A turret slip ring, a fundamental component in numerous systems, ensures seamless transmission of electrical power and various types of data signals. This cutting-edge technology underpins the mechanisms of advanced machinery used in a broad spectrum of industries, from communication systems to heavy machinery and defense.

Introduction to Turret Slip Rings

Essentially functioning as an electromechanical device, a turret slip ring links stationary and rotating sections of equipment together. It allows for an unrestricted, continuous 360-degree rotation while ensuring reliable electrical connectivity. Through this method, it is able to transmit power and data from a stationary object to a coinciding rotating object, making it a vital enabler for applications that need to rotate without obstructions and interruptions.

The use of turret slip rings goes far beyond enabling rotation. In numerous systems that operate in a cyclic pattern, carrying out functions such as scanning, revolving, and rotating become essentially impossible without using turret slip ring technology. Thanks to their design and capability, they play an integral role in many turret systems today, ensuring these systems carry out operations without the fear of tangled wires or a general break in power or data transmission.

Their role in turret systems, ranging from radar units to wind turbines, to rotating tanks in the defense sector, cannot be overstated. They ensure that these systems can perform necessary functions efficiently and with a high level of integrity, despite the rotational or oscillatory motion involved in these operations. By providing a reliable transmission of power and data signals, they help these turret systems maintain a high level of operational readiness and productivity, contributing significantly to these systems’ overall efficiency.

In a world increasingly dependent on complex technology, the importance of components such as turret slip rings becomes clearer. They stand as a testament to how innovative advancements can drive functionality, ensuring that even as parts move and rotate, the flow of power and information remains constant.

Design and Functionality Turret Slip Rings

When delving into the design characteristics of turret slip rings, one can’t help but appreciate the profound sophistication and thought that goes into these fairly small yet indispensably potent creations. Primarily, they are meticulously designed to withstand the challenges brought forth by their operating environments, whether in extreme temperature conditions, high-speed applications, or high-vibration settings.

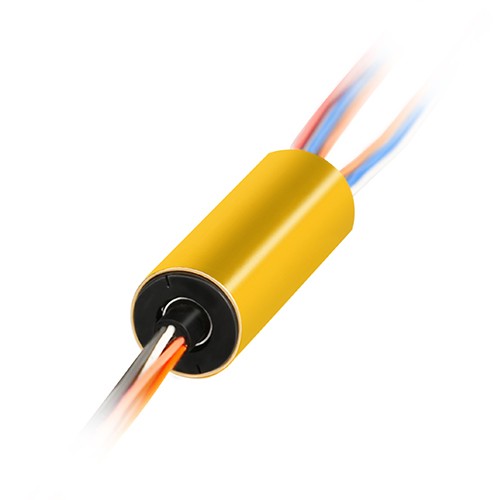

Typically, a turret slip ring is composed of stationary and rotating parts. The stationary side, or the stator, houses the inputs and outputs for power and signal. Meanwhile, the rotor connects to the revolving part of the device. This overall design remains more or less consistent across different types of turret slip rings.

At the heart of a turret slip ring lies its contact technology. Contact materials, invariably precious metals due to their superior conductivity and resistance to corrosion, are used at the interface between stationary and rotating parts. This enables an efficient and stable transfer of electrical signals or power between the two.

Modular design is another appealing aspect of modern turret slip rings. They are designed with separate modules for power and signal transfer, each tailored for specific capacity and data rates. This allows the same base unit to be customized for diverse applications, enhancing the slip ring’s versatility.

Understanding the operational mechanism of turret slip rings involves picturing a seamless, unbroken flow of power or data, even as parts of a system whirl around a fixed axis. Electrical signals and power are transferred via the physical contact between rotating and stationary surfaces, facilitated by the aforementioned contact technology. As the rotor spins, power or data signals set in motion by the stator are transferred across these contact points, maintaining their continuous flow.

This operational prowess emphasizes the fact that turret slip rings are not just rotating devices but also dynamic data and power transmission conduits. They are an ingenious solution to the complex challenge of ensuring an uninterrupted flow of power and data in systems that work around a rotational or oscillatory motion. Ensuring minimal signal loss and electrical noise, the slip rings, thus, support the normal functioning and efficiency of numerous applications across various industries.

Types of Turret Slip Rings

Just as there are various applications where turret slip rings find utility, there is also a wide array of slip ring types to cater to these diverse needs. Classification of these slip rings is usually based on parameters such as the application in which they are used, their design, and the material from which they are made.

The sheer variety of applications necessitates different types of turret slip rings such as those designed for simple rotating displays, high-definition video systems, intricate radar systems, and more. For instance, you might find compact capsule slip rings in CCTV cameras, while large industrial equipment might call for heavy-duty through-bore slip rings.

Design-wise, the variations are as wide as the applications. Some slip rings are designed as flat disc-style, ideal for space-constrained applications. Through-bore or hollow shaft slip rings feature a central hole that allows for routing hydraulic pneumatic pipes or shafts. Pancake slip rings are compact with layers stacked vertically, suitable for applications that require high speed but have strict height restrictions.

