Small slip ring connectors, despite their rather unassuming namesake and size, embody a transformative wonder of modern engineering. At its core, a small slip ring connector can be understood as a specialized device that facilitates unrestricted, continuous rotation while transmitting power and electrical signals from a stationary component to a rotating one within a system. This is no trivial task. Overcoming friction, withstanding wear and tear, and maintaining efficient conductivity — these are quite some feats to accomplish, especially considering their compact size.

The purpose of small slip ring connectors extends far beyond simple power or signal transmission. They are essentially the unsung heroes that form the crucial link in many of our everyday gadgets and industrial machinery. Anything that moves, or rather, spins uses them. From digital cameras capturing precious moments, and electric cars navigating city streets, to wind turbines, harnessing the power of nature – they all depend on slip ring connectors to ensure an uninterrupted flow of power or electrical signals. It is this convergence of form and function, of intricate design and utility, that makes small slip ring connectors a fascinating topic of discussion.

As we delve deeper into understanding these masterpieces of mechatronics, one begins to appreciate their intricate design, diverse applications, and the nuances involved in their usage, maintenance, and selection. This knowledge is not merely academic; it empowers consumers, engineers, and enthusiasts to make informed choices and optimally leverage the myriad capabilities of small slip ring connectors.

https://www.grandslipring.com/surveillance-video-small-slip-ring-connector-enhances-security/https://www.grandslipring.com/a-comprehensive-guide-to-flat-disc-electrical-slip-rings/https://www.grandslipring.com/rotating-slip-ring-connectors-enhancing-surveillance-video/

Design & Construction of Small Slip Ring Connectors

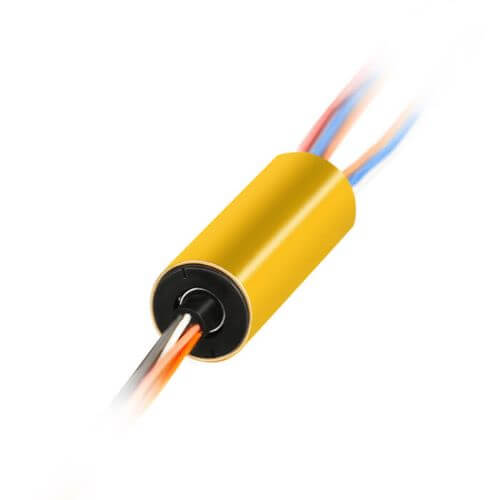

Understanding the design and construction of small slip ring connectors helps illuminate the intricate balance of mechanical precision, materials science, and innovative assembly techniques that go into forging these compact powerhouses. At the heart of these connectors lies the basic elements: a conductive ring and several stationary brushes. The brushes remain in constant contact with the ring, which rotates. As electricity or signals pass from the stationary component (through the brushes) to the rotating part (through the conductive ring), the fundamental process of power or signal transfer is accomplished.

However, this basic operation is steeped in a wealth of engineering nuances. To initiate, material selection plays a pivotal role. The conductive ring involves conductive material capable of withstanding constant rotation while maintaining adequate conductivity. At the same time, the brushes need to be made of a material that can sustain constant mechanical contact with the ring without causing substantial wear and tear. This delicate balance is achieved through the use of advanced materials, often metals or advanced alloys, which offer the ideal mix of durability and conductivity.

Next, comes the assembly. Small slip ring connectors are often assembled in a layered manner, with the rotating conductive ring surrounded by the stationary brushes. This layered setup allows efficient spatial usage, which is critical for maintaining the small size. Furthermore, advances in micro-manufacturing techniques have made it possible to achieve extremely high precision in assembly, necessary for ensuring reliable performance.

The compactness of these connectors isn’t merely a novelty. Their small size is driven by the need to fit into various devices, from compact consumer electronics to size-constrained industrial machinery. This miniaturization has been made possible due to advancements in materials and assembly techniques that not only allow for downsizing the design but do so without compromising the connector’s performance or durability.

Therefore, through careful design considerations, guided by a precise understanding of their role and operating conditions, small slip ring connectors reflect a marvel of modern engineering. Their compact design, robust performance, and understated elegance are a testament to the ingenuity that has gone into their creation.

Small Slip Ring Connectors Types and Variations

Small slip ring connectors, much like any field of engineering design, come in numerous types and variations, each designed to address a specific requirement or facilitate a unique operation. The broad spectrum of these connectors not only reflects the vast array of applications they can cater to but also the technological advancements that have spurred the development of specialized models.

One widely recognized type is the capsule slip ring, known for its compact form and high performance. They are typically used where a small, streamlined package is desired. Small size doesn’t compromise the performance, however; these connectors are often capable of high-speed data transmission, making them ideal for applications in high-speed communication devices, CCTV systems, or in robotics where space is at a premium.

Another variant is the miniature slip ring, famous for its tininess and lightness. They are smaller than the capsule type and are often built to serve in specific applications, such as medical devices, where size constraints are significant.

