This article provides a detailed guide on bore slip rings, covering everything from basic understanding, selection criteria, installation, maintenance practices, and cost considerations, to their wide-ranging applications and future advancements. It’s designed to demystify through bore slip rings for a varied audience, from industry professionals to technology enthusiasts.

Introduction to Through Bore Slip Rings

The evolution of electromechanical systems has necessitated components that can ensure seamless functionality even in the most dynamic and complex mechanical assemblies. Among these pivotal components are bored slip rings, devices ingeniously designed to bridge the divide between stationary structures and rotating platforms. Through bore slip rings are specialized electromechanical gadgets that facilitate the continuous transfer of power and signals across rotating interfaces, all while accommodating a central pass-through, or “bore,” which can be used to route various mechanical or electrical elements through the center of the mechanism.

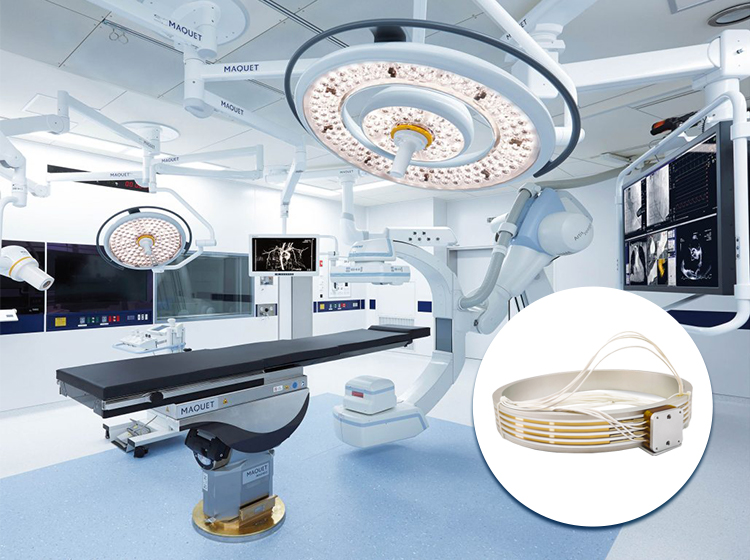

This unique feature makes them indispensable in numerous applications where uninterrupted rotational movement and the concurrent transmission of electricity and data are crucial. From the gigantic turbines harnessing wind energy to the precision-required realms of medical imaging equipment, these slip rings ensure that processes run smoothly, efficiently, and without the constraint of tangled wires or interrupted signals.

Brief Explanation of Through Bore Slip Rings

At their core, through bore slip rings consist of a set of concentric rings that are electrically conductive and capable of rotating around a common central axis. These rings maintain constant electrical contact with stationary brushes (or contacts) that transfer power and signal without interruption as the device rotates. The “through bore” aspect refers to the hollow section in the center of the slip ring, providing a passageway that can be used for various purposes, such as housing a shaft, facilitating additional conduits, or even integrating other machinery components.

Overview of the Article

This article aims to delve into the intricate world of through bore slip rings, providing readers with comprehensive insights into how these components work, what makes them so essential in today’s technology-driven landscape, and how to choose, install, and maintain them effectively. By exploring key attributes, cost considerations, and applications, and looking ahead to future developments, we aim to equip readers with a thorough understanding of through bore slip rings, whether they are complete novices curious about the basics or industry veterans seeking to brush up on the latest advancements. Through detailed explanations, practical advice, and answers to common queries, this guide seeks to illuminate the critical role that bore slip rings play in bridging the gap between the stationary and the rotational, ensuring the seamless operation of countless systems worldwide.

Understanding Through Bore Slip Rings

Through bore slip rings are marvels of engineering that epitomize the synthesis of mechanical and electrical design to overcome the challenge of providing a static to dynamic interface. These devices are not mere connectors but are pivotal to the operational integrity of systems requiring an unhampered rotational motion that must also support the transit of power, signals, or data.

Explanation of How Through Bore Slip Rings Work

Through bore slip rings operate on the fundamental principle of electrical connectivity maintained across a rotating interface. These devices create a bridge that facilitates uninterrupted power and data transmission between a stationary system component and another that rotates. Their working is akin to that of a traditional slip ring but with the distinct addition of an axial, cylindrical void—the through bore—which can be utilized for numerous purposes.

