A Waterproof Slip Ring is a specialized device, specifically designed to work under moisture, corrosion, and underwater conditions. The protection grade will be IP65, IP67, and IP68, and the liquid components in the working environment such as freshwater, seawater, oil should be considered. Waterproof slip rings are widely used in ships, harbor equipment, and some water or moisture environment working conditions. The purpose of these rings is to facilitate the transmission of electrical signals, power, and various other forms of media between rotating and stationary parts.

The waterproof slip rings are encased in protective enclosures that shield the electrical slip ring from water, dust, dirt, debris, and damage. Additionally, these dustproof enclosures enhance the protection of the slip rings in harsh environments. These kinds of slip rings are designed to have long service lives and high-performance capabilities, ensuring reliable operation in challenging conditions.

What Is Waterproof Slip Ring?

Waterproof Slip Rings - FH Series

Available for Custom, Protective Grade IP 68

Slip rings of the FH series are specially designed for IP68 water-proof and dust-proof slip rings. Grand applies noble precious metal reduced noises and interference between circuits, low friction torque assures long life-span. Available in a wide range of sizes and models starting from 22mm up to over 100mm dimension.

Although GRAND offers modularized & standardized designs for various application solutions as an original slip ring manufacturer. To create your most suitable waterproof slip ring connector, please feel free to contact us.

Feature

◆ Waterproof slip ring, IP68, can work underwater of 1500M deep ocean, mainly applied to ships and oil wells

◆ Multi-point brush contact material ensure long life

◆ Anti-corrosion stainless steel housing for better protection

◆ Integrated structure design for easy installation

◆ Standard model and customization are available

◆ Standard model supports 1-96 rings power or signal(0~20A/ring)

◆ Free maintenance

Options

◆ No. of rings

◆ Current &voltage

◆ Connector

◆ Housing material

◆ Position of wire outlet, wire length

◆ Flange mounting is optional

◆ Operating temperature

◆ Support mixed high speed data transmission(including Ethernet, USB, Profibus, Ethernet, CANOPEN, CANBUS, RS232, RS485, etc.)

◆ Fluidic rotary joints, FORJ and electric slip ring can be mixed

Model Breakdown

What Else Do You Want To Know About Waterproof Slip Rings?

Purpose

Waterproof slip rings are engineered to ensure reliable performance in environments where moisture exposure is a significant concern. These devices facilitate the seamless transmission of power and data between stationary and rotating components, eliminating the risk of connection failures due to water ingress. By utilizing waterproof slip rings, industries can maintain continuous operation without interruptions caused by environmental conditions.

Protection Rating

The protective rating of waterproof slip rings is crucial in determining their suitability for various applications. With an IP68 rating, these slip-ring offer complete protection against dust ingress and can withstand continuous immersion in water beyond specified depths. This high level of protection makes them ideal for demanding environments where exposure to liquids is a routine occurrence, including the use of water treatment slip rings in various industrial processes.

Construction Features

Waterproof slip rings are constructed with robust protective enclosures that are specifically designed to shield the internal components from water, dust, dirt, and other contaminants. These enclosures are built to withstand harsh environmental conditions, ensuring that the slippring maintains its functionality over time. The durable materials used in the construction of the waterproof ring not only enhance the longevity of the ring slip but also ensure reliable performance under varying pressures and temperatures.

Contact Material

Many waterproof slip rings utilize gold-gold contacts, which provide excellent electrical conductivity and reduce contact resistance. This choice of material enhances the overall reliability and efficiency of the slip rings, minimizing wear and tear during operation. Gold contacts are particularly beneficial in environments where corrosion could compromise the integrity of electrical connections, ensuring consistent performance throughout the slip ring’s service life.

Installation

Designed for straightforward integration into a variety of systems, waterproof slip rings can be customized to meet specific operational needs and constraints. Their user-friendly design facilitates easy installation, allowing engineers and technicians to incorporate them into new or existing machinery with minimal effort. Customization options include varying sizes, configurations, and connector types, enabling users to select the most suitable slip ring for their specific applications. For instance, China IP65 waterproof slip rings are an excellent choice for applications requiring reliable sealing against dust and water.

Waterproof slip rings are essential components for maintaining reliable electrical connections in challenging environments, thanks to their robust design, high protection ratings, and advanced contact materials. Whether you are inquiring about is ring waterproof options or searching for waterproof rings for your specific needs, waterproof slip rings provide the reliability and durability necessary for effective performance.

Waterproof Slip Ring Application

Waterproof slip rings are used in several fields and industries that require reliable conductivity in water or damp conditions. Below are some of the typical applications:

Waterproof slip rings are used in several fields and industries that require reliable conductivity in water or damp conditions. Below are some of the typical applications:

- Maritime Equipment: Waterproof slip rings are indispensable in equipment used for offshore exploration, deep-sea salvage operations, naval defense systems, and maritime communication devices.

