In the intricate world of automotive technologies, vehicular slip rings stand as a testament to the ingenuity of human engineering. From allowing pristine signal transfer to the continuous changing of rotational elements, they form the backbone of many modern vehicles, lending to their superior functionalities. This comprehensive guide explores the ins and outs of vehicular slip rings, translating complex terminologies into digestible knowledge for enthusiasts and professionals alike, ultimately decoding the science behind these critical components.

What are Vehicular Slip Rings?

To navigate through the complexities of vehicular technology, one must first acquaint oneself with its fundamental aspects. A key player in this realm is the vehicular slip ring.

Vehicular slip rings, or rotary electrical joints as they are often referred to, act as a bridge in connecting a static system to a rotating system within automobiles. But, what does this mean? Vehicles, especially those designed for heavy-duty tasks, include rotational parts that must maintain continuous operation. For instance, in an excavator, the cab where the operator sits and controls the machinery must rotate without hindrance. The vehicular slip rings come into play here, ensuring seamless transmission of power, data, signal, or even video across these rotating parts.

Comprising rings and brushes, these components allow a smooth, frictionless connection, making sure that there are no twisted cables or wires that could potentially disrupt the smooth operation of the vehicle. Crucial for both signal and power transfer, the vehicular slip rings provide a versatile solution to sustain multiple simultaneous connections while supporting the rotational movement.

In a nutshell, these unsung heroes work behind the scenes, hidden within the mechanics of a vehicle, enabling the efficient, uninterrupted operation that forms the heartbeat of any robust vehicular system. These components lay the groundwork for a broader conversation on vehicular technology and its constant evolution. As we delve deeper into other aspects of our comprehensive guide, this understanding of vehicular slip rings’ basic premise will only become more critical.

Importance of Vehicular Slip Rings

After having laid the foundation for vehicular slip rings and their basic functionality, it’s now time to delve deeper and shed light on why these components are so critical within the architecture of various vehicles.

In the absence of vehicular slip rings, it would be an immensely challenging task to achieve smooth and continuous rotation in vehicles, specifically those that require persistent rotation of certain parts for their normal functioning. A machine like an excavator, a crane, or even a military tank would experience hindrances, specifically due to tangled wires or disrupted signal and power transmission. This could not only affect the optimal performance but may even lead to untimely wear and tear or damage.

Vehicular slip rings step up to this challenge, offering seamless rotations by ensuring an uninterrupted connection between the stationary and rotating parts of a vehicle. By virtue of their design and functionality, they successfully transmit power, data, and signals even during the ongoing rotation process, without causing any operational disruptiveness.

Moreover, vehicular slip rings contribute significantly towards improving the overall performance of the vehicle. In an era where efficiency and sustainability are the key, these components support minimizing wasted energy, thus, leading to greater efficiency, not to mention the reduction in maintenance costs and enhanced durability resulting from the prevention of tangled wires.

In conclusion, vehicular slip rings, though a small component, bear a significant impact on a vehicle’s operational performance. Their ability to ensure continuous power and signal transmission, reduce maintenance needs, enhance durability, and improve overall vehicle performance is what makes them an indispensable part of modern vehicular technology.

How Vehicular Slip Rings Work

Understanding the function of vehicular slip rings is one thing, but to truly appreciate their importance, we need to examine the mechanics behind their operation. So, let’s observe the action behind the scenes and get a first-hand look at how these vehicular slip rings actually work.

The life of vehicular slip rings revolves around two main parts: the stator and the rotor. The stator is the stationary part of the system that usually consists of electrically conductive brushes. The rotor, on the other hand, represents the rotating components of the slip ring, which include several rings designed to carry power or signals.

As the motor driving the system fires to life, the rotor begins to turn, initiating the vehicle’s movement. The brushes of the stator stay in stable contact with the rotating rings, creating a continually rotating electrical channel through which electricity can flow.

The nature of the contact between the brushes and rings allows for the passage of electricity, which is used to power various parts of the vehicle. Functionally, the brushes maintain a steady sliding or rolling contact with the rings, allowing for the transmission of electrical signals from the stationary structure to the rotating parts and vice versa. This connection is what facilitates the seamless operation of rotating parts in a vehicle.

Just like a regular power cable, these slip ring assemblies are capable of transmitting a wide array of signals other than simple electricity, including data signals and video signals. The vehicle can, therefore, maintain an unrestricted and stable communication channel between its different parts, regardless of the rotations or movements they are making.