At the heart of their operation lies the continuous physical contact between the rings and brushes. As the machine to which the slip ring is attached rotates, the rings themselves also spin. Each ring is connected to a circuit within the rotating part of the machine. Stationary brushes, positioned in alignment with the rings and connected to the power or signal source, gently press against the rings. Due to this maintained contact, electrical current or data signals are transferred across the interfaces. Therefore, the electrical continuity is kept intact regardless of the rotation, speed, or direction of the spinning part.

The essence of a through bore slip ring is in this seamless conjunction of mobility and connectivity — it enables devices like robotic arms, wind turbines, and medical equipment to function without wire entanglement or restricted motion, significantly enhancing efficiency and expanding the capabilities of modern automated systems.

Description of Typical Parts and Their Function

The typical through bore slip ring is composed of several key components, each integral to its function:

- Rotating Rings (Conductors): These are the main body of the slip ring, usually fashioned from durable, conductive materials that rotate in unison with the machine’s moving part. They are responsible for carrying the electrical signal or power from the brushes to the rotating platform.

- Brushes (Contacts): Stationary and made of materials that ensure good electrical transmission, brushes rub against the rotating rings, maintaining constant electrical continuity as the rings turn.

- Housing: It encloses the mechanisms of the slip ring and offers protection from environmental elements like dust, moisture, or mechanical wear. This is particularly vital in harsh operating conditions.

- Bearings: These facilitate the smooth rotation of the rings. They are designed to withstand the load and rotational speeds specific to the application, playing a crucial role in the durability and performance of the slip ring.

- The Bore: Central to the through bore slip ring concept, the bore is a hollow space within the ring assembly through which other components like hydraulic lines, pneumatic columns, or even additional rotating shafts can be run, adding to the slip ring’s versatility.

- Lead Wires: Wires or cables that exit the slip ring on both the rotating and stationary sides, connecting the assembly to the system it serves.

The interplay of these components ensures that bore slip rings fulfill their roles efficiently, representing an optimized solution for industries that increasingly rely on sophisticated rotary systems. From providing meticulous control in robotic manufacturing lines to delivering reliability in the harshest conditions offshore, the through bore slip ring’s capacities are fully harnessed when their assembly, materials, and function are attuned to the demands of their specific application.

Key Attributes of Through Bore Slip Rings

Through bore slip rings stand as a testament to the ingenuity of modern electromechanical systems, embodying a range of key attributes that equip them for their crucial roles across various sectors. These devices are meticulously designed, with both their physical attributes and technical specifications tailored to meet the diverse and demanding requirements of applications that hinge on reliable rotary motion and data/power transmission.

Overview of Physical Attributes (Including Bore Size)

The physical attributes of through bore slip rings play a significant role in their compatibility and efficiency in specific applications. Among these, the bore size stands out as a critical feature. The bore size, typically measured in millimeters or inches, not only determines the capacity for central pass-throughs, such as mechanical assemblages or cabling but also directly influences the slip ring’s overall dimensions and mounting requirements. These dimensions span from compact designs, apt for constrained spaces in miniature equipment, to larger constructs necessary for heavy industrial machinery.

The material composition of both the casing and the conductive paths (rings and brushes) is another pivotal physical attribute. Materials are chosen based on their durability, conductivity, and resistance to environmental factors, ensuring longevity and consistent performance. For instance, the use of precious metals or alloys in the contact paths can enhance conductivity and oxidation resistance, factors crucial in high-speed data transmission scenarios.

Discussion on Technical Specifications (Such as Voltage, Current Rating, Rotation Speed, Signal Compatibility, etc.)

Moving beyond the physicalities to the heart of functionality, the technical specifications of through-bore slip rings underscore their adaptability and performance in operational settings:

- Voltage and Current Rating: These parameters are quintessential in defining the electrical capacity of the slip ring. They must be optimized to handle the power needs of the application without the risk of overheating or electrical failure. Variances in these ratings accommodate a broad spectrum of devices from low-power sensors to high-power industrial machinery.

- Rotation Speed: The capacity of through-bore slip rings to sustain their performance at various rotational speeds is crucial. This attribute, usually presented in revolutions per minute (RPM), must align with the operational speed of the machinery to avoid degradation of contact quality and, consequently, data or power transmission integrity.

- Signal Compatibility: With the proliferation of digital and analog signals in modern machinery, slip rings must be designed to accommodate specific signal types without distortion or loss. This involves the consideration of bandwidth, noise resistance, and the potential need for shielding.

