Introduction

In our technologically advanced world, understanding slip ring circuit ratings can become a key factor in managing and optimizing the performance of a diverse range of machinery. From alternative energy generation to sophisticated medical devices, slip ring circuit ratings hold substantial influence. In this article, we delve deep into the heart of slip ring circuit ratings, unraveling their significance, factors to consider when choosing the right ratings, their various applications, the correlation with short circuits, detailed data on different types of slip rings, and frequently asked questions on the topic. By the end of this comprehensive guide, you’ll possess a well-rounded understanding of slip ring circuit ratings, enhancing your capability to make wise, informed decisions in your respective electrical applications.

What Are Slip Ring Circuit Ratings?

Slip ring circuit ratings refer to specific electrical parameters that characterize slip rings, otherwise known as rotary electrical connectors. These parameters are fundamental in defining the slip ring’s performance and the operation of the machines where they are integrated. Here, we further delve into the four primary electrical factors that form a slip ring circuit rating:

Voltage

Voltage, or electrical potential difference, is a key parameter that decides the amount of electrical force a slip ring can endure before breaking down. Measured in volts (V), the voltage rating can cover both Alternating Current (AC) or Direct Current (DC) depending on the slip ring’s application. The voltage rating contributes significantly to the slip ring’s power handling capabilities. An optimally chosen voltage rating is crucial to prevent voltage breakdowns, which can potentially cause damage to the entire electrical system.

Current

The current rating signifies the amount of electrical current the slip ring can transmit without leading to overheating, subsequent damage, or efficiency loss. Defined in amperes (A), the current rating is essentially the slip ring’s capacity to carry current. High-current applications need slip rings with high current ratings to avoid overheating and prevent early wear and tear. Properly handling current ratings reduces resistive losses within the slip ring, contributing to better efficiency and performance.

Insulation Resistance

Insulation resistance tests the insulating material’s ability to resist electrical conduction between circuits. It is quantified in megaohms (MΩ) or gigaohms (GΩ). Larger insulation resistance ensures safer operation, as low resistance can lead to short circuits or other electrical failures. While high insulation resistance might increase costs, it provides the essential function of preventing unwanted electrical paths and promotes overall equipment safety.

Dielectric Strength

The dielectric strength of an insulator reflects its ability to withstand high voltage without breaking down. Measured in volts per unit thickness, typically kilovolts per millimeter (kV/mm), it’s necessary for an insulator to have a high dielectric strength to safeguard against unexpected high voltage spikes. Slip rings with a higher dielectric strength rating won’t suffer material failure or a catastrophic breakdown during voltage overloads. Thus, it enhances the longevity and reliability of the slip ring and the connected machinery.

In summary, understanding and considering the appropriate circuit ratings for slip rings in alignment with their specific applications is fundamental to ensuring efficiency, productivity, and durability in a wide variety of industrial systems.

How to Choose the Appropriate Slip Ring Circuit Ratings?

Determining the suitable slip ring circuit ratings demands a multilayered approach, factoring in performance requirements, application specifics, and safety considerations. Here are the four fundamental steps to guide you in choosing the proper slip ring circuit ratings suitable for your application:

Identify Your Application Requirements

The selection process begins with thoroughly understanding your system’s needs. You need to be cognizant of the machine’s function and its electrical and mechanical requirements. Factors to consider may include the application’s operating speed, voltage levels, current levels, and environmental conditions such as temperature and exposure to dust, moisture, or chemicals. Identifying your unique needs helps you stipulate the necessary circuit ratings to ensure the machine’s smooth operation and longevity.

Define the Slip Ring Performance Specifications

After identifying what your application needs, the next step is to determine the required slip ring voltage and current ratings that align with those necessities. These parameters lay the foundation for efficient system operation and often directly affect power transmission efficiency and overall system performance. Therefore, selecting the appropriate circuit ratings essential for the tasks at hand is a crucial step in the selection process.

Evaluate Insulation Resistance and Dielectric Strength

This step involves the assessment of the safety attributes of the slip ring based on your application requirement. The quality of materials used for insulation and dielectric strength should be such that they provide reliable operation and safety through their insulation and dielectric qualities. These parameters need to be selected based on environmental conditions like temperature, humidity, and air pressure, which can affect the insulation capacity and dielectric strength.

Consult Slip Ring Experts and Manufacturers

No one understands slip rings better than the professionals who design and produce them. After making preliminary decisions related to your requirements and performance specifications, it would be advantageous to consult with slip ring experts or manufacturers. They can provide guidance to fine-tune your decisions, ensuring optimum efficiency and operation of your slip ring based on circuit ratings most compatible with your application.

