Slip ring motors, also known as wound rotor motors, are specialized electric motors that offer unique advantages, including high starting torque and adjustable speed control. However, due to their distinctive design and operating characteristics, starting a slip ring motor requires specific considerations to ensure safe and efficient motor startup. This article aims to provide an overview of slip ring motors, explain different starting methods, and highlight important precautions and best practices to follow during motor startup.

Overview of Slip Ring Motors

Definition and Construction

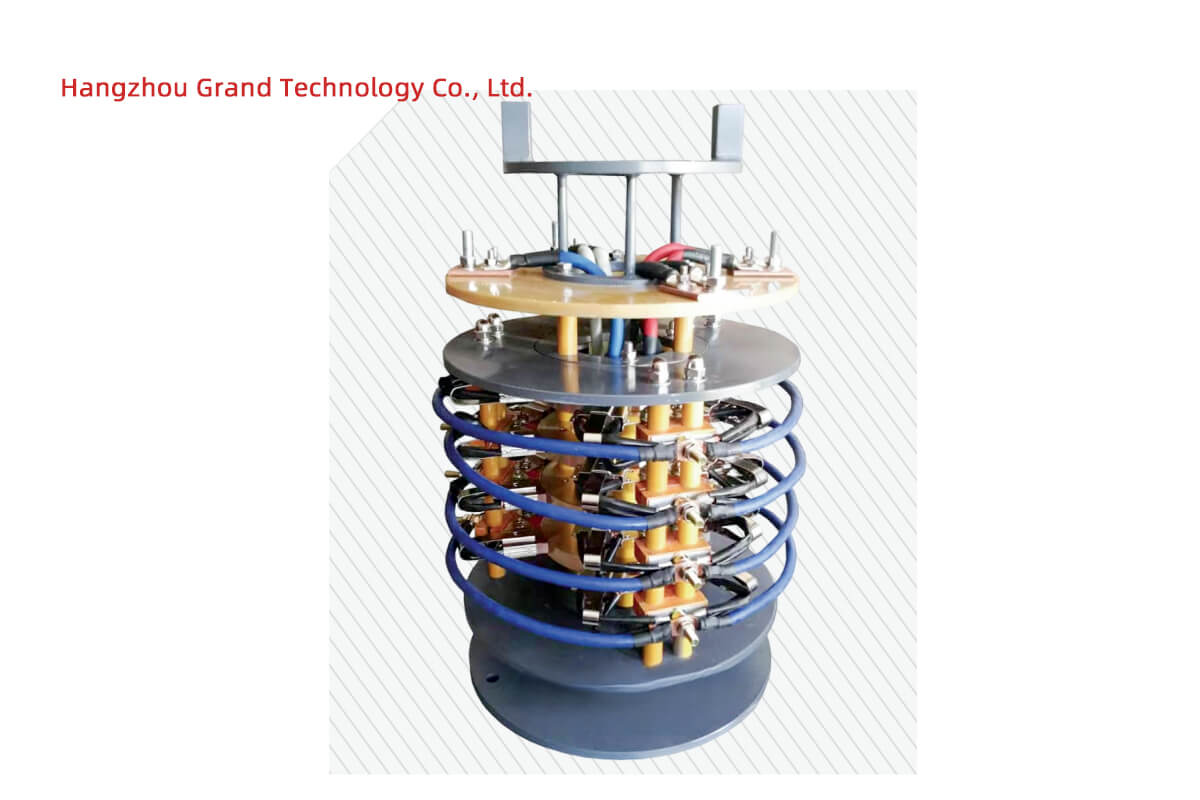

To understand the starting methods of slip ring motors, it is essential to grasp their basic components. Slip ring motors consist of two main parts: the stator and the rotor. The stator has fixed windings that generate a rotating magnetic field when connected to a power supply. The rotor, on the other hand, has windings that are connected to external electrical circuits through slip rings and brushes. These slip rings allow electrical contact between the stationary and rotating parts of the motor, enabling the flow of electrical signals to the rotor windings.

Key Characteristics

Slip ring motors are renowned for their high starting torque capabilities. During startup, they can handle heavy loads and provide a powerful torque to initiate motion smoothly. Additionally, these motors offer adjustable speed control, allowing for precise regulation of the motor’s speed according to the specific requirements of the application. This versatility makes slip ring motors suitable for various industrial scenarios where starting torque and speed control are crucial.

Starting Methods for Slip Ring Motors

Direct-On-Line (DOL) Starting

The Direct-On-Line (DOL) starting method is the simplest and most straightforward way to start a slip ring motor. In this method, the motor is directly connected to the power supply, allowing full voltage to reach both the stator and the rotor windings through the slip rings. As a result, the motor receives full power from the beginning, providing a high starting torque. However, one significant drawback of DOL starting is the high inrush current that occurs during the startup process. This can lead to mechanical stresses on the motor and may cause disturbances in the power supply network.

Reduced Voltage Starting

Reduced voltage starting methods aim to limit the voltage applied to the motor during startup. This helps to reduce the inrush currents and minimize mechanical stresses, making it a more controlled and safer approach. There are several common reduced voltage starting methods:

– Autotransformer Starting: In autotransformer starting, the motor is connected to an autotransformer that reduces the voltage supplied to the motor during startup. As the motor accelerates, the voltage is gradually increased, allowing for a smooth and controlled startup with reduced inrush currents.

– Star-Delta Starting: In star-delta starting, the motor is initially connected in a star configuration, which reduces the voltage across the windings. Once the motor reaches a specific speed, it is switched to a delta configuration, enabling full voltage operation.

– Resistor Starting: Resistor starting involves inserting resistors in the rotor circuit during startup to limit the current and torque. As the motor accelerates, the resistors are gradually removed, allowing for a smooth transition to full voltage operation.

Precautions and Best Practices for Starting Slip Ring Motors

Pre-Startup Checks

Before starting a slip ring motor, it is crucial to conduct pre-startup checks. Ensure that all control and protection devices, such as contractors, overcurrent relays, and thermal overload relays, are in proper working condition. Verify that the mechanical load is appropriately disconnected from the motor, and the motor is in a suitable operating condition.

Motor Protection

Implementing appropriate motor protection measures is essential to ensure the motor’s safe operation during startup and regular operation. Thermal overload protection, overcurrent protection, and voltage monitoring devices should be installed to prevent damage to the motor due to excessive temperature or electrical faults.

Monitoring and Adjustments

During motor startup, closely monitor the motor’s behavior, including parameters such as current draw, voltage fluctuations, and any abnormal signals. Adjust the starting method or parameters as necessary to optimize motor performance and protect it from excessive stresses.

Training and Safety

It is essential that personnel involved in starting slip ring motors are adequately trained on the specific procedures and safety precautions. Emphasize the importance of following manufacturer guidelines and safety regulations to mitigate risks during motor startup.

Starting a slip ring motor requires a thorough understanding of the different starting methods, precautions, and best practices to ensure safe and efficient motor operation. By choosing the appropriate starting method and implementing necessary safety measures, slip ring motors can be effectively started, leading to reliable and optimal performance in various industrial applications. Careful consideration and adherence to best practices will enable engineers and operators to harness the high starting torque and adjustable speed control offered by slip ring motors, making them valuable assets in specialized industries where heavy loads and precise speed regulation are vital.

See What We Can Do