- Environmental Specifications: The ability of a through bore slip ring to withstand environmental conditions such as moisture, dust, temperature extremes, and even corrosive substances is often detailed in its technical specifications. Protective measures, like sealing to IP (Ingress Protection) standards, ensure reliability across a range of environments.

These technical specifications are not standalone but interrelated. For example, a through bore slip ring designed for high-current applications might require specialized materials or cooling mechanisms to handle the increased thermal load, directly influencing the device’s physical design and operational limits.

The synthesis of these physical attributes and technical specifications forms the foundation upon which bore slip rings are evaluated, selected, and integrated into systems. Engineers and designers rely on this comprehensive understanding to make informed decisions that align with the operational demands and environmental conditions specific to their projects, ensuring that the chosen through bore slip rings enhance system performance and sustainability.

Choosing the Right Through Bore Slip Ring

The selection of the appropriate through bore slip ring is a nuanced process. The range of available slip rings on the market might seem overwhelming, but knowing the critical factors to consider can streamline the process and help you find the right fit for your application. Considering the rapidly evolving technical demands and the unique requirements of certain applications, sometimes a custom-designed slip ring might be the optimal solution.

Factors to Consider While Selecting a Through Bore Slip Ring

Here are some of the key factors that should guide your decision when selecting the best-fit through bore slip ring for your application:

- Load Type: Is the primary function of the slip ring to transmit power, data, or both? The type and nature of the load will influence the material selection for contacts, the circuit design, as well as other parameters like current and voltage capacity or signal compatibility.

- Operating Environment: The environmental conditions in which the slip ring will operate have a direct impact on its material and design requirements. Will it be exposed to harsh weather, dust, and chemicals, or must it be submersible? Understanding these variables can guide you toward slip rings with the necessary resistance or protection.

- Rotation Speed: The expected rotation speed of your machinery or equipment also influences your choice. High rotation speeds may require certain design modifications to ensure the ring maintains good contact with brushes.

- Bore Size and Overall Dimensions: You must also factor in the amount of available space for installing the slip ring and match that with the necessary bore size for your application needs.

In addition to these primary attributes, other considerations might include lifecycle expectancy, maintenance requirements, noise levels (for data transmission), compliance with standards, and, of course, cost-effectiveness.

Importance of Custom-Designed Slip Rings for Specialized Applications

In many cases, applications come with unique demands that can’t be met by standard through bore slip rings. To bridge this gap, manufacturers offer custom designs that can cater specifically to these unique needs. A custom-designed slip ring can incorporate specialized materials, unique electrical and mechanical configurations, proprietary signal handling schemes, or other tailored features.

For instance, in high-frequency communication applications, a custom slip ring design may involve specific noise reduction techniques and specialized contact materials for a high-speed data transmission environment. In medical imaging equipment where precise signal integrity is paramount, customization might mean the introduction of shielded circuits and the use of biomedical-grade materials.

In summary, the art of choosing the right through bore slip ring hinges on a keen understanding of your application’s demands and the capabilities of available equipment. For highly specialized needs, don’t shy away from exploring custom solutions – they can provide the surest path toward efficient, reliable, and long-lasting performance.

Installation and Maintenance of Through Bore Slip Rings

Proper installation and diligent maintenance are critical for the optimal performance and longevity of through-bore slip rings. Dependable operational functionality often hinges on these procedures. They are not merely perfunctory; instead, they constitute an integral part of the life cycle of these intricate electromechanical devices.

Basic Steps for Installation

The installation of a through bore slip ring typically involves several precise steps, all aimed at ensuring a reliable connection that facilitates smooth operation:

- Mounting Preparation: Begin with ensuring that where the slip ring is to be mounted is clean, and stable and that there’s adequate space for installation and future maintenance.

- Positioning the Slip Ring: Align the slip ring carefully with the rotational axis, ensuring the bore matches the host system’s shaft or central unit accurately.

- Securing the Stationary Part: Fix the stationary part of the slip ring (usually the housing) to a non-rotating part of the equipment, ensuring there’s little to no movement during operation.

- Attaching the Rotating Part: The part of the slip ring with the conductive rings is then secured to the rotating component of the application.

- Electrical Connections: Connect the lead wires from the stationary part to the fixed wiring and from the rotating part to the rotating platform’s circuitry, checking for proper wire lengths to avoid tension or excessive slack.