- Underwater ROVs (Remotely Operated Vehicles): These devices are often used for underwater exploration, archaeological digs, and various oceanographic research purposes. The slip rings help transmit power and signals from the surface to the underwater components.

- Outdoor Camera Systems: Waterproof slip rings are used in outdoor security and surveillance systems to provide rotational energy and enable signal transmission regardless of weather conditions.

- Wind Turbines: In wind energy systems, slip rings are used to transmit power and data signals between the stationary and rotating parts of the wind turbine.

- Water Treatment Plants: In such facilities, a waterproof slip ring is commonly utilized where equipment is consistently exposed to moisture and needs reliable power signal transmission.

- Food and Beverage Industry: Waterproof slip rings are used in automated cleaning systems where water resistance is a necessity.

Advantages of Waterproof Slip Rings

Waterproof slip rings provide several advantages that make them an essential solution in various industry applications. Here are some of their key benefits:

Durability and Longevity:

These slip rings are built to withstand challenging environments, including exposure to water, moisture, dust, and corrosion. Their robust construction enhances durability and allows them to maintain performance over extended periods, reducing the frequency of maintenance and replacement, which leads to cost savings in the long run.

Versatility:

Waterproof slip rings are compatible with a wide range of signals and currents, allowing them to transmit electrical power, data, and other media between stationary and rotating parts. This versatility makes them suitable for diverse applications across multiple industries, including marine, construction, telecommunications, and medical equipment.

Seamless Performance:

These slip rings can function seamlessly even underwater, providing uninterrupted signal and power transmission. Their ability to perform reliably in wet conditions is crucial for applications like marine equipment, surveillance systems, and industrial machinery, where uninterrupted connectivity is essential.

Minimal Maintenance:

Given their resistance to harsh conditions, waterproof slip rings require minimal maintenance, which helps to lower overall operating costs.

Protection Against Environmental Factors:

Waterproof slip rings are specifically designed to offer protection against moisture, dust, dirt, and debris. This feature ensures reliable performance without the risk of short circuits or component failure in applications exposed to water.

High IP Ratings:

Many waterproof slip rings come with high Ingress Protection (IP) ratings, such as IP67 or IP68, indicating their ability to withstand immersion in water and protection from dust ingress. This makes them suitable for underwater applications or environments with high humidity.

Customizable Designs:

Waterproof slip rings can be tailored to meet specific application requirements, including size, number of circuits, and connector types. This customization ensures a seamless fit into different systems and enhances overall functionality.

Ease of Installation:

Many waterproof slip rings are designed for straightforward installation, allowing for quick integration into existing systems. This ease of installation can minimize downtime and improve operational efficiency.

Enhanced Safety:

By preventing moisture ingress and potential electrical hazards, waterproof slip rings contribute to safer operational conditions in environments where water exposure is a concern.

Grand: Your Trusted Slip Ring Supplier

At Grand, we pride ourselves on being a leading slip ring supplier, specializing in bespoke slip ring solutions tailored to meet the unique requirements of various industries. Since our establishment in 2011, we have focused on delivering high-quality custom slip rings, including custom slipring and grand slip products, to enhance the performance of rotating systems.As a trusted slip ring suppliers, we collaborate closely with our clients to provide innovative solutions, making us a reliable slid ring supplier in the industry.

Expertise and Customization

With over 50 national patents and a robust portfolio, we understand that different environments necessitate specific performance parameters. Approximately 50% of our offerings are customized products, reflecting our commitment to providing tailored solutions. Our engineering team works diligently to ensure each slip ring is designed with precision, using high-quality materials to enhance durability and performance.

Quality Assurance

Quality is paramount at Grand. Our comprehensive quality management system follows strict protocols from the selection of raw materials to the final delivery of products. Our state-of-the-art testing center performs rigorous assessments, including temperature, salt spray, impact, and vibration tests, ensuring that every slip ring meets the highest standards of reliability and durability.

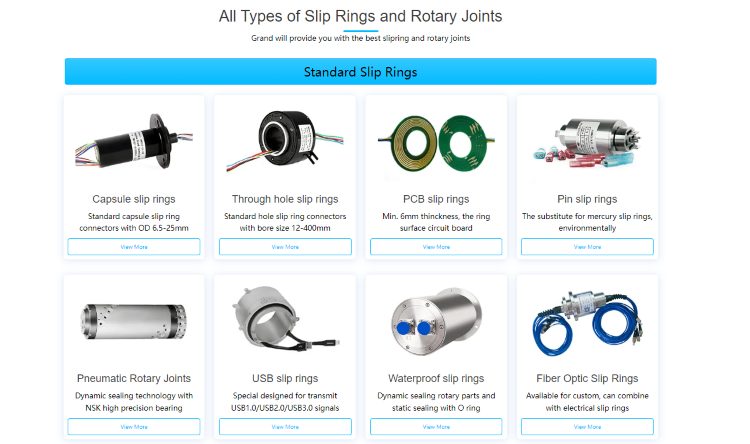

Extensive Product Range

As a trusted slip ring supplier, we offer an extensive range of products designed for various applications, including:

