High current slip rings and high voltage slip rings are used for communication devices, large machining centers, antenna radar systems, large cranes, mining machines, and large cable reels. High voltage sometimes requires more than 2,000 volts and high current sometimes requires 500 amperes.

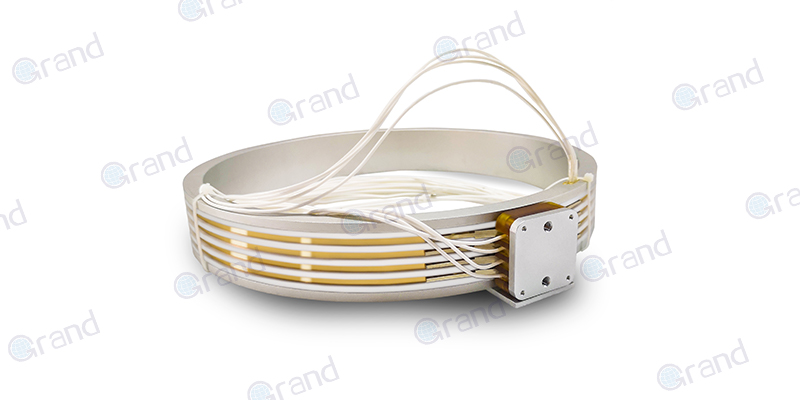

High Current/Voltage Slip Rings - DHG Series

Available for Custom, Max. 1000A, Max. 6000V

The insulation materials must have excellent conductivity, corrosion resistance, fatigue resistance, and lubrication performance. When designing the mechanical structure, the characteristics of large currents need to be considered, as well as the electrical insulation design, installation, and maintenance performance.

Although GRAND offers modularized & standardized designs for various application solutions as an original slip ring manufacturer. To create your most suitable high current/voltage slip ring connector, please feel free to contact us.

Feature

- Max. voltage up to 6,000 volts

- Max. ampere up to 1000 A

- Small contact resistance, low heat and long working life

- Aluminium alloy housing, easy installation

Option

- Operating speed

- No. of rings

- Current &voltage

- Installation size

- Connector

- Position of wire outlet

- Housing material

Model Breakdown

High Current Slip Ring Typical Applications

High current slip rings are integral components in many industrial and engineering settings. These devices aid in transmitting high current levels from a stationary to a rotating structure without hindering the rotation. Here, we’ll look at some typical applications where high current slip rings are often used.

High current slip rings are integral components in many industrial and engineering settings. These devices aid in transmitting high current levels from a stationary to a rotating structure without hindering the rotation. Here, we’ll look at some typical applications where high current slip rings are often used.

Wind Energy Systems

High current slip rings play a crucial role in wind turbines. They enable the transfer of high electrical currents from the rotating blades to the stationary nacelle, ensuring consistent power transmission even at high wind speeds.

Heavy Industrial Equipment

Heavy industrial equipment, such as cranes and excavators, utilize high current slip rings to transmit electric power to their rotating parts. For example, in excavators, high current slip rings can transmit power to the rotating cabin without affecting its movement.

Electric Vehicle Charging Stations

In electric vehicle charging stations, high current slip rings can be used in reel systems to enable safe and effective power transmission.

Generators & Alternators

In generators and alternators, high current slip rings transfer current generated from the rotating armature to the stationary load. They are essential for the efficient operation of these electrical machines.

Automotive Industry

High current slip rings are also used in electric vehicles, particularly in steering systems, where power needs to be transmitted from the stationary car body to the rotating steering wheel.

Marine and Offshore Platforms

In marine and offshore platforms where devices need to operate in challenging conditions, high current slip rings prove their reliability by facilitating the continuous operation of radar antennae, turrets, cranes, and propellers.

Amusement Rides

Amusement rides, especially rotating ones like carousels and Ferris wheels, need high current slip rings to provide power for lighting and other electrical systems while the rides are in motion.

High current slip rings are a critical component in many applications. As technology evolves, their applications in various industries are expected to further expand, supporting the continual advancement of machinery and engineering possibilities.

More Things You Want to Know About High Current Slip Rings

High current slip rings are engineered to provide efficient electrical connections in rotating machinery, particularly when high currents are required. These slip rings are designed as a cost-effective alternative to traditional mercury-based solutions, making them suitable for various applications, including heating elements and other high current devices. Their innovative design features unique channel brush technology, which reduces contact force between the slip ring’s brushes and rotor, significantly extending the unit’s lifespan.

The high rotational ring in the high current high voltage system ensures seamless connectivity, while the high voltage ring provides safety at 120V slip ring specifications, making it a reliable choice for any slip ring electric application, especially when paired with high speed slip ring for efficient performance and optimal data transfer through the slip ring electrical.

Key Features

Mercury-Free Construction: These electric slip rings eliminate the use of mercury, promoting safer operations and easier compliance with environmental regulations like CE and RoHS.