- Testing: Once installation is complete, it’s crucial to test the slip ring under operational conditions to confirm that it transmits power and signals effectively and without disruption.

Best Practices for Maintenance to Ensure Longevity

To maximize the lifespan of through bore slip rings, adherence to the following best practices in maintenance is essential:

- Regular Inspection: Periodically inspecting the slip ring for wear and contamination can prevent unforeseen failures.

- Cleaning: Keeping the slip ring clean, especially the contacts and brushes, is fundamental, as accumulation of debris can lead to poor conductivity.

- Lubrication: Some slip rings require occasional lubrication to maintain smooth rotation. Utilize the correct type of lubricant as specified by the manufacturer.

- Temperature Monitoring: Be aware of any abnormal temperature increases that could indicate overloading or friction issues.

- Electrical Testing: Regular electrical testing can help in the early detection of wear or faults before they lead to system failure.

Common Problems and Troubleshooting Techniques

Even with the most meticulous installation and maintenance, issues can arise. Identifying common problems and applying effective troubleshooting techniques become invaluable:

- Intermittent Connectivity: Look for signs of wear or poor contact between the brushes and rings. If required, clean the contacts or adjust the pressure of the brushes.

- Noise in Signal Transmission: This can be due to electromagnetic interference or a dirty contact surface. Shielding the slip ring and ensuring its cleanliness are potential fixes.

- Physical Wear or Noise: Excessive wear or noise might indicate insufficient lubrication or bearing failure. Inspect and replace bearings if necessary and ensure proper lubrication.

- Overheating: If the slip ring runs too hot, reassess the system’s electrical load to confirm it’s within the slip ring’s specifications. Overheating might also point to inadequate ventilation or environmental factors.

By meticulously following the steps for proper installation, diligently adhering to maintenance best practices, and being adeptly prepared to troubleshoot common problems, the operational reliability and longevity of through bore slip rings can be safeguarded. These protocols are crucial, not just for the functionality of the slip rings themselves but also for the predictable performance of the systems they serve.

Through Bore Slip Rings Cost Considerations

The cost of through bore slip rings is a critical aspect, impacting not only the initial procurement but also the long-term operation and maintenance of machinery and devices where they are applied. Understanding the broad spectrum of cost considerations and how various factors might influence these costs can aid in making informed decisions tailored to budget constraints and value optimization.

Broad Discussion on the Cost of Through Bore Slip Rings

The purchase price of through bore slip rings can vary significantly, ranging from relatively inexpensive models for light-duty applications to high-cost versions designed for complex, high-performance tasks. This price variation is reflective of the diversity in application requirements, material costs, manufacturing complexities, and the levels of research and development invested.

When considering the cost, it’s also vital to account for the lifetime operational expenses associated with the slip ring. Lower-priced models may initially seem economical but could entail higher maintenance costs, more frequent replacements, or less efficient performance, leading to increased operational expenses over time. Conversely, a slip ring with a higher initial cost might offer durability, lower maintenance requirements, and superior performance, potentially translating to cost savings in the long run.

Factors Influencing the Cost

Several key factors can influence the cost of through bore slip rings, making it essential to weigh these elements according to project specifications and budgetary allocations.

- Physical Size and Complexity: Generally, larger slip rings with greater bore sizes or more complex internal mechanisms command higher prices. This reflects the increased material costs and the intricate manufacturing processes required.

- Customization: Tailor-made slip rings designed to meet specific application needs are usually more expensive than standard models. Customization can range from unique materials, precise electrical specifications, special coatings, or adaptations to fit unusual shapes or spaces.

- Technical Specifications: The required technical parameters such as voltage and current ratings, signal compatibility, speed tolerance, and environmental protection levels can also impact cost. Superior specifications usually come with a price premium due to the higher quality or specialized materials and technologies needed to meet them.

- Manufacturer and Brand Reputation: The cost can also be influenced by the manufacturer’s brand, reputation, and geographical location where the slip ring is produced. Reputable brands that are known for quality and reliability might price their products higher, partly due to the assurance of performance and longevity they offer.

- Supply Chain and Economic Factors: External economic factors, including material scarcity, inflation, and supply chain disruptions, can affect costs. For instance, a rise in the price of precious metals used in contact materials can lead to increased slip ring prices.