Meanwhile, through-bore slip rings add another dimension to the versatility of slip ring connectors by featuring a central hole. This hole or “bore” can accommodate a shaft or other medium, allowing extra functionality in the system. They are often found in wind turbines or radar systems where a central rotating shaft is part of the system’s design.

Pancake slip rings are yet another different kind. Their distinguishing feature is the disk-like shape, which is ideally suited for applications with height restrictions but less concern about the system’s radial size, like in some printing and textile machines.

The adaptation of small slip ring connectors across varied fields speaks volumes about their flexibility and versatility in design. Each model, with its unique features, caters to different operational needs, confirming how these compact marvels can wear many hats, addressing needs as diverse as transmitting high-speed data signals to allowing unrestricted rotation within a confined space. Such diverse embodiment of function in varied forms truly underscores the genius behind the design and application of small slip ring connectors.

Applications of Small Slip Ring Connectors

The multifaceted nature of small slip ring connectors is perhaps most vividly brought to light when looking at their diverse applications across numerous devices and sectors. These small yet critical components find their way into an astonishing range of systems, ensuring consistent power and signal transfer, preserving the tempo of life as we know it.

One of the most important applications of small slip ring connectors can be found in wind turbines. Here, they bridge the gap between the static tower and the rotating blades, transmitting power produced by the turbine’s generator down the tower for distribution. Their seamless operation ensures the energy harnessed from the wind does not get interrupted due to rotational movements.

In the world of medicine, their footprint is equally significant. In medical imaging devices such as CT scanners, small slip ring connectors ensure that the gantry’s continuous rotation does not impede the electrical signals coming from the detectors. This ensures high-quality imaging, all the while avoiding the impracticality of tangled wires.

Further, they also find a prominent place in telecommunications. Broadcasting and communication systems rely on slip ring connectors to enable satellite dishes’ rotation while maintaining unhindered signal transmission from other electronics at the base.

On a smaller scale, consumer electronics like portable digital cameras also utilize the handy work of these connectors. The continuous power supply to the rotary components in the zoom or optical image stabilization is made possible by small slip ring connectors.

In military applications, the connectors are of paramount importance in radar systems. The antenna needs to rotate continuously for surveillance, and the uninterrupted flow of signals is ensured by these slip ring connectors.

Other sectors, such as robotics, avionics, and manufacturing, also heavily rely on the seamless service of small slip ring connectors.

Thus, these connectors play an instrumental role in maintaining the unimpeded operation of systems across various domains. Their ability to support a smooth rotation while ensuring an uninterrupted flow of electric signals or power is what powers these systems, from photovoltaics and wind turbines, through medical technology, to robotics and consumer electronics. Small slip ring connectors, in essence, contribute significantly to the rhythmic dance of progress in the modern world.

Small Slip Ring Connectors Installation and Usage

Correct installation and usage of small slip ring connectors can significantly impact their performance and longevity. Though these connectors are robustly designed, paying attention to certain aspects during their installation and use can avoid potential complications and ensure smooth operations.

Installation starts with careful selection of the connector type and model suitable for the application. This goes hand in hand with an appreciation of the system’s requirements, including the physical space available for the connector and the nature of the signals or power it needs to transfer.

Once the appropriate connector is chosen, the actual installation begins. The stationary part of the connector, where the brushes reside, is typically mounted onto a non-moving portion of the system. Oppositely, the conductive ring is attached to the rotating component of the device. Care should be taken to ensure a firm and secure connection on both ends, as inadequate coupling can lead to instability and inefficient operation.

Wiring is another crucial aspect of installation. Wires from the stationary component that carry the signals or power should be correctly connected to the brushes using the recommended connectors. Similarly, conductive rings should be adequately connected to the rotating part’s respective wires. Miswiring not only threatens performance but can also lead to potential electrical hazards.

Once installed, regular inspection and cleaning are good usage habits. Dust or debris can accumulate over time and pose an undue detriment to the connector’s operation.

Avoiding common mistakes such as overloading the connector beyond its rated capacity, ignoring periodic maintenance, or bypassing proper grounding procedures will surely enhance the device’s operational life and performance.

In essence, a well-installed and maintained small slip ring connector is not only an asset to the system it’s part of but also a testimony to good engineering practices. So, while the connectors themselves might be mechanically small, the attention to detail and care during their installation and usage should certainly not follow suit.

Small Slip Ring Connectors Buying Considerations

Selecting the right small slip ring connector can be a critical factor in the smooth operation of a device or system. Therefore, keen consideration should be given to several key aspects when contemplating a purchase.

Compatibility: The first consideration should be aligning the connector with the system’s requirements. System parameters like current, voltage, rotational speed, and the number of circuits guide the suitability of a slip ring connector. Similarly, the space available for installation and whether the required installation is static, rotary, or a combination of both also play into the selection process. The user manual or system specifications often include these details. Adopting a connector that matches these specifications ensures compatibility and optimum performance.