In essence, the primary operation and functionality of these vehicular slip rings boil down to maintaining unbroken contact, allowing power, data, and signals to flow freely and efficiently across the divide between fixed and rotating parts. Their ability to do this in all manner of vehicular architectures and systems renders them an irreplaceable centerpiece in the seamless operation and control of modern machines and vehicles.

Vehicular Slip Rings: Features

Just as a clear understanding of operational mechanics is essential, so is being aware of vehicular slip rings’ features that distinguish them from other electrical connectors. In this section, we will explore the key attributes that set vehicular slip rings apart and solidify their value in automotive engineering.

- High Rotational Speed Compatibility: Vehicular slip rings are built to withstand the demanding operational requirements of modern vehicles, which often exhibit high speeds of rotation, making them a reliable choice for applications that necessitate rapid movement.

- Low Electrical Noise: Noise disruptions and electrical interference can impair the quality and consistency of signal transmission. Vehicular slip rings are designed to minimize electrical noise, offering stable and uninterrupted power and data transfer even in demanding environments.

- Compact Size: The compact nature of vehicular slip rings ensures that they can be seamlessly integrated into various vehicle architectures without occupying excessive space. This makes them ideal for applications where saving space is imperative.

- Resistance to Vibration: The automotive industry often involves vehicles and equipment subject to powerful vibrations and constant motion. Vehicular slip rings are engineered to be robust, withstanding such vibrations without jeopardizing their functionality, thus maintaining performance in high-vibration environments.

- Operational Stability: One of the cornerstones of vehicular slip rings is their ability to operate consistently and stably over a wide range of conditions. The inclusion of precise positioning and orientation of brushes and rings, as well as careful material selection, contributes severely to their long-term reliability and performance.

- Environmental Adaptability: Vehicles often need to operate in extreme weather conditions and varying environments. Vehicular slip rings’ construction and design enable them to withstand such elements and continue to function effectively, making them a dependable choice across the automotive landscape.

In conclusion, the unique features of vehicular slip rings are what truly set them apart. From compatibility with high rotational speeds and resistance to vibration to low electrical noise and operational stability in rigorous environments, vehicular slip rings showcase an impressive array of attributes that ultimately contribute to their indispensable role in the automotive domain.

Vehicular Slip Rings: Benefits

From our comprehensive journey into understanding the structure, operation, and features of vehicular slip rings, it’s clear that these components hold great significance within the automotive industry. However, to truly ascertain the overall benefit these components bring, let’s explore the distinctive advantages vehicular slip rings offer to vehicle performance and overall operation.

- Smooth Operation: The ability to allow a smooth and continuous electrical interconnection between stationary and rotating parts of the vehicle is one of the earliest benefits of vehicular slip rings. It essentially eliminates the problems associated with tangled wires or cables, leading to improved vehicle performance and operation.

- Versatility: Vehicular slip rings can seamlessly transmit power, along with an assortment of signals including data, video, etc. Their ability to sustain multiple connections simultaneously supports a broad range of vehicle functionalities and improves the overall versatility of the vehicle.

- Reduced Maintenance: The inherent design of these components helps prevent wire tangling and related issues, leading to a noticeable reduction in maintenance efforts and costs. This is a key advantage, particularly in automotive applications where consistent performance and minimal downtime are crucial.

- Durability and Long Life Span: With a sturdy design and top-quality material selection, vehicular slip rings prove to be highly durable, ensuring prolonged and uninterrupted operation. Their ability to function under a myriad of environmental conditions further accentuates their lifespan, adding indefinitely to a vehicle’s longevity.

- Energy Efficiency: By facilitating a smooth flow of power and signals, vehicular slip rings reduce energy wastage and contribute positively towards the vehicle’s overall energy efficiency – an increasingly important concern in today’s eco-conscious world.

In a nutshell, the benefits of vehicular slip rings demonstrate their instrumental role in elevating vehicle performance. With attributes like versatility, reduced maintenance, longevity, and energy efficiency, they are undoubtedly critical components to consider for enhancing the operability and success of any vehicle application.

Vehicular Slip Rings: Types

Now that the significance, operation, features, and benefits of vehicular slip rings are well understood, it’s beneficial to discuss the diverse types available in the market. Indeed, vehicular slip rings aren’t a one-size-fits-all component. Different types have been designed to cater to an array of requirements, regarding signal types, voltage levels, number of circuits, and even the physical space available within different types of vehicles.