In summary, a multitude of factors can influence the cost of through bore slip rings, and understanding these elements is crucial for budgeting and project planning. By considering the long-term operational benefits in conjunction with upfront purchase costs, it’s possible to select a slip ring solution that offers the best balance between performance, reliability, and total cost of ownership.

Applications of Through Bore Slip Rings

Through bore slip rings play an essential role in numerous industries, offering a solution for transmitting both power and data between static and rotating parts. From everyday gadgets to heavy machinery, their applications span an impressive array of devices and fields, driving innovations and efficiencies in the modern world.

Overview of Industries and Devices That Benefit From Through Bore Slip Rings

Through bore slip rings find application across a multitude of industries and settings, and here are some notable ones:

- Wind Energy: They are instrumental in wind turbines, facilitating the transmission of power and signals from the nacelle to the blades.

- Industrial Machinery: Slip rings are generally used in equipment that involves rotation, like packaging machines, rotary tables, or cable reels.

- Medical Industry: Medical scanning devices like CT scanners and MRI scanners rely on these slip rings for efficient data and power transmission between rotating and stationary parts.

- Defense and Aerospace: Through bore slip rings are used in radar systems, satellites, gun turrets, and more, supporting robust, uninterrupted communications and power supply.

- Marine Applications: Underwater Remotely Operated Vehicles (ROVs) and submersibles use specialized slip rings for transmitting power and data beneath the ocean’s surface.

- Entertainment Industry: In amusement rides, theatrical stages, turntables, and broadcast equipment, slip rings enable smooth rotation and transfer of power and signals.

Real-world Examples Demonstrating Their Functionality and Advantages

Let’s explore a couple of real-world examples that illustrate the benefits of using through-bore slip rings:

- Wind Turbines: In a wind turbine, the hub, which carries the blades, rotates according to the wind direction, while the nacelle (generator housing) remains stationary. Here, a through bore slip ring is installed on the main shaft, ensuring an uninterrupted supply of power and consistent delivery of performance data, enhancing the efficiency of the turbine.

- CT Scanner: During computed tomography (CT) scans, the X-ray tube assembly rotates around the patient, and a slip ring transmits power to the rotating parts and sends the patient’s image data to the stationary computer. The use of through-bore slip rings in these machines facilitates the production of detailed, 360-degree images, improving diagnostic capabilities and patient outcomes.

In conclusion, bore slip rings play a pivotal part in the functioning of a vast array of devices across multiple industries. By enabling the seamless transfer of power and data between rotating and stationary parts, they enhance overall systems’ efficiencies and create opportunities for innovation in a wide breadth of fields.

The Future of Through Bore Slip Rings

As industries evolve and technologies advance, bore slip rings are also undergoing significant transformations. These developments are not only enhancing the performance and capabilities of slip rings but are also shaping how they will be selected, used, and maintained in future applications. Understanding the trajectory of these changes is crucial for anticipating future needs and challenges in various sectors.

Commentary on New Advances or Future Developments

The future of through bore slip rings is marked by several promising advances and technological shifts, including:

- Integration of Wireless Technologies: Innovations in wireless data transmission are being integrated with traditional slip ring technologies, potentially reducing mechanical wear and extending the lifespan of these components.

- Materials Science Advancements: The development of new materials and coatings promises to enhance the durability and efficiency of slip rings, minimizing electrical noise and improving signal integrity even in harsh environments.

- Miniaturization and Customization: As devices become smaller and more complex, there is a growing demand for slip rings that are not only compact but also highly customizable to fit specific applications, leading to more specialized production techniques.

- Smart Monitoring Systems: The integration of sensors and IoT (Internet of Things) capabilities into slip rings enables real-time monitoring of performance data, predictive maintenance, and troubleshooting, enhancing reliability and minimizing downtime.

- Renewable Energy Influence: The push for more sustainable energy solutions is driving innovation in slip rings for use in renewable energy technologies, particularly in wind and tidal energy sectors, to handle higher power loads and improve efficiency.

How These Might Affect Selection, Use, and Maintenance of Through Bore Slip Rings

The aforementioned developments are set to significantly affect various aspects of through bore slip rings, from selection to operation and upkeep.

- Better Informed Selection Processes: Enhanced materials, designs, and integration capabilities mean that the selection process will increasingly focus on specific application needs, energy efficiency, and long-term operational savings, beyond initial costs.