Quality: High-quality connectors typically boast some key characteristics, including smooth operation without perceptible noise or vibration, robust build that can withstand constant rotation and friction, and a certain lifespan during which they can operate without significant degradation. Durable materials like advanced alloys, proprietary coating techniques on contact surfaces, and excellent craftsmanship signify high-quality connectors. Be sure to inspect these attributes or ask for detailed specifications from the manufacturer.

Price: Though prices can vary based on the slip ring’s specifications and the quality of materials used, it’s crucial to remember the vital role these connectors play. High-quality connectors may carry a higher price tag but offer longevity, reliability, and peace of mind––all of which often outweigh the initial cost. Nonetheless, it’s always advisable to compare prices from different manufacturers for connectors with similar specifications.

Brand Reputation: Choosing a connector from a reputable brand can give users added assurance about the product’s quality and reliability. Reputable brands often have a track record of delivering high-performance products and superior customer support. Reviews, testimonials, and word-of-mouth recommendations can offer insights into the reputation of a brand.

In conclusion, careful examination of compatibility, quality, price, and brand reputation can help users navigate the purchasing process more effectively, ensuring that they procure a small slip ring connector that does justice to their system’s operational needs and expectations.

Small Slip Ring Connectors Maintenance & Troubleshooting

Maintaining a small slip ring connector efficiently and dealing with potential problems requires conscious effort and an understanding of the device’s operational nuances. However, a well-maintained connector can have greatly extended operational life and reliability.

Maintenance: For optimal functionality and longevity, slip ring connectors require regular inspection and maintenance. Periodically checking the connector for dust and debris and cleaning it gently can prevent damage to accumulation.

Ensure the connector is not exposed to an environment beyond its capacity, such as extreme temperatures or moisture levels. Such conditions could compromise the connector’s operation and life span.

In the case of the connectors equipped with replaceable brush contacts, check for wear routinely and replace them as needed. This proactive measure can prevent potential power or signal disruptions.

Moreover, periodic confirmation of secure attachment and proper wiring can prevent unnecessary wear and tear or misoperation, which might go unnoticed until they cause serious problems.

Troubleshooting: Despite diligent maintenance, there might be instances when the slip ring connector presents issues. One of the first steps in troubleshooting is verifying that the problem does indeed stem from the connector.

A common issue could be an interruption in power or signal, which might be due to worn brushes, a disrupted wire connection, or accumulated debris. Assessing each possibility methodically can lead to the identification and rectification of the problem.

Noise or vibration during operation may be indicative of misalignment or loose connections. A thorough review of the installation and tightened connections can often alleviate such issues.

In case of complex issues or situations when the trouble persists, it’s best to consult a professional or reach out to the manufacturer’s technical support team.

In essence, understanding that maintenance is a proactive measure and not a reactive solution, coupled with systematic troubleshooting, can dramatically enhance the small slip ring connector’s performance and longevity, and in turn, that of the system it serves.

Conclusion

Small slip ring connectors are truly marvels of electrical and mechanical engineering. Their compact size houses robust performance and endless application potential. Armed with knowledge about these little powerhouses, you can select, install, and maintain them effectively, giving your systems an undeterred, long-lasting rotation/transmission power.

FAQs about Small Slip Ring Connector

Below are some commonly asked questions about small slip ring connectors that can provide users with further clarity about their operation, characteristics, and benefits.

Q: What is a small slip ring connector?

A: Small slip ring connectors are devices used to transmit power and electrical signals from a stationary part of a device to its rotating part without hindrance, ensuring continuous, smooth operation.

Q: How does a small slip ring connector work?

A: A small slip ring connector primarily consists of rotating conductive rings and stationary brushes. As the rings rotate with the movement in the device, the brushes maintain contact, allowing the flow of power or signals from the stationary component to the moving part of the system.

Q: Where are small slip ring connectors used?

A: Small slip ring connectors find a wide variety of applications, including wind turbines, medical imaging devices, radar systems, consumer electronics, and more. They are fundamental to systems or devices where continuous rotation along with electrical continuity is required.

Q: How long does a small slip ring connector last?

A: The lifespan of a small slip ring connector depends on its operational conditions and maintenance. These connectors can often last for millions of rotations with regular inspection, cleaning, and appropriate usage.

Q: How do I choose the right small slip ring connector?

A: Choosing the right slip ring connector involves considering several factors such as compatibility with the system requirements, quality, price, and brand reputation. Detailed specifications of the system and the connector, as well as understanding the operational environment, play significant roles in making the right selection.

Q: How to maintain and troubleshoot a small slip ring connector?

A: Regular inspection and cleaning, protection from harsh environments, and careful usage can ensure the longevity of a small slip ring connector. If an issue arises, methodical troubleshooting starting with confirming the source of the problem, and then assessing possible causes and remedies, can often fix the problem. In complex cases, consulting professionals or manufacturer’s support is recommended.

See What We Can Do