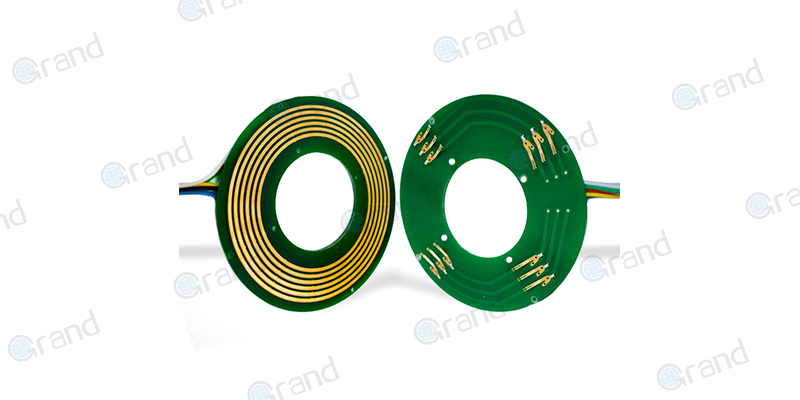

Through Hole Slip Rings

These are the most common type of vehicular slip rings, known for their hollow shaft through which other components (like shafts, leads, and pneumatic lines) can pass through. They ensure continuous transmission of power and signals and are perfect for scenarios where rotation is required around a central axis.

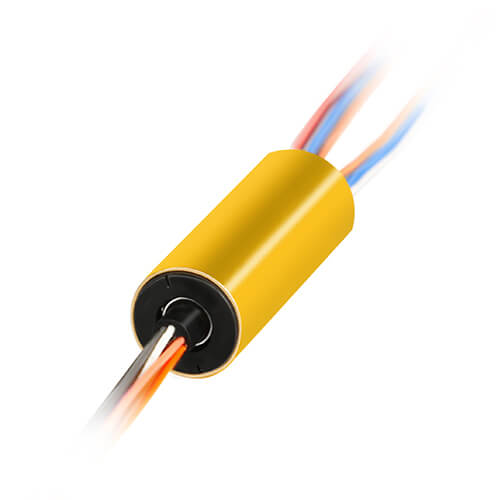

Capsule Slip Rings

Compact and efficient, capsule slip rings are well suited to small systems with limited installation space. They transmit all types of signals and are typically used in devices that require a high number of circuits in a compact space.

Pancake Slip Rings

Recognized for their flat, disc-like shape, pancake slip rings are typically used when length restriction exists within the system. While the design can introduce some challenges in terms of maintenance and performance at higher speeds, they are beneficial where axial space is confined.

Wireless Slip Rings

A rather modern design, these slip rings are used when physical connectivity isn’t possible. They transmit power wirelessly, making them useful for high-speed applications or those systems where a physical medium poses risk or disruption.

Fiber Optic Rotary Joints (FORJs)

Specifically designed for transmitting optical signals, FORJs are ideal for telecommunications, cable TV, and other high-speed data transfer applications where data transmission through fiber-optic cables is a necessity.

High Current and High Voltage Slip Rings

These slip rings are designed specifically for applications that involve high electrical loads. They are utilized in vehicles and machines that heavily rely on powerful electrical systems.

Exploring these types of vehicular slip rings demonstrates how varied and tailored these components can be. Ultimately, the use cases of the vehicle and its operationality dictate the type of slip ring that will bring optimal functionality and performance. Notwithstanding the type selected, vehicular slip rings remain a critical link in the seamless operation of our modern mechanical marvels.

Vehicular Slip Rings: Factors to Consider When Choosing

After an in-depth exploration of vehicular slip rings’ operation, features, benefits, and types, potential buyers might wonder how to select the most suitable one for their specific needs. Each slip ring comes with its own set of characteristics, benefits, and potential drawbacks. So how does one settle on the best choice? This section will serve as a guideline highlighting the most important factors to consider when choosing vehicular slip rings:

- Type of Signals and Power: The type of signals (data, video, audio, etc.) and power that need to be transmitted greatly influence the choice of the slip ring. Some slip rings are designed to handle only certain kinds of signals or power levels, hence one’s choice should be compatible with their specific requirements.

- Operating Environment: The environmental conditions under which the vehicle operates are another crucial factor. For instance, if the vehicle is likely to encounter harsh weather or extreme temperatures, the chosen slip ring should be capable of withstanding such unfavorable conditions.