- Ease of Use with Smart Technologies: The adoption of smart monitoring and wireless technologies will simplify use, allowing for real-time adjustments and optimizations, potentially remotely, thus enhancing operational flexibility and system responsiveness.

- Simplified Maintenance and Increased Reliability: Smart monitoring systems integrated into slip rings will enable predictive maintenance, alerting operators before failures occur. This advancement, coupled with materials that reduce wear, will significantly enhance reliability and reduce maintenance needs.

- Sustainability Considerations: With a growing emphasis on sustainability, future developments in slip rings will likely prioritize energy efficiency and the use of environmentally friendly materials, affecting selection criteria towards greener options.

In essence, the future of through bore slip rings is closely linked to broader trends in technology and sustainability. As these components evolve to become smarter, more durable, and more efficient, their impact will extend beyond functional improvements, influencing selection criteria toward more sustainable, reliable, and maintenance-friendly options. This evolution will ensure that slip rings continue to play a pivotal role in the advancement of mechanical and electrical systems across a myriad of industries.

Conclusion

Through bore slip rings embody a remarkable blend of simplicity, functionality, and versatility. As we have explored their many facets—from basic operations, and choice considerations, to futuristic projections—their pivotal role across diverse applications becomes indisputably clear.

FAQs about Through Bore Slip Rings

Q: Can through-bore slip rings transmit data as well as power?

A: Yes, they are designed to seamlessly transmit both power and data signals, supporting a vast range of applications.

Q: How long do through bore slip rings last?

A: With proper maintenance, bore slip rings can last for many years, although their lifespan will depend on several factors including the operating environment and usage intensity.

Q: Are custom through bore slip rings significantly more expensive than standard models?

A: While custom solutions tend to be pricier due to the costs associated with customization to meet specific requirements, they often offer greater value by perfectly aligning with the application’s needs.

Q: What exactly is a through-bore slip ring?

A: A through-bore slip ring is an electromechanical device designed to transfer power and data between a stationary part and a rotating one. It features a hollow shaft, known as the “bore,” which allows for the passage of cables or shafts, thereby providing a continuous connection regardless of movement.

Q: How do I determine the correct size of a through-bore slip ring for my application?

A: The correct size of a through-bore slip ring depends on the size of the shaft or conduit it needs to accommodate. Ensure that the bore diameter exceeds the outer diameter of whatever you’re passing through it. You should also consider additional factors such as the required circuit count, voltage, and current ratings, as well as the physical space available for the slip ring in your design.

Q: Can through-bore slip rings be used for transmitting data signals?

A: Yes, through bore slip rings can be designed to transmit not only electrical power but also various data signals, such as Ethernet, USB, and other communication protocols. They are outfitted with special materials and shielding techniques to maintain signal integrity.

Q: Are through bore slip rings available with different IP ratings?

A: Through bore slip rings come with various Ingress Protection (IP) ratings to suit different environments. The IP rating indicates how resistant the device is to elements like dust and water. It is important to select a slip ring with an appropriate IP rating based on the operating conditions it will be exposed to.

Q: Can I customize a through-bore slip ring to suit my specific requirements?

A: Absolutely. Many manufacturers offer customizable options for through-bore slip rings. This can include custom circuit configurations, housing materials, wire types, IP ratings, and more to suit the unique demands of your application.

Q: What maintenance is required for a through-bore slip ring?

A: Through bore slip rings may require periodic maintenance, including cleaning and possibly the replacement of worn components. The specific maintenance schedule and procedures depend on the application, the environment, and the manufacturer’s recommendations. Some advanced slip rings designed with maintenance-free features minimize the need for this upkeep.

Q: How long can I expect a through-bore slip ring to last?

A: The lifespan of a through-bore slip ring can vary widely depending on its build quality, environment, and usage. In general, high-quality slip rings designed for heavy-duty applications can last many years. Always refer to the manufacturer’s expected lifespan and warranty for a more accurate estimate.

Q: What should I do if my through bore slip ring starts to show signs of wear or malfunction?

A: If a slip ring exhibits signs of wear or malfunction, such as erratic electrical continuity or increased electrical noise, it’s advisable to first consult the troubleshooting guide provided by the manufacturer. For further assistance or to avoid any risks, reaching out to the manufacturer or a professional technician for an evaluation or repair is recommended.

See What We Can Do