Current Capacity: High current slip rings can handle currents up to 20 amps, making them ideal for various high power slip ring applications. For even more demanding scenarios, high power slip rings are available, capable of transferring currents up to 1000A while ensuring safety and efficiency.

Compact Size: Designed for space-saving applications, these electric slip ring maintain a compact profile without compromising performance.

Durability: With low maintenance requirements and a long operational life, high current slip rings are perfect for continuously operating machinery.

Advanced Capabilities

Large Diameter Options: Large slip rings can exceed 70 inches in diameter, allowing for substantial power transmission in various configurations, such as platter or drum designs.

High Voltage Ratings: These slip rings are also available with high voltage ratings, reaching up to 1000V, suitable for demanding high voltage high current applications.

Mechanical Efficiency: The slip rings feature optimized brush and ring designs that ensure low contact resistance and quiet operation, crucial for maintaining system integrity.

Customizable Options: High current and high voltage slip rings can be tailored with various features, including circuits for simultaneous power and data transmission, lead wire length and direction, and housing color.

Applications of High Current Slip Rings

Wind Turbine: Ensure maximum energy output with high current slip rings that support substantial power transmission for turbine operations, even in harsh environments.

Robotic Arm: Enhance industrial automation with slip rings that deliver high current to robotic systems, ensuring reliable performance and efficient operation in heavy-duty applications.

Construction Machinery: Power heavy construction equipment with slip rings designed to withstand tough conditions while facilitating high current transmission for motors and other components.

Marine: Ideal for marine applications where high power is essential, these slip rings provide reliable power transmission to onboard equipment, ensuring optimal performance at sea.

Military: High current slip rings are crucial for military applications, delivering dependable power and signal transmission for advanced systems used in defense technologies.

Radar & Antenna: Optimize radar and antenna systems with slip rings that support high current transmission, ensuring real-time data transfer while maintaining system integrity during rotation.

Navigating the Power Slip Ring Market

The power slip ring market is experiencing significant growth, driven by the increasing demand for efficient power transmission across various industries. Power slip rings are essential for transferring power and data in rotating systems, making them critical in applications ranging from aerospace to industrial automation.

Key Drivers

Technological Advancements: Innovations in design and materials are enhancing the performance of power slip rings, which drives their adoption across different sectors.

Rising Automation: The push for automation in manufacturing and other sectors boosts the demand for reliable power slip rings to support automated systems.

Renewable Energy: The growth of renewable energy sources, particularly in wind and solar, necessitates efficient power transmission solutions.

Market Segmentation

The power slip ring market is segmented by type, including high current slip rings, which handle significant loads for applications like heavy machinery; high voltage slip rings, essential for safe power transfer in sensitive environments; and high-speed slip rings, designed for rapid operations in sectors like aerospace and robotics, ensuring reliable performance under demanding conditions.

By application, power slip rings are vital across various industries. In industrial machinery, they enhance efficiency by providing continuous power and data flow. In marine settings, they maintain reliable communication and power in rotating systems. Robotics relies on slip rings for precise movement control, while medical devices benefit from consistent power for imaging and diagnostics, highlighting the technology’s versatility.

Geographic Insights

The global power slip ring market is expanding, with significant contributions from North America, where strong manufacturing and automation adoption drive demand. Europe emphasizes innovation and quality, particularly in renewable energy. Asia-Pacific is rapidly industrializing, with growing automation and renewable projects, making it a vital region for slip ring applications and market growth.

Competitive Landscape

In the competitive landscape of the power slip ring market, we at Grand stand out by offering a diverse range of power slip rings tailored to meet various application needs. Our commitment to quality and innovation is evident in our extensive certifications and patented technologies. We strive to enhance performance and reliability while keeping costs competitive. Other manufacturers in the market also focus on similar goals, but we pride ourselves on our ability to adapt to evolving industry demands and provide exceptional solutions for our customers.

About Grand

Grand is a leader in the power slip ring market, dedicated to delivering quality and innovation. Our commitment is evident in our attainment of ISO9001, RoHS, CE, and GJB9001B certifications, confirming that our products not only meet but exceed military-grade standards. This emphasis on quality is further supported by our extensive portfolio, which includes numerous patents for slip rings and rotary joints, underscoring our focus on advanced technology and design excellence.

Collaborations and Partnerships

We actively collaborate with prestigious universities, research institutes, and renowned factories across Asia and Europe. Our partnerships with industry giants such as Panasonic, SIEMENS, CSIC, SAMSUNG, and HUAWEI allow us to stay at the forefront of innovation and technological advancement. These collaborations enhance our product development capabilities, ensuring we meet the evolving demands of the market.