Material choice is another significant classifier. It directly influences the slip ring’s efficiency and longevity. The contact material, for example, is chosen for its conduction properties and resistance to wear and tear. Gold contacts are perceived as superior due to their minimal noise and resistance, along with oxidation resistance. Silver and copper are also used and chosen for their cost-effectiveness.

To understand each type better, let’s take for instance capsule slip rings; these are essentially used in low-current applications that require a compact form factor. In contrast, through-bore slip rings are designed with a hole in the center to accommodate additional components like shafts or cables, making them suitable for more complex applications.

Design, material choice, and type all coalesce to create a particular slip ring’s capabilities and characteristics, influencing its compatibility with a specific application. Understanding these variables is essential in selecting the most appropriate slip ring, balancing functionality, and long-term operational feasibility.

Turret Slip Rings: Key Applications and Industries

The versatility of turret slip rings extends to a wide range of industries and applications, owing to their unique ability to provide power and data transfer between rotating and stationary components. These slip rings have become indispensable in many advanced systems, contributing to the overall robustness and operational efficiency in various sectors. Below, we delve into some of the key applications and industries where turret slip rings are most commonly used and the specific reasons behind their prevalence in these areas.

Defense

One of the most significant applications for turret slip rings lies in defense systems. They play a critical role in many military-grade tracking and targeting systems, radar and optical equipment, and gun turrets. Irrespective of land, sea, or air-based operations, turret slip rings are chosen for their reliability in ensuring smooth data and power transmission, even in harsh environments and during challenging maneuvers.

Wind Turbines

Renewable energy generation, specifically wind turbines, employs turret slip rings to facilitate power and signal transmission between the nacelle and the stationary tower. Their role in maintaining an obstruction-free rotational motion is crucial in harnessing wind energy efficiently. The slip rings are chosen for their durability, corrosion resistance, and low-maintenance requirements, which are incredibly important factors in the typically remote and hard-to-reach locations of wind turbines.

Heavy Machinery and Robotics

In industries such as aerospace, automotive, steel, and mining, heavy machinery often relies on turret slip rings to function optimally. Additionally, robotic systems that involve rotational movements like robotic arms make extensive use of these slip rings. The primary reasons for their selection in such applications include their compact design, robust nature, and stable power and signal transmission during motions like swiveling and pivoting.

Medical Equipment

Turret slip rings play an indispensable role in various medical equipment, from CT scanners to surgical robotic systems. In these highly sensitive applications, slip rings are chosen for their ability to support high-speed rotation without generating noise or signal interference that may otherwise compromise the integrity of medical processes and accurate diagnosis.

Communication Systems

Communication systems, including satellite dishes, antennas, and remote-operated cameras, often depend on turret slip rings to deliver power and data signals as they rotate and adjust their positions. Chosen for their low-noise performance, reliability, and maintenance-free operating life, they greatly enhance communication and broadcasting systems.

The wide-ranging applications and industries mentioned above barely scratch the surface of where these innovative and versatile components are employed. Turret slip rings, with their unique design and functionality, cater to diverse application requirements and overcome the challenges associated with rotating equipment, making them an ideal choice for uninterrupted power and data transmission across sectors.

Turret Slip Rings: User Concerns and Solutions

Investment in turret slip rings can bring forward a range of user concerns and questions regarding product lifespan, maintenance, operational efficiency, and cost. Understanding these concerns and proactively addressing them with expert solutions can go a long way in ensuring user satisfaction and optimal utilization of turret slip rings.

Product Lifespan

A common concern among users is the lifespan of the turret slip ring. Due to the highly rotational nature of its operation, wear and tear over time seems inevitable. However, this concern is effectively addressed by the manufacturers, who typically make use of high-quality, durable materials that are capable of withstanding constant rotation without significant degradation. Slip rings made with gold contacts exhibit superior longevity due to gold’s inherent properties of low electrical resistance and high corrosion resistance. Always ensure to check the product specifications for estimated life cycles from the manufacturer.

Maintenance

Maintenance can be seen as a daunting task, especially in applications where the turret slip ring is embedded deep within a larger system. However, most modern slip ring designs incorporate features that require minimal or no maintenance. The use of optical and contactless techniques in advanced slip rings eliminates physical wear and tear, which is a primary cause of reduced performance and the need for maintenance.

Operational Efficiency

Ensuring operational efficiency is paramount for all users. Factors influencing a turret slip ring’s efficiency include resistance, noise during transmission, and the stability of the signal or power transfer. Generally, noise and signal stability concerns can be significantly reduced by choosing slip rings using precious metal contacts. For applications requiring high-speed data transfer, it is best to opt for slip rings designed specifically for high-frequency signals or data, such as Ethernet slip rings.

Cost

The cost of turret slip rings can vary based on factors like the type, size, material, and overall quality. While the initial purchase cost might seem high for certain high-quality slip rings, it is important to consider the long-term ROI. High-quality, durable slip rings often reduce maintenance and replacement costs over time and deliver reliable performance. Cost should be evaluated based on both immediate and long-term factors, including operational stability, longevity, and maintenance needs.

