Firstly, slip rings are inevitable, especially in rotating equipment. In any rotating machine that requires transmission of power and signal, a slip ring comes in handy. That is because the slip ring acts as a linking medium. Moreover, it helps transmit the energy or signal between the stationary and the rotary part. So, how many types of slip rings are there, and where are they used? Read along to know more.

Slip Ring and Its Types

To understand the type and usage, you must know what a slip ring is, right? In simple terms, a slip ring is an electrical, mechanical device that transfers electricity from a rotating generator shaft to a stationary cable in the nacelle. As a result, it maintains a smooth flow of current in the equipment. Slip rings are in everyday use now. For devices to be active and productive in manufacturing and other applications, a manufacturer has to choose the right slip ring to use and subsequently put it in the correct usage. However, how many types of slip rings are there?

Types of Slip Rings

There are many types of slip rings in the market. Then, what makes them different? The difference comes in the distribution of rings and electric conduction. Therefore, it depends on the location of the metal rings and conductor, which is the brush. Similarly, it also depends on the electricity to transmit and where it is going to be used. The following are the broader categories of slip rings available:

Shaft Slip Rings

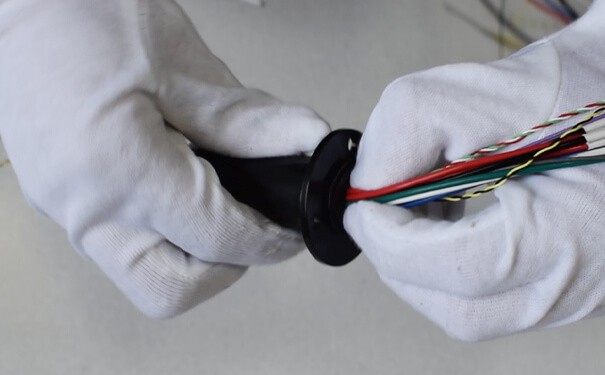

By appearance, these slip rings look like rods. The manufacturer distributes the rings along the axial direction. The rings can be many or fewer depending on the use and manufacturer’s preference. To clarify this, the more the rings are stacked, the longer the length. Similarly, the more the width of the ring, the wider the contact area. The shaft slip rings are highly reliable when in use as they are practical and easy to maintain. The rings in the shaft slip rings have an insulating sheet to isolate them. The shaft type has the contact brush distributed on the outer side of the rings. As a result, it ensures reliable contact between the electrical brush and the ring surface. To sum up, the following are slip rings that fall in this broader category:

- Capsule Slip Rings

- Through-hole Slip Ring

- Partial Capacitance

Disk Type Slip Ring

In this type of slip ring, manufacturers arrange conductors on a flat disc to act as rings on the rotating shaft during the manufacturing process. These slip rings are ideal for electric conduction in narrow spaces and highly constrained areas. So, how do these slip rings work? The rotor part of the electromechanical devices uses a series of concentric rings to load currents and signals. Moreover, manufacturers place insulating materials to separate the concentrate rings and brushes. But how efficient are these rings? Firstly, the disc types are the best when space is limited. Secondly, the continuous stacking of the conductors may lead to the tearing of the rings when the slip ring is conducting signals and current. That results in the brushes getting much dust further increasing the cost of maintenance. There are various disc-type slip rings available in the market, for example:

- Mercury slip rings

- Pancake slip rings

Differential Slip Rings

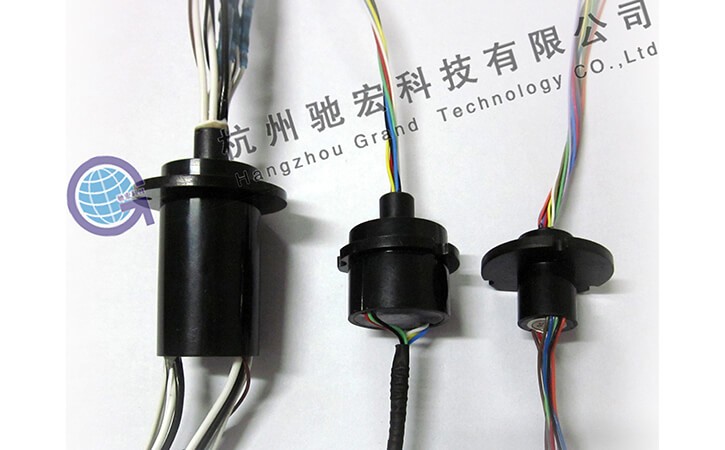

These types of slip rings are unique. For instance, they come with a unique structure that makes the device highly efficient and reliable. The core rings in the slip rings are also unique in the way manufacturers place them to guide the contact points. They are a result of high manufacturing technology. Therefore, they are more complicated than any other slip rings. The difference in design is what makes them efficient in various environments, voltage capacity, and uses. For example, manufacturers of military devices and CCTV cameras can use these rings. That’s because these devices get very little space for the installation. Some types of differential slip rings include:

- High voltage slip rings

- Tiny or manufacturer slip rings

- Fiber optic slip rings

Slip Ring Uses

Manufacturers produce slip rings for use in different places. Likewise, buyers buy them to use in making equipment with rotating parts. How do you know the right slip ring to use in a particular application? The right one depends on:

The Environment

We use devices in different contexts. Buyers and manufacturers must have an idea of the environmental conditions where the slip ring will work. Thus, they can be waterproof, tiny, or pancake-like, depending on the placing point.

Voltage to Transmit

The voltage means a lot when putting a slip ring in use. Above all, the energy passing from the stationary cable to the rotary equipment must be right to avoid any overload and malfunction of wires. The above factors affect the type of slip ring to use in machines. Manufacturers consider the above factors, and after that, use the slip rings in the following applications:

Making of Wind Turbines

It is the most common use of the slip rings. The blades in the turbine continuously move a rotating part. The rings transfer electricity generated by the rotor winding to the transformer.

Other Uses

There are many different uses of slip rings in the manufacturing sector, for example:

- Revolving automation and control systems

- Turbine, index tables, and robots

- Semiconductor processing

- CT and MRI medical scanners

- Manufacturing industries

- Set light communicators

- Printing and plastic molding

Final Thoughts!

There are many different types of slip rings. Also, their uses differ from the applications. Slip rings make equipment of rotating machines manageable and work efficiently. That is because it aids in the transmission of power between the moving part and the stationary one. Manufacturers assemble the essential elements depending on where the equipment works. That explains why there are many types of slip rings available in the market, as you have read above.

See What We Can Do