Quality Assurance and Supply Chain Management

Our industry-leading quality system covers the entire supply chain, from raw materials to final delivery. This comprehensive approach guarantees that each product meets rigorous quality standards and adheres to stringent testing protocols. We implement standard operating procedures to ensure consistent quality and timely delivery, with complete traceability achieved through our full ISO-9001 compliance.

Commitment to Excellence

Our S.Q.D.I.P. system—emphasizing Safety, Quality, Delivery, Inventory, and Performance—drives our relentless pursuit of excellence. This structured approach allows us to continually refine our processes and enhance product reliability, ensuring our customers receive only the best.

Innovative Labs and Testing Solutions

Grand’s innovative labs are equipped to provide comprehensive testing and verification solutions. Our facilities are designed to rigorously assess product performance under various conditions, ensuring that our slip rings deliver reliable and high-performance results across diverse applications.

Interested in customizing your High Voltage/High Current Slip Rings? Enter your details below and receive expert advice from our specialists.

Related Posts

FAQs about High Voltage/High Current Slip Ring

Does high voltage cause high current?

High voltage and high current are related concepts in electrical systems, but one does not inherently cause the other. According to Ohm’s Law (V = IR), voltage (V) is equal to the current (I) multiplied by the resistance (R) of the circuit. Therefore, if the resistance remains constant, increasing the voltage will indeed lead to an increase in current. However, in practical applications, high voltage systems can operate at low currents if the load has a high resistance. For instance, in power transmission systems, high voltages are used to minimize energy loss due to resistance in the wires. Conversely, low voltage systems can produce high currents if the resistance is low. This relationship is crucial in designing electrical systems to ensure safety and efficiency, particularly in applications like slip rings, where understanding the dynamics between voltage and current is essential for effective power and signal transmission.

What voltage is a slip ring?

The voltage rating of a slip ring varies significantly depending on its design and intended application. Slip rings are engineered to facilitate the transfer of electrical power and signals between stationary and rotating parts, which can include a wide range of voltage levels. For instance, miniature slip rings may handle voltages up to 50V, while larger, high-current slip rings can support voltages ranging from 600V to over 10kV. It is essential to select a slip ring that matches the voltage requirements of your specific application to prevent overheating, signal loss, or damage to the slip ring itself. Always refer to the manufacturer’s specifications to ensure that the slip ring can safely and effectively handle the voltage levels you plan to use in your project.

What is the alternative to a slip ring?

While slip rings are widely used for transferring power and signals in rotating applications, there are several alternatives depending on the specific requirements of the application. One popular alternative is contactless transmission methods, such as inductive coupling or wireless transmission technologies like Bluetooth or RF signals. These methods eliminate physical connections, thus reducing wear and tear. However, they may not be suitable for high power applications and can suffer from interference issues. Another option is the use of rotary transformers, which allow for power transfer without mechanical contacts, providing a longer lifespan and maintenance-free operation. Additionally, specialized connectors and swivels may be utilized for certain applications where movement is limited. Each alternative comes with its own set of advantages and limitations, making it essential to evaluate your specific needs when considering options.

What are the different types of slip rings?

Slip rings come in various types, each designed for specific applications and operational requirements. The most common types include:

Miniature Slip Rings: These are compact devices ideal for applications with limited space, such as in medical equipment or small robotic systems.

High Current Slip Rings: Designed to handle high power transmission, these slip rings are used in heavy machinery and industrial applications.

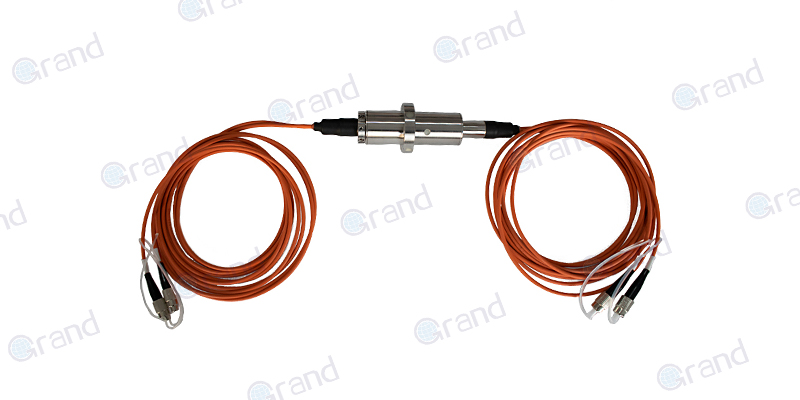

Fiber Optic Slip Rings: These specialized slip rings allow for the transmission of optical signals, making them suitable for telecommunications and data transmission applications.

Wireless Slip Rings: Employing wireless technology, these slip rings eliminate the need for physical connections, providing flexibility in design and operation.

Multi-channel Slip Rings: Capable of transmitting multiple signals through a single device, these are beneficial in complex systems requiring data, power, and control signals.