Electrical Slip Rings

Electrical Slip Rings

Through Hole Slip Ring

Capsule Slip Ring

Ethernet Slip Rings

Miniature Slip Rings

PIN Slip Rings

Fiber Optic(FORJ) RF Rotary Joint

Fiber Optic Rotary Joint (FORJ)

RF Rotary Joint

Rotary Joint

Specialized Slip Ring

Pancake Slip Ring

High Temperature Slip Ring

USB Slip Rings

High Speed Slip Ring

PCB Slip Ring

HDMI/SDI Slip Ring

High Voltage/High Current Slip Ring

Waterproof Slip Ring

Field Buses Slip Ring

Servo Encoder Slip Ring

Military Slip Ring

Optical Transmitter and Receiver

Our expertise in slip ring assembly manufacturers allows us to cater to the specific needs of our clients, ensuring optimal performance across these diverse sectors. We are also recognized among the top slip ring manufacturers in India, providing high-quality solutions for local and international clients.

Commitment to Innovation

Our focus on innovation drives us to continually enhance our products and services. We collaborate with leading universities and research institutions to develop advanced technologies that address the evolving needs of our clients.

When you choose Grand as your slip ring manufacturer, you are partnering with a company dedicated to quality, innovation, and customer satisfaction. Experience the Grand difference—where excellence in slip ring manufacturing is our standard, and your needs drive our engineering solutions. Contact us today to discuss how we can support your projects with reliable slip ring solutions, including through hole slip ring manufacturers and belt clip pin ring assembly suppliers China.

Related Posts

FAQs about Waterproof Slip Ring

Are slip rings waterproof?

Slip rings are not inherently waterproof; however, many manufacturers offer models designed to be water-resistant or waterproof for specific applications. The level of water resistance depends on the materials used in the construction of the slip ring and the sealing techniques employed. Typically, slip rings that are intended for use in harsh environments, such as marine or outdoor applications, are equipped with seals and gaskets to prevent moisture ingress. When selecting a slip ring for environments where exposure to water or humidity is a concern, it’s essential to consult the manufacturer’s specifications to ensure it meets the necessary IP (Ingress Protection) rating. An IP rating, such as IP67, indicates that the slip ring can withstand temporary submersion in water and dust ingress, making it suitable for more demanding conditions. Proper installation and maintenance are also crucial to ensuring the longevity and effectiveness of waterproof slip rings.

What is the best material for a slip ring?

The best material for a slip ring largely depends on the specific application and environmental conditions it will encounter. Generally, high-quality materials are essential to ensure optimal performance and longevity. Common materials used in slip ring construction include copper, gold, and silver for the contacts due to their excellent electrical conductivity and resistance to corrosion. Gold plating, in particular, is favored for high-performance applications as it reduces contact wear and enhances conductivity. The housing materials can also vary, with aluminum and stainless steel being popular choices due to their strength and resistance to corrosion. For extreme environments, specialized coatings or materials may be required to withstand high temperatures, moisture, or chemical exposure. Ultimately, selecting the best material involves considering factors such as electrical requirements, environmental conditions, and mechanical stresses.

What is the difference between slip ring and split ring?

The primary difference between a slip ring and a split ring lies in their design and functionality. A slip ring is a continuous electrical connector that enables the transmission of power and data between stationary and rotating components. It is designed to provide uninterrupted connectivity, making it ideal for applications requiring continuous rotation, such as in motors, robotics, and wind turbines. In contrast, a split ring is often used in commutation systems within electric motors and consists of two halves that make intermittent contact with brushes to transfer electricity. While slip rings maintain a continuous connection throughout rotation, split rings only make contact at specific points during rotation. This fundamental difference makes slip rings more versatile for applications requiring reliable and ongoing connections, while split rings are typically limited to specific motor designs.

What is the difference between collector ring and slip ring?

The terms “collector ring” and “slip ring” are often used interchangeably, but they can refer to slightly different components in electrical systems. A collector ring is a type of slip ring specifically designed to collect electrical current from a stationary source and deliver it to a rotating element. Collector rings are typically used in applications where there is a need to transfer power or signals while allowing for rotational movement, such as in rotating antennas or certain types of machinery. On the other hand, slip rings are broader in scope and can include various designs and configurations for different applications, including multiple circuits for data and power transmission. While both serve the function of transferring electrical signals, a collector ring may be a specific implementation of a slip ring design focused on collecting current, whereas slip rings can encompass a wider range of functionality and application versatility.

Want to know more about the benefits of our Waterproof Slip Rings? Complete the form, and we’ll provide a comprehensive overview.