- Physical Dimensions: The available space within the vehicle constrains the size of the slip ring that can be used. Smaller spaces require compact slip ring designs like capsule slip rings, while more generous spaces may use larger formats.

- Rotational Speed: The rotational speed of the vehicle’s moving components is another key aspect to consider when selecting a slip ring. Some slip rings are designed to perform optimally at high rotation speeds, while others are better suited for slower motion like in heavy machinery.

- Reliability and Durability: Choosing a slip ring that is robust and durable ensures longevity. Slip rings that require minimal maintenance and provide excellent performance consistency are generally preferred.

- Budget: Like in all purchase decisions, price plays a key role in the selection of a slip ring. While it’s imperative not to compromise quality for cost, balancing the two while considering the purpose of the slip ring is a practical approach.

In essence, selecting the perfect vehicular slip ring isn’t a one-step process but a combination of careful considerations that also include the estimated lifespan, maintenance requirements, and manufacturer reputation. Embracing a comprehensive evaluation of the above factors will undoubtedly aid in landing not just a good, but the perfect vehicular slip ring fit for your system.

Vehicular Slip Rings: Effective Maintenance Practices

As essential as vehicular slip rings are to the intended operation of vehicles, they’re not immune to wear and tear. Like all mechanical components, these slip rings require proper maintenance to ensure their longevity and consistent performance. This necessity leads us to the important topic of effective maintenance practices for vehicular slip rings. This section will guide you on key measures to consider for preserving and enhancing the lifespan of these pivotal components.

- Regular Cleaning: The buildup of dirt, dust, and debris could interfere with the performance of the slip ring. Carefully cleaning the brushes and the contact surfaces should be a routine maintenance practice to ensure smooth operation.

- Brush Inspection: Brushes are the key contact components in slip rings. Regularly inspect these brushes for signs of wear and tear. If they’re worn out, it is necessary to replace them to maintain optimal connectivity and signal transmission.

- Lubrication: Many slip rings require lubrication to reduce friction, prevent wear, and enhance the life cycle of the slip ring. However, this isn’t universal and would necessarily depend on the specific slip ring design and material.

- Avoid Moisture Exposure: Where possible, aim to keep slip rings dry. Moisture or water ingress can lead to corrosion or electrical shorts. If the slip ring isn’t designed for water-resistant operation, ensure it operates in a dry environment or is adequately protected.

- Temperature Checks: Excessive heat can cause damage to slip rings. Regular temperature checks can help ensure the slip ring doesn’t exceed its specified operating temperature range.

- Professional Services: Particularly for highly specialized or complex slip ring units, it can be beneficial to employ professional maintenance services. Professionals are typically better equipped and more knowledgeable to carry out inspections and conduct necessary repairs.

Undoubtedly, proper maintenance of vehicular slip rings plays a significant role in maintaining their operational efficiency over time. The practices highlighted above are neither exhaustive nor universally applicable, and it’s crucial to always refer to the specific maintenance instructions provided by the slip ring manufacturer. With regular checks, timely replacements, and adequate operational conditions, you can ensure the longevity and durability of your vehicular slip rings, thereby enhancing the overall efficiency and durability of your vehicle.

Vehicular Slip Rings: Widespread Applications

A deeper dive into the world of vehicular slip rings brings forth a broader perspective. From what they are, how they operate, and their benefits, types, selection considerations, and maintenance practices, it’s undeniable that these components boast a myriad of functionalities. However, to fully appreciate the scope of these components, let’s delve deeper into the widespread applications of vehicular slip rings in various industries and understand their practical utilization.

Automotive Industry

Being the heart of any moving vehicle, vehicular slip rings are fundamental in the automotive industry. They aid in the smooth operation of steering wheels, alternators, and electric cars’ motors, thereby ensuring efficient power and signal transmission.

Marine Industry

For seamless operation of shipboard systems like radars, sonars, or weapon systems that demand constant rotation, marine vehicles extensively use slip rings. The slip rings used in these scenarios are specialized to withstand harsh marine conditions.

Construction Machinery

In heavy-duty machinery like cranes, excavators, and concrete pumps that involve continuous rotation of parts, slip rings provide the essential connection to transmit power and control signals.

Wind Turbines

Slip rings play an integral role in wind turbines, where they carry electrical power from the stationary generator to the continuously rotating blades.

Medical Industry

Within the medical field, vehicular slip rings are used in CT scanners, MRI machines, and other revolving diagnostic equipment, allowing for the rotation of parts while maintaining a steady transmission of power and signals.