Overall, selecting proper slip ring circuit ratings is a culmination of understanding your application requirements, establishing performance specifications, assessing safety parameters, and engaging with slip ring experts. By following these steps, you can make informed decisions on your slip ring selection, ultimately enhancing your application’s overall performance and operational lifespan.

Application of Slip Ring Circuit Ratings with Different Values

Each application has unique requirements and demands; as such, the circuit ratings for slip rings vary significantly. Let’s consider four applications of slip rings with different circuit ratings:

Wind Turbines

Wind turbines deal with volatile power generation due to constantly changing wind speeds. This requires slip rings with higher voltage and current ratings to manage the changeable and often high power levels, ensuring efficient power transmission from the rotating blades to the stationary grid. The slip rings in wind turbines must also withstand challenging environmental conditions such as extreme temperatures, moisture, and dust.

Medical Equipment

Medical machines like MRI scanners and CT scanners demand high precision, reliability, and safety. They typically require slip rings with lower voltage and current ratings. However, owing to stringent safety requirements in the medical field, these applications demand very high insulation resistance values to ensure no leakage current can pose a risk to patients or medical staff.

Robotics and Automation

Robotics and automated systems are diverse in their requirements. They may require slip rings with multiple circuit ratings that cater to specific needs, such as signal transmission, power transmission, or data transfer. As these systems often involve quick, precise movements, the slip rings used must be able to maintain secure electrical connections despite constant motion, achieving high performance while ensuring minimal contact wear.

Marine and Aerospace

Slip rings used in marine and aerospace environments have higher dielectric strength, insulation resistance, and corrosion resistance. This is because they often encounter harsh environments with extreme temperatures, pressure variations, and exposure to corrosive agents. Marine slip rings have additional demands; they need circuit ratings that can withstand saltwater exposure, indicating the importance of considering environmental factors when choosing slip ring circuit ratings.

Each application poses unique challenges that slip ring circuit ratings need to meet. Understanding these specific needs is crucial to choosing slip rings that offer high performance, reliability, and durability across a variety of situations and applications.

Slip Ring Circuit Ratings and Slip Ring Short Circuit

Short circuits occur when a path of negligible or zero electrical impedance emerges, causing a sudden surge of current. When related to slip rings, a short circuit can occur if there’s a breakdown of insulation resistance between two conductive paths. The circuit rating of a slip ring plays a vital role in preventing such unwanted electrical occurrences. Let’s take a deeper look at the connection between slip ring circuit ratings and short circuits:

The insulation resistance and dielectric strength of a slip ring, two critical factors in the circuit rating, have a direct impact on the likelihood of a short circuit. A slip ring with a high insulation resistance rating is less likely to suffer from a short circuit since the insulating material adequately separates the circuits. However, factors such as wear and tear, accumulation of dust or grime on the contact surfaces, or degradation due to harsh environmental factors can decrease insulation resistance over time, meaning regular maintenance is essential to prevent short circuits.

Dielectric strength is another critical aspect in preventing short circuits within a slip ring. A slip ring with high dielectric strength can deter electrical breakdown, which happens when the insulation material fails due to high voltage levels. In such scenarios, a short circuit may ensue, causing significant damage and bringing the machinery to a standstill.

Appropriate circuit ratings aid a lot in minimizing the chance of a short circuit. Choosing a slip ring with suitable voltage and current ratings, high insulation resistance, and dielectric strength can significantly reduce the possibility of short circuits and uphold the standard of its operation.

Despite having a slip ring with suitable circuit ratings, short circuits may still occur if the slip ring is poorly maintained or operated under unsuitable environmental conditions. Hence, besides choosing a slip ring with appropriate circuit ratings, regular oversight, and maintenance are pivotal in maintaining their operation and longevity. In addition, slip ring materials should have resistance to environmental corrosion, heat, dust, or any other damaging factors present in their working environment.

Slip Ring Circuit Rating Data of Different Types of Slip Rings

Different types of slip rings possess diverse circuit rating data depending on their applications and operational requirements. Here, we will describe four types of slip rings and their associated circuit ratings data:

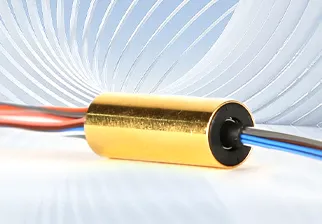

Capsule Slip Rings

These slip rings cater to compact applications demanding space-saving and lightweight solutions. They are appropriate for systems that require minimal diameter or height, such as medical equipment, robotics, and miniature automation systems. The circuit ratings for these slip rings typically involve low voltage and current levels, providing reliable signal and power transmission with minimal electrical noise. Their dielectric strength and insulation resistance values adapt to the specific application, considering factors like space constraint, temperature, and humidity effects.

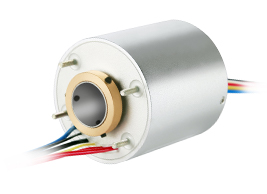

Through Bore Slip Rings

Through bore slip rings are designed to accommodate a passage through their center, allowing for the integration of additional mechanical components such as a hydraulic or pneumatic system. They are primarily used in wind turbines, gantry cranes, and heavy machinery applications, where space constraints are lesser. Through bore slip rings usually have higher voltage and current ratings to handle significant power transmission requirements. They must also possess elevated insulation resistance and dielectric strength values to avoid electrical breakdowns during demanding operational settings.

Model | Picture | No. of Rings | ID(mm) | OD(mm) | Rated Current | Rated Voltage | |

1-12 | 12 | 33 | 2A | 0~240V | |||

1-24 | 12 | 54 | 5A | 0~240V | |||

1-10 | 20 | 60 | 2A~10A | 0~380V | |||

1-48 | 25.4 | 78 | 2A~10A | 0~380V | |||

1-48 | 38.1 | 99 | 2A~15A | 0~380V | |||

1-10 | 50 | 75 | 2A~12A | 0~380V | |||

1-72 | 50 | 120 | 5A~20A | 0~380V | |||

1-96 | 60 | 135 | 5A~20A | 0~380V | |||

1-96 | 70 | 155 | 5A~20A | 0~380V | |||

1-96 | 80 | 180 | 5A~20A | 0~380V | |||

1-96 | 90 | 190 | 5A~20A | 0~380V | |||

1-96 | 100 | 203 | 5A~20A | 0~380V | |||

1-96 | 120 | 250 | 5A~20A | 0~380V | |||

1-96 | 150 | 300 | 5A~20A | 0~380V | |||

1-96 | 180 | 332 | 5A~20A | 0~380V | |||

1-96 | 200 | 350 | 5A~20A | 0~380V | |||

1-96 | 250 | 407 | 5A~20A | 0~380V | |||

1-96 | 300 | 490 | 5A~20A | 0~380V | |||

1-96 | 400 | 632 | 5A~20A | 0~380V |

Miniature slip rings

A miniature slip ring assembly is specially designed for small installation spaces. Also called a small slip ring, mini slip ring, compact slip ring, or micro slip ring. A miniature slip ring is the extension of a capsule slip ring and through the through-bore slip ring. The miniature package units have been designed to offer an economical and compact solution for signal and power transmission between the rotor and stator side. Shaft or flange are the two main mounting methods.

PIN Slip Rings

PIN slip rings are the substitute for mercury slip rings. Mercury slip rings use liquid metal mercury as the transmission medium. Special sealing technology, insulation, and compact design made them outstanding features like extremely long working life, low electrical noise, and contact resistance. Mercury is a chronic toxic substance. There have great potential threat to both the environment and the operators if leaked. People have been actively searching for alternative products.

Model | Picture | No. of Rings | OD(mm) | Rated Current | RPM | IP | |

2 | 32 | 20A | 0~400 | IP54 | |||

2 | 32 | 20A | 0~400 | IP65 | |||

2 | 32 | 20A | 0~400 | IP68 | |||

3 | 32 | 5A/20A | 0~400 | IP54 | |||

3 | 32 | 5A/20A | 0~400 | IP65 | |||

3 | 32 | 5A/20A | 0~400 | IP68 | |||

4 | 32 | 5A/20A | 0~400 | IP54 | |||

4 | 32 | 5A/20A | 0~400 | IP65 | |||

4 | 32 | 5A/20A | 0~400 | IP68 | |||

5 | 32 | 5A/20A | 0~400 | IP54 | |||

5 | 32 | 5A/20A | 0~400 | IP65 | |||

5 | 32 | 5A/20A | 0~400 | IP68 |

High Temperature Slip Ring

The slip ring can work stably under a 100~250℃ high-temperature environment, even above 250℃.

Model | No. of Rings | ID(mm) | OD(mm) | Rated Current | Rated Voltage | |

1-12 | 12.0 | 33.0 | 2A | 0~240V | ||

1-24 | 12.7 | 54.0 | 5A | 0~240V | ||

1-10 | 20.0 | 60.0 | 2A~10A | 0~380V | ||

1-48 | 25.4 | 78.0 | 2A~10A | 0~380V | ||

1-48 | 38.1 | 99.0 | 2A~15A | 0~380V | ||

1-72 | 50.0 | 120.0 | 5A~20A | 0~380V | ||

1-96 | 60.0 | 135.0 | 5A~20A | 0~380V | ||

1-96 | 70.0 | 155.0 | 5A~20A | 0~380V | ||

1-96 | 80.0 | 180.0 | 5A~20A | 0~380V | ||

1-96 | 90.0 | 190.0 | 5A~20A | 0~380V | ||

1-96 | 100.0 | 203.0 | 5A~20A | 0~380V | ||

1-96 | 120.0 | 250.0 | 5A~20A | 0~380V | ||

1-96 | 150.0 | 300.0 | 5A~20A | 0~380V | ||

1-96 | 180.0 | 332.0 | 5A~20A | 0~380V | ||

1-96 | 200.0 | 350.0 | 5A~20A | 0~380V | ||

1-96 | 250.0 | 407.0 | 5A~20A | 0~380V | ||

1-96 | 300.0 | 490.0 | 5A~20A | 0~380V | ||

1-96 | 400.0 | 632.0 | 5A~20A | 0~380V |

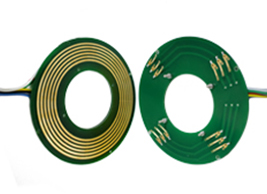

PCB Slip Ring

PCB slip ring is a kind of pancake slip ring, also called ultrathin flat slip ring. A common form of flat slip ring and made up of two parts, ring surface and brush assembly. The ring surface circuit board with an ultra-thick copper layer, then copper plating, and hard gold plating, so the PCB slip rings have high hardness and wear resistance features.

High Voltage/High Current Slip Ring

High-current slip rings and high-voltage slip rings are used for communication devices, large machining centers, antenna radar systems, large cranes, mining machines, and large cable reels. High voltage sometimes requires more than 2,000 volts and high current sometimes requires 500 amperes.

Model | ID(mm) | OD(mm) | No. of Rings | Max Rated Current | |

50 | 135 | 4 | 280A | ||

66 | 202 | 20 | 500A | ||

70 | 176 | 8 | 100A | ||

75 | 185 | 98 | 1000A | ||

75 | 190 | 4 | 400A | ||

80 | 180 | 3 | 250A |

The circuit ratings data for different types of slip rings will vary based on their specific designs, intended applications, and the unique challenges they address. Understanding these distinctions and the requirements of your application is crucial to selecting the most appropriate slip ring with suitable circuit ratings for optimal performance.

Conclusion

The function and performance of slip rings significantly depend on their circuit ratings, which should align with specific application requirements. When selecting the appropriate slip ring for an application, it is crucial to consider the machine’s function, and its needs for voltage, current, insulation resistance, and dielectric strength.

Several domains including wind turbines, medical equipment, robotics, and marine and aerospace applications implement slip rings with different circuit ratings to cater to their unique needs. Similar to how wind turbines require higher voltage and current ratings to manage high power levels, medical devices need slip rings with high insulation resistance due to stringent safety measures.

The circuit ratings also play a significant role in preventing short circuits in slip rings. Higher insulation resistance and dielectric strength in slip rings help prevent the likelihood of a short circuit, maintaining the efficiency of operations.

Different types of slip rings such as compact capsule slip rings, through bore slip rings, pancake slip rings, and Fiber Optic Rotary Joints possess diverse circuit ratings, each serving their unique application and operational requirements.

In conclusion, understanding your application’s needs and the associated circuit ratings is essential for selecting the most suitable slip ring. This understanding, coupled with regular maintenance and operation under proper environmental conditions, can greatly enhance the performance and lifespan of your application, proving the importance of appropriate slip ring circuit ratings.

FAQ About Slip Ring Circuit Ratings

Q: Can I use a slip ring with higher circuit ratings than what my application requires?

A: Yes, using a slip ring with higher circuit ratings than needed generally does not pose an issue. However, it might be cost-ineffective, as slip rings with higher ratings tend to be more expensive.

Q: Do slip ring circuit ratings change over time?

A: Yes, slip ring circuit ratings can change over time due to wear and tear, environmental factors, and material degradation. Regular inspection and maintenance can help identify these changes and prolong the slip ring’s lifespan.

Q: How can I improve the insulation resistance of a slip ring?

A: Improving the insulation resistance of a slip ring can be achieved by selecting high-quality materials, ensuring proper installation, maintaining cleanliness, and protecting it from environmental factors like moisture and dust.

Q: How do I know if my slip ring’s circuit ratings are adequate for my application?

A: You can consult with slip ring experts or manufacturers, provide them with your application’s requirements, and seek their assistance in selecting the proper slip ring circuit ratings.