On a final note, considering the diversity in turret slip ring designs and their applications, it is always recommended to discuss specific requirements and concerns with skilled manufacturers or suppliers. Their expertise and guidance can ensure users find the most suitable weaponry in their resource arsenal, the humble yet potent turret slip rings.

Turret Slip Rings: Performance Metrics and Selection Criteria

Deciding on the right turret slip ring requires an understanding of specific performance metrics that dictate the functionality of the component. Awareness of these measurements can guide users toward an informed choice that best suits their requirements. In this section, we explore the crucial performance metrics and key selection criteria for turret slip rings.

Performance Metrics

A few essential metrics to evaluate while comparing turret slip ring models include:

- Max Speed: This indicates the maximum rotations per minute (RPM) the slip ring can handle without affecting performance or longevity. The required max speed should align with the system’s needs in which the slip ring will be installed.

- Number and Type of Circuits: The number of circuits signifies the capacity for transferring power or data signals. Some applications may require separate circuits for signal and power, or for different data signals.

- Dielectric Strength: This measurement shows the slip ring’s ability to resist electric breakdown, a critical feature for high-voltage applications.

- Insulation Resistance: A higher insulation resistance is often preferable as it reduces electrical noise that could interfere with data or signal transmission.

- Noise Level: In data and signal transmission, lower noise indicates a more precise and efficient transfer.

Selection Criteria

While performance metrics provide the technical backbone for the selection process, there are also some qualitative aspects to consider. Here are a few vital criteria:

- Application: Understand the specific requirements of your application. Each application might have a unique set of demands such as rotation speed, data transmission rates, power inputs, and outputs.

- Environment: Consider the environment in which the slip ring will operate. If it’s likely to be exposed to harsh conditions like extreme temperatures or moisture, a slip ring with a high IP rating (for dust and water resistance) will be suitable.

- Material: The choice of material impacts the slip ring’s durability, efficiency, and longevity. While gold is considered superior due to its low electrical resistance and high corrosion resistance, silver and copper contacts may also serve well depending on the application.

- Installation Space: The available space for installing the slip ring will limit the size and possibly the type of slip ring you can choose. Compact designs like capsule slip rings could suit applications with limited space.

- Manufacturer Support: Lastly, the availability of after-sale service and technical support from the manufacturer can be crucial in the long run.

By carefully examining these performance metrics and selection criteria, users can ensure they select a turret slip ring that not only meets their current needs but also stands the test of time while providing reliable service.

Turret Slip Rings: Future Trends and Developments

The landscape of turret slip ring technology, like many other areas of engineering, is consistently evolving in tune with advancements in related fields. Looking to the future, we can forecast trends that can significantly refine the functionality of turret slip rings, in turn, revolutionizing industries that heavily rely on this technology. Here, we explore potential future advancements and their impact.

Potential Future Advancements

- Smarter Design: As industries grow increasingly competitive and more reliant on efficient, compact technology, there is a clear trend toward integrating more advanced features into turret slip rings. For instance, many manufacturers are already working on making slip rings that are smaller in size, lighter in weight, and more energy-efficient.

- Higher Data Rates: With the exponential growth in data generation and the push for real-time analysis, there’s a surge in demand for slip rings that can handle higher data transmission rates than current standards.

- Automation and IoT Integration: With automation and the Internet of Things (IoT) ushering in a new era of digital transformation, smart slip rings with self-diagnostic and machine-to-machine communication capabilities are likely to become more prevalent.

- Materials and Manufacturing Techniques: The ongoing research into new materials and efficient manufacturing techniques is promising to lead to slip rings with even better performance, longevity, and environmental resistance capabilities.

Impact on Industries

The brilliant leaps that lie ahead for turret slip ring technology are likely to cascade into the industries that heavily rely on them.

- Defense: With advancements in high-speed data transmission and automation capabilities in slip rings, defense industries can look forward to enhanced targeting and tracking systems, reinforcing their strategic and tactical potential.

- Renewable Energy: The evolution towards more efficient and durable slip rings will contribute to the reduction of operational downtimes in wind turbines, thereby boosting overall energy generation and contributing to more sustainable and reliable renewable energy infrastructures.

- Robotics and Manufacturing: Improved data transmission rates coupled with smarter, automated slip rings could lead to significant advancements in robotic systems, thus automating more complex tasks, improving efficiency, and reducing errors in various manufacturing sectors.

- Healthcare: By carrying forward the trends of miniaturization and increased data transmission rates, medical equipment, particularly in diagnostic imaging where slip rings play a critical role, can enhance their precision and diagnostic abilities, thus driving forward improvements in patient care.

As these technological advancements materialize, so too will their potential for revolutionizing industries that utilize turret slip rings. By staying attuned to these evolving trends, businesses and industries can capitalize on opportunities and ensure they remain at the forefront of their industries.

Conclusion

Turret slip rings serve an indispensable role in smooth functionality across countless applications. As technology advances, these components promise even more efficiency, reliability, and versatility, making them a key area to watch for future industry progress.

See What We Can Do