Robotics and Automation

Robotic arms, automated assembly lines, and other rotating equipment in production facilities often rely on slip rings to ensure a steady flow of power and signals whilst allowing flexibility in movement.

The numerous uses and applications of vehicular slip rings illustrate their likeness to silent workhorses, tirelessly and efficiently operating in the background within various industries. From automotive to marine, and even medical and automated industries, vehicular slip rings continue to facilitate the smooth operation of countless systems that we rely on daily. It’s an undeniable testament to their crucial role in ushering in a new era of technical advancements, making our lives easier, safer, and more connected.

Conclusion

In this voyage of exploring vehicular slip rings, after comprehending their fundamental operation, variations, key selection parameters, maintenance, and applications, it’s compelling to imagine – what’s next. The dynamic realm of technology never ceases to innovate, and vehicular slip rings are no exception. Here, we will shed light on some upcoming trends and developments that might further revolutionize the world of vehicular slip rings:

- Integration with IoT Devices: As the Internet of Things (IoT) continues to boom, there is an increasing trend towards integrating vehicular slip rings with IoT devices. This allows for improved diagnostics, remote control, and predictive maintenance capabilities.

- Wireless Power Transfer Slip Rings: As we move towards a wireless world, wireless slip rings are expected to gain more prominence. These slip rings can transmit power wirelessly, eliminating mechanical wear and increasing operating life.

- Miniaturization: With the continued trend of downsizing technology for efficiency and portability, miniaturized slip rings are likely to become more prevalent, especially in applications with space constraints.

- Slip Rings with Higher Voltage and Current Capacity: As electric vehicles and renewable energy sources continue to expand, the demand for slip rings capable of handling higher voltages and currents is expected to rise.

- Improved Material and Design Innovations: Advances in materials science could lead to the use of better, more durable, and high-functioning materials in slip rings—likely resulting in improved longevity, efficiency, and performance.

- Eco-friendly Slip Rings: With the global shift towards sustainability, the development of eco-friendly, energy-efficient slip rings made from recyclable or less harmful materials could become a significant trend.

As we embrace these advancements, it’s crucial to remember that the core principles underlying the operation of vehicular slip rings will continue to remain unchanged. The adaptations and upgrades will only aim at enhancing the performance, efficiency, and effectiveness of these indispensable mechanical devices. By staying prepared for these future trends, one can ensure to benefit from the best that vehicular slip ring technology has to offer, keeping pace with an ever-evolving technological world.

FAQs about Vehicular Slip Rings

As we tread the complex path delving into the workings, types, maintenance methods, and future trends of vehicular slip rings, we may encounter numerous concerns and queries that need to be addressed for a complete understanding. In order to aid further comprehension, we have consolidated and addressed some frequently asked questions related to vehicular slip rings in this section.

Q: Where are vehicular slip rings used?

A: Vehicular slip rings are commonly utilized in various industries including the automotive industry, marine applications, construction machines, wind turbines, medical equipment, and robotic systems, among others.

Q: How often do slip rings need maintenance?

A: The frequency of maintenance required for vehicular slip rings largely depends on their operating conditions, the type of application, and specific manufacturer guidelines. However, regular inspection and proactive maintenance are recommended for optimal performance.

Q: Are all slip rings the same?

A: No, slip rings can differ a lot based on their specifications, types, materials, size, capacity, the type of signals they transfer, and the application they’re meant for. It is important to consider these factors when choosing a slip ring.

Q: Can I use a slip ring in a high-temperature environment?

A: While standard slip rings may not withstand high-temperature environments, certain specialized slip rings are designed to operate effectively under high-temperature conditions. Therefore, the specifications of the slip ring should match the environmental requirements of the application.

Q: What are some future trends in vehicular slip rings?

A: Upcoming trends include the integration of slip rings with IoT, the development of wireless power transfer slip rings, miniaturization, slip rings with higher voltage and current capabilities, material and design advancements, and a focus on creating eco-friendly slip rings.

These are just some of the many questions revolving around this pivotal component in the field of vehicular technology. As the reader delves deeper into the subject or seeks to apply the slip ring concept practically, more questions might arise. Ideally, consulting with an industry expert or being directed by specific manufacturer manuals can provide further customized and professional insights. Nevertheless, this guide can serve as a cornerstone for understanding this complex yet crucially valuable component, the vehicular slip ring.

See What We Can Do