and exceptional performance, these slip rings are unlocking new possibilities for robotics, medical devices, aerospace, and industrial machinery. As technology continues to advance, we can expect further innovations and advancements in small pancake slip ring technology, pushing the boundaries of miniaturization and paving the way for more efficient, reliable, and versatile rotating systems in the future.